Device for separating at least two adjacent strands of material and system including such device

A technology of equipment and spacers, which is applied in the field of manufacturing electrical energy storage composite belts, can solve the problems of reducing output, time-consuming and laborious, etc., and achieve the effect of avoiding breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Various embodiments of the present invention will now be described with reference to the accompanying drawings. In these different figures, the same elements have the same reference numerals.

[0065] 1. Manufacturing method

[0066] 1.1. general principles

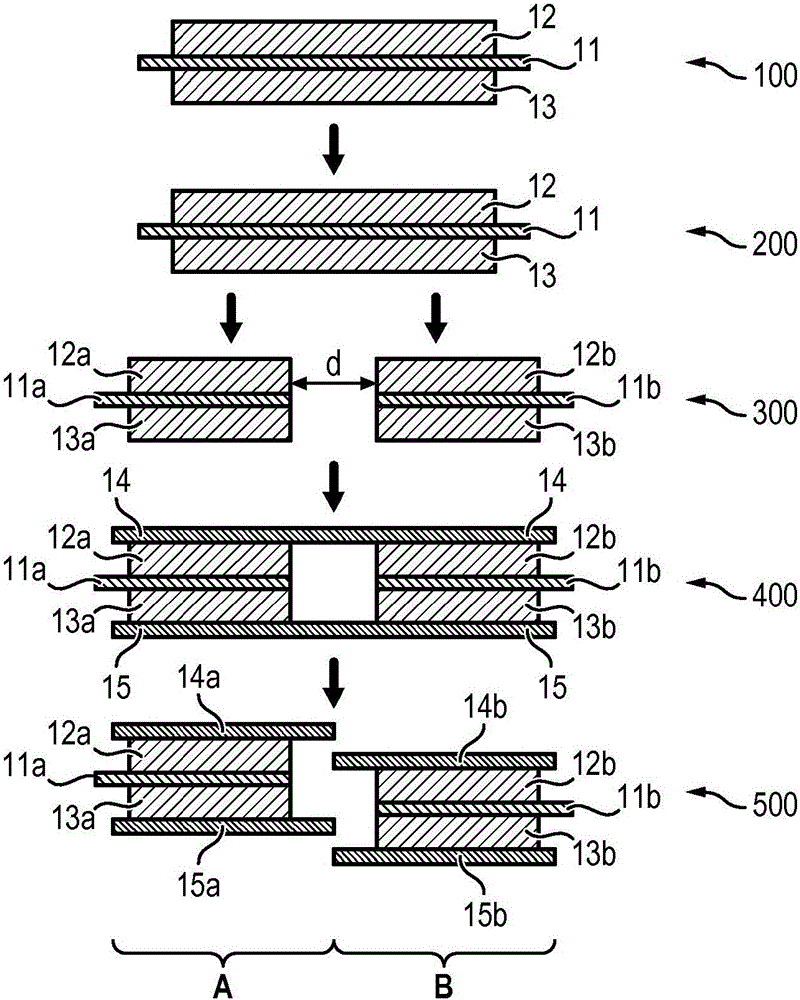

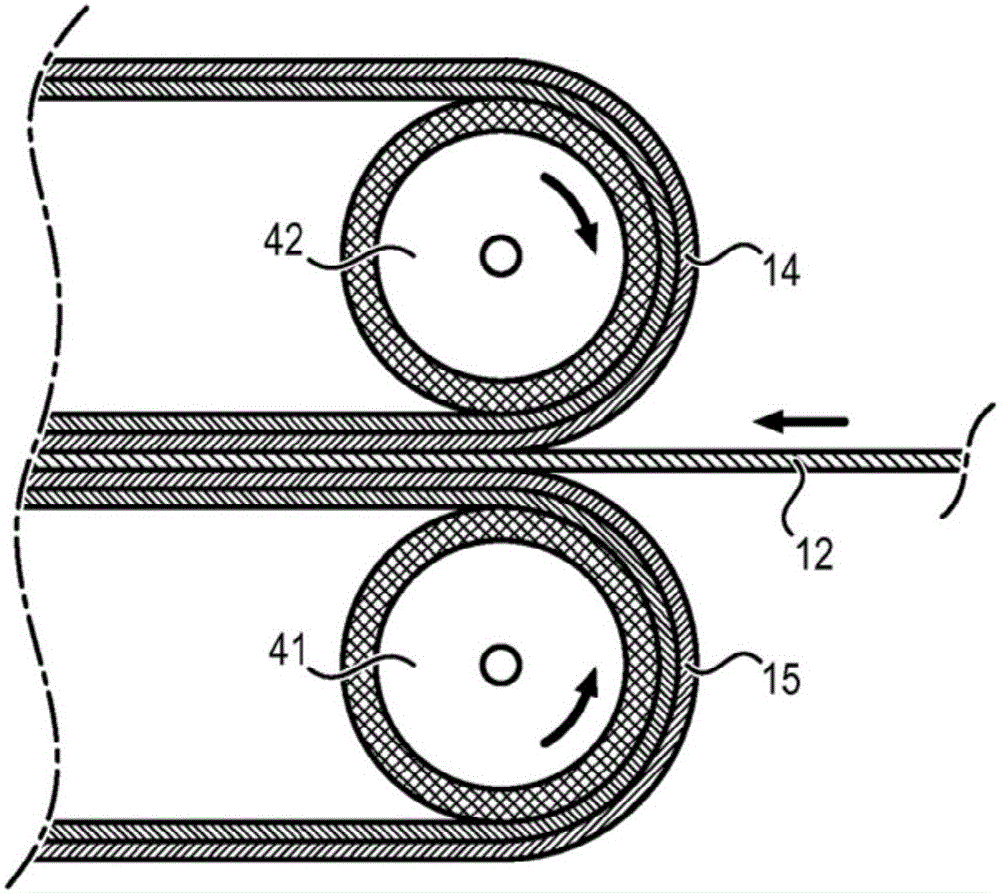

[0067] refer to figure 1 , shows the main steps of the method for fabricating electrical energy storage composite tapes.

[0068] The electrical energy storage composite strip may be all or part of an element capable of storing energy. In the embodiments described below, for example, the electrolyte and cathode of a cell are assembled and the anode is added in a later step using another device. The energy storage element can however be fabricated in one piece using the methods and apparatus described above.

[0069] Once the electrical energy storage composite ribbon is obtained, the ribbon can be used to fabricate an electrical energy storage unit comprising a portion of the ribbon such that the ribbon ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com