Ultra-temperature CNTs/TiB2-SiC ceramic composite material and preparation method thereof

A ceramic composite material, tib2-sic technology, which is applied in the field of ultra-high temperature CNTs/TiB2-SiC ceramic composite material and its preparation, can solve the problems of inability to break through fracture toughness and restriction of thermal shock resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

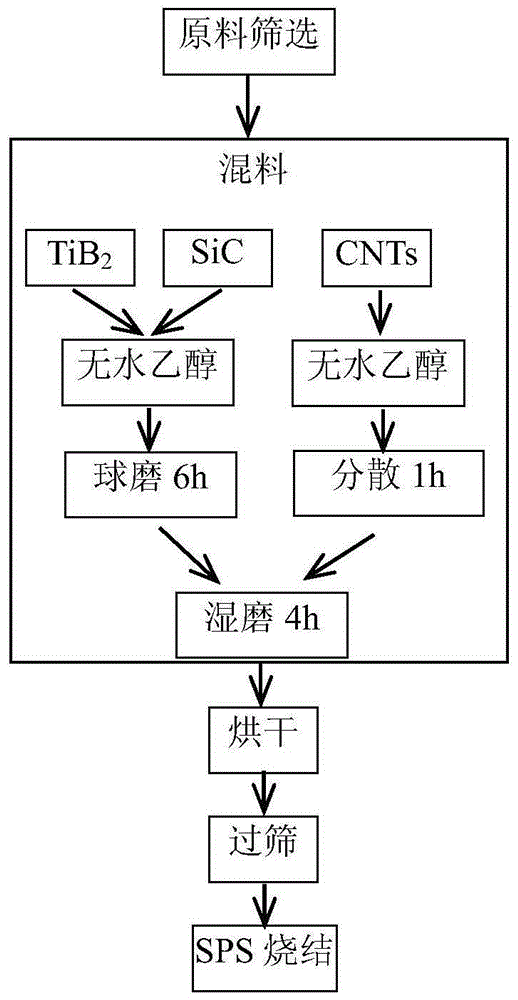

[0037] An ultra-high temperature CNTs / TiB of the present invention 2 -The preparation method of SiC ceramic composite material includes:

[0038] S1: mixing step, firstly mixing titanium boride powder, silicon carbide powder and carbon nanotube powder to obtain a mixed powder of titanium diboride, silicon carbide and carbon nanotube powder; and

[0039] S2: a sintering step, sintering the mixed powder through a spark plasma sintering molding process to obtain the CNTs / TiB 2 -SiC ceramic composite material.

[0040] The S1 step can include:

[0041] S11: mixing step, mixing and drying titanium diboride powder, carbon nanotube powder and silicon carbide powder to obtain a dried mixed powder; and

[0042] S12: Grinding, grinding and sieving the dry mixed powder to obtain a uniformly mixed mixed powder.

[0043] In step S11, the average particle size of the titanium diboride powder is 10 nm to 50 nm, preferably 20 nm; and / or, the average particle size of the silicon carbide powder is 40 nm t...

