Base film used for transparent electrode film and transparent electrode film using the same

A technology of transparent electrode film and transparent substrate, used in conductive materials, conductive materials, circuits, etc., can solve the problems of unsuitability for touch panels, hard coatings are easy to yellow, and achieve excellent transparency, heat resistance and Excellent dimensional stability and improvement of deterioration phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

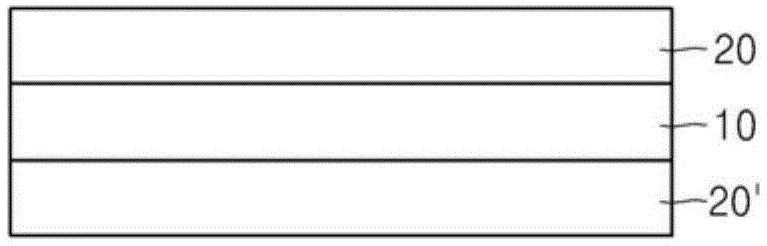

[0047](1) Preparation of substrate film

[0048] Utilize the gravure coating method to form a 300nm polyamide layer on one side of a polyethylene terephthalate (PET, polyethyleneterephthalate) film with a thickness of 100um, and utilize the gravure coating method to coat the above polyethylene terephthalate The opposite side forms a 3um hard coating.

[0049] The polyamide layer-forming resin composition used at this time was prepared by mixing solid polyamide with ethanol.

[0050] (2) Preparation of transparent electrode film

[0051] A coating composition containing poly(3,4-ethylenedioxythiophene) as an active ingredient is coated on the upper surface (polyamide layer) of the substrate film prepared above, and dried to form a conductive film with a thickness of 200 nm. The polymer transparent electrode layer is used to prepare a transparent electrode film.

Embodiment 2

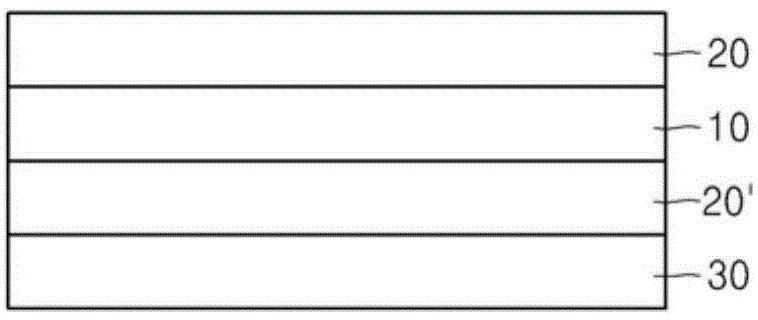

[0053] (1) Preparation of substrate film

[0054] A 300 nm polyamide layer was formed on one side of a polyethylene terephthalate film having a thickness of 100 um by gravure coating, and a 3 um hard coat layer was formed on the underside of the polyamide layer by gravure coating.

[0055] (2) Preparation of transparent electrode film

[0056] Coating a coating composition comprising poly(3,4-ethylenedioxythiophene) as an active ingredient on the base film prepared above, and drying to form a conductive polymer transparent electrode layer with a coating film thickness of 200 nm , to prepare a transparent electrode film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com