Nylon 66/polyaminated bismaleimide composite for inner sheaths of heat-resisting power lines and preparation method of nylon 66/polyaminated bismaleimide composite

A technology based on maleimide and polyamino, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problem that the heat resistance cannot meet the market demand, achieve excellent mechanical properties, and improve flame retardant performance , the effect of improving interface performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

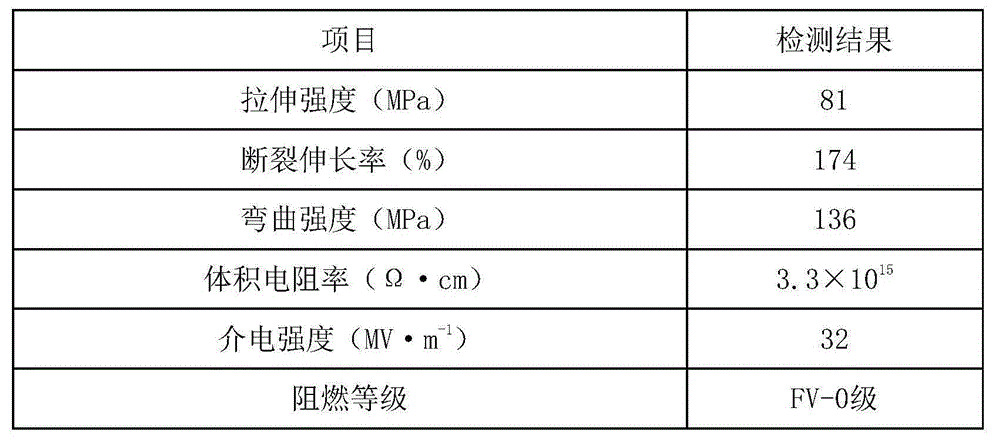

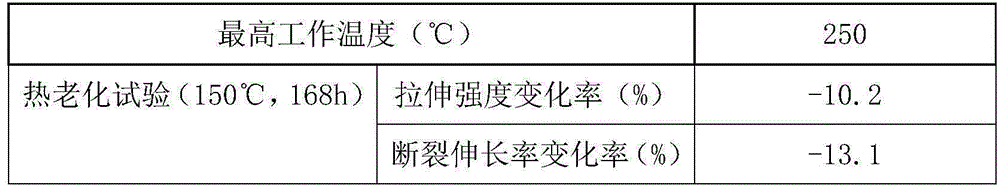

[0014] A kind of nylon 66 / polyaminobismaleimide composite material for the inner sheath of a heat-resistant power cord, made of the raw materials of the following weight (kg): nylon 6646, polyaminobismaleimide 22, poly( Bis(phenoxy)aphosphazene) 20, blast furnace slag powder 28, stannous chloride 3, N-methyl p-toluenesulfonamide 4, potassium fluorozirconate 8, dimethyl maleate 12, hydroxyl Zinc stannate 6, cuprous bromide 4, oxidized polyethylene wax 5, perfluoropolyether 7, colloidal graphite powder 20, flame retardant particles 23;

[0015] The preparation method of the flame-retardant particles is as follows: a, take the raw materials of the following weight (kg): colemanite 32, brucite 26, boehmite 18, expanded graphite 12, basic sodium aluminum carbonate 8, basic Magnesium chloride 7, brominated bisphenol A epoxy resin 28, pentabromobenzyl polyacrylate 30, hexaphenoxycyclotriphosphazene 12, dipentaerythritol diphosphite 8, chlorinated polyethylene 40; b, take hard boron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com