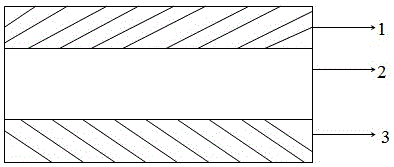

Heat radiation backboard for photovoltaic assembly

A photovoltaic module and heat dissipation backplane technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of inapplicability to large-scale applications, reduced component transportation, and unfavorable metal layers, and achieve high electrical insulation strength and reduced layers. Number, the effect of ensuring work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of insulating adhesive layer paint: In a container with a stirring device, add 100 parts of polyacrylic resin-propylene tertiary carbonate (parts by mass, the same below), 5 parts of isocyanate, 0.1 part of dibutyltin dilaurate, and the particle size is 1000 mesh 8 parts of glass fiber powder, 5 parts of solvent toluene, stir evenly, make adhesive layer coating liquid, set aside;

[0034] Preparation of weather-resistant layer coating: In a container with a stirring device, add 100 parts of vinylidene chloride resin, 15 parts of hexamethylene diisocyanate trimer, 5 parts of tetrabutyl titanate, 30 parts of alumina powder, and 30 parts of solvent toluene part, stir evenly to prepare a weather-resistant layer coating liquid, and set aside;

[0035] For an aluminum foil with a thickness of 80um, use a wire rod to evenly coat the above-mentioned insulating