Method for low-energy consumption acetic acid hydrogenation production of ethanol

A low energy consumption, acetic acid technology, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of hydroxyl compounds, etc., can solve problems affecting the separation effect of the distillation tower, the pressure of the distillation tower, and the quality of ethanol products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

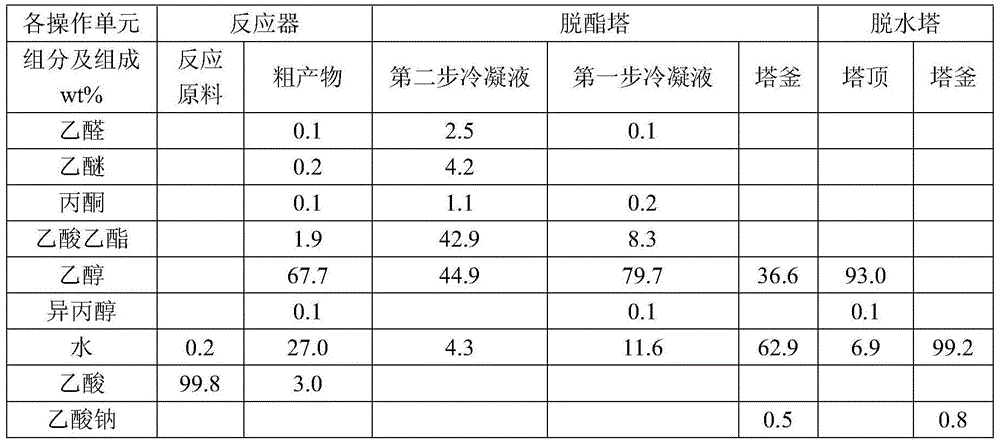

Embodiment 1

[0045] In this embodiment, the catalyst for acetic acid hydrogenation is the acetic acid hydrogenation catalyst produced by Beijing Research Institute of Chemical Industry, the brand is BC-E-20, and the catalyst contains: (1) cobalt, wherein the cobalt metal content accounts for 30wt% of the total weight of the catalyst ; (2) molybdenum and chromium, respectively accounted for 2wt% of the total weight of the catalyst; the balance is silicon oxide. The catalyst is prepared by co-precipitation.

[0046] The method for producing ethanol from acetic acid comprises the steps of:

[0047] (1) Hydrogenation: Preheat the acetic acid raw material and hydrogen, then make it pass through a reactor equipped with a hydrogenation catalyst, and hydrogenate acetic acid into crude ethanol product; the process condition of acetic acid hydrogenation is: the liquid phase volume of acetic acid The speed is 0.5h -1 , the molar ratio of hydrogen to acetic acid is 20:1, the reaction temperature is ...

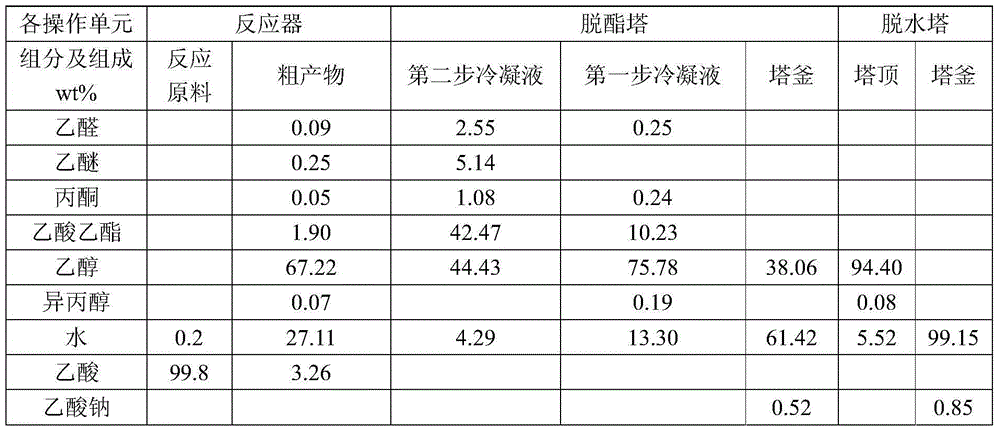

Embodiment 2

[0053]In this embodiment, the catalyst for acetic acid hydrogenation is the acetic acid hydrogenation catalyst produced by Beijing Research Institute of Chemical Industry, the brand is BC-E-20, and the catalyst contains: (1) cobalt, wherein the cobalt metal content accounts for 30wt% of the total weight of the catalyst ; (2) molybdenum and chromium, respectively accounted for 2wt% of the total weight of the catalyst; the balance is silicon oxide. The catalyst is prepared by co-precipitation.

[0054] The method for producing ethanol from acetic acid comprises the steps of:

[0055] (1) Hydrogenation: Preheat the acetic acid raw material and hydrogen, then make it pass through a reactor equipped with a hydrogenation catalyst, and hydrogenate acetic acid into crude ethanol product; the process condition of acetic acid hydrogenation is: the liquid phase volume of acetic acid The speed is 0.75h -1 , the molar ratio of hydrogen to acetic acid is 15:1, the reaction temperature is ...

Embodiment 3

[0061] In this embodiment, the catalyst for acetic acid hydrogenation is the acetic acid hydrogenation catalyst produced by Beijing Research Institute of Chemical Industry, the brand is BC-E-20, and the catalyst contains: (1) cobalt, wherein the cobalt metal content accounts for 30wt% of the total weight of the catalyst ; (2) molybdenum and chromium, respectively accounted for 2wt% of the total weight of the catalyst; the balance is silicon oxide. The catalyst is prepared by co-precipitation.

[0062] The method for producing ethanol from acetic acid comprises the steps of:

[0063] (1) Hydrogenation: Preheat the acetic acid raw material and hydrogen, then make it pass through a reactor equipped with a hydrogenation catalyst, and hydrogenate acetic acid into crude ethanol product; the process condition of acetic acid hydrogenation is: the liquid phase volume of acetic acid The speed is 1.25h -1 , the molar ratio of hydrogen to acetic acid is 12:1, the reaction temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com