OCA (optically clear adhesive) optical membrane separation device

A separation device, optical film technology, applied in the direction of layered products, lamination, etc., can solve the problems of defective bonding quality, easy to be contaminated with dust, decreased adhesion, etc., to achieve clean surface, high separation efficiency, adhesion high quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

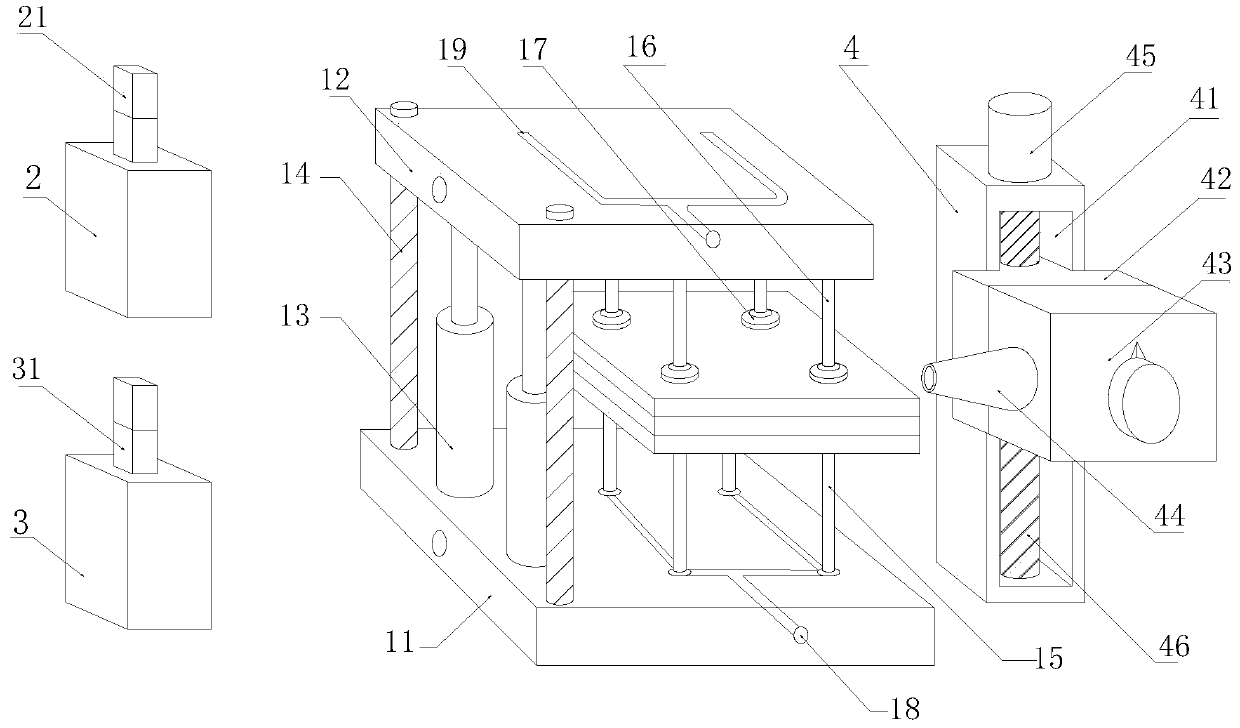

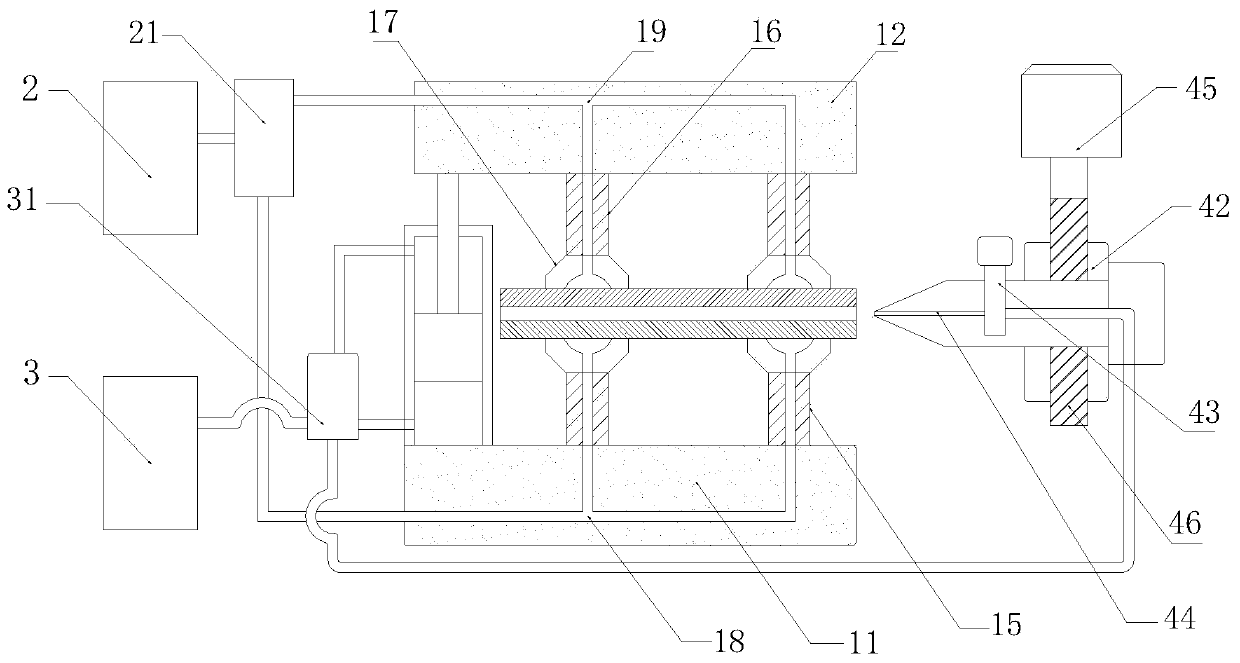

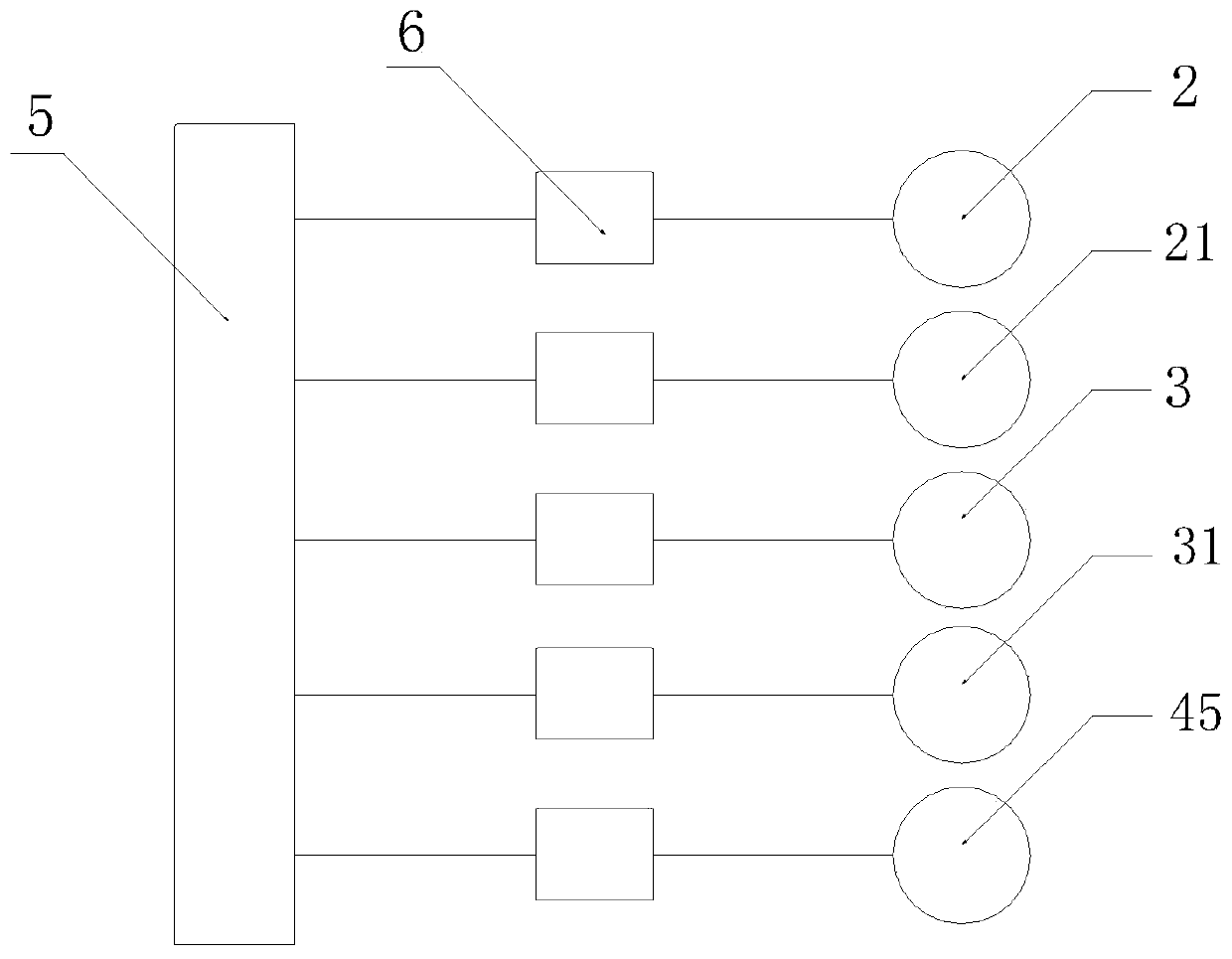

[0027] see Figure 1-3 , the present invention provides the following technical solutions: a kind of OCA optical film separation device, comprises separating machine platform 1, and separating machine platform 1 comprises a pair of fixed bottom plate 11 and lifting plate 12 parallel to each other, and the side of fixed bottom plate 11 and lifting plate 12 Through two flexible cylinders 13 and two guide columns 14, ten lower air guide tubes 15 are vertically installed on the top surface of the fixed base plate 11, and ten upper air guide tubes 16 and ten lower air guide tubes are vertically installed on the bottom surface of the lifting plate 12. 15 and ten upper airway tubes 16 are all arranged oppositely, and the opposite ends of the lower airway tube 15 and the upper airway tube 16 are all sleeved with silica gel suction cups 17 .

[0028] In this embodiment: the fixed bottom plate 11 is fixed on the work surface, and the two telescopic cylinders 13 drive the lifting plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com