Embodiment 1

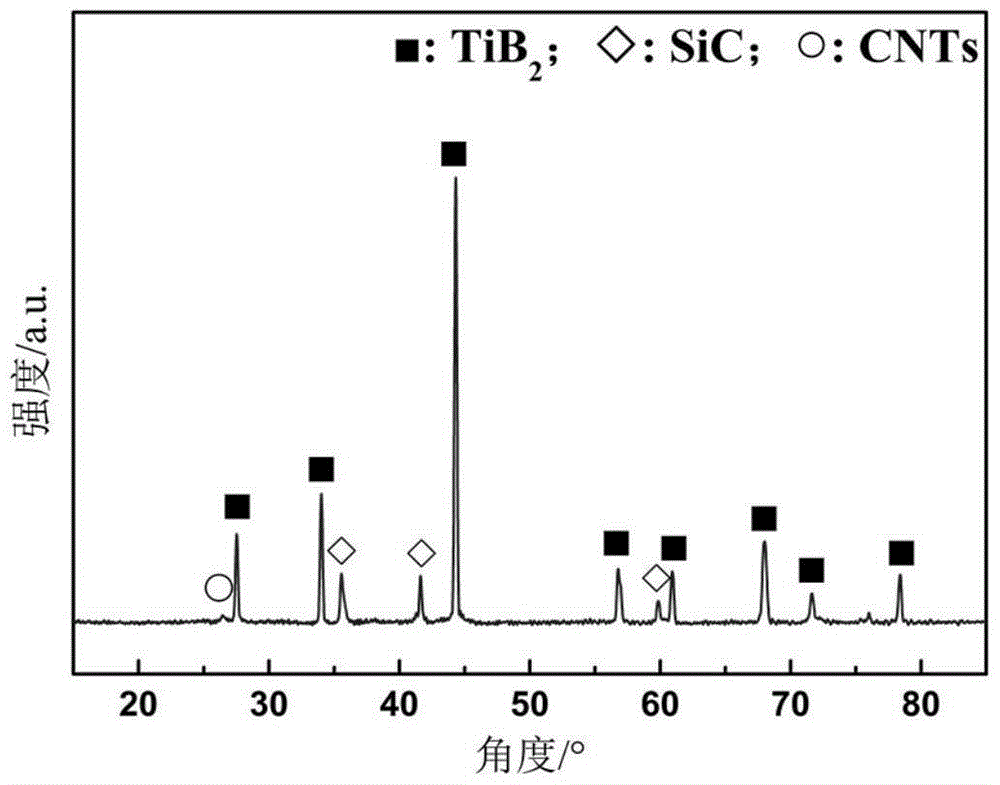

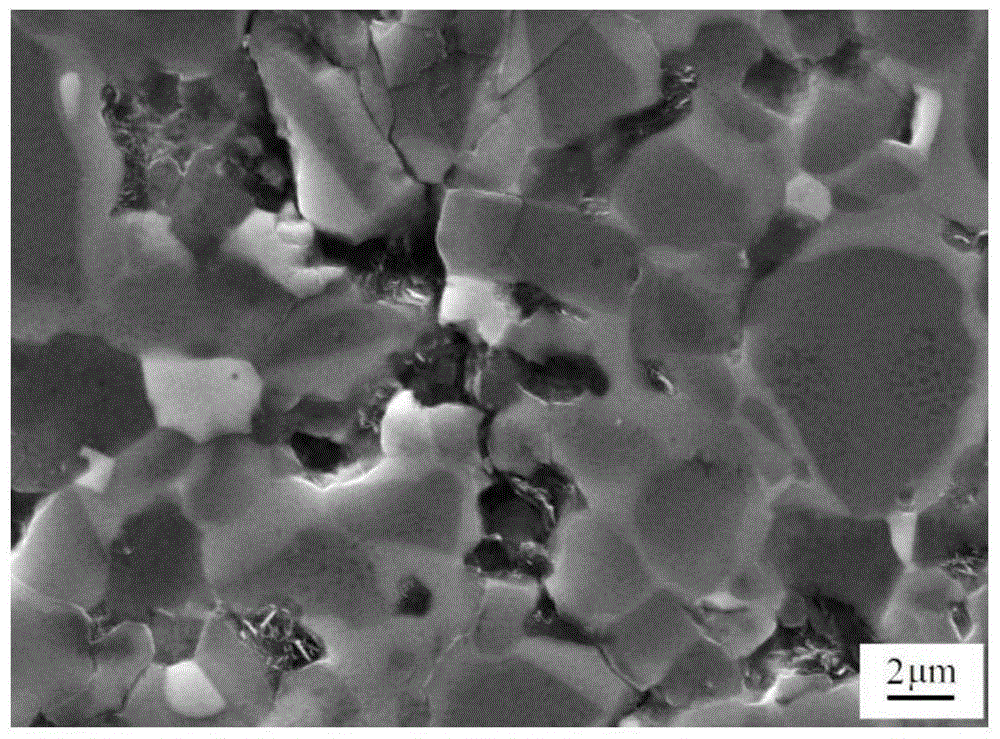

[0059] According to the conventional process, the raw material powder is weighed according to the required proportion: using commercially available TiB 2 Powder, SiC powder, CNTs as raw materials, the purity of the powder is higher than 99%; TiB 2 The volume fractions of SiC powder and CNTs are 70%, 15% and 15%, respectively.

[0060] Using planetary ball mill for TiB 2 It is mixed with SiC powder. To prevent impurities from being mixed, ZrO with higher hardness and better chemical stability is used 2 The dispersion medium is anhydrous ethanol, and the spherical mass ratio is 10:1. First put TiB 2 After mixing with SiC, ball mill for 6 hours, at the same time disperse CNTs in absolute ethanol, vibrate with ultrasonic for 1 hour, after the two are mixed, continue wet grinding for 4 hours. Then CNTs / TiB 2 -The SiC slurry is placed on an evaporator to evaporate and dry, and finally placed in a constant temperature (80°C) drying oven for 24 hours.

[0061] The dried mixed powder is rep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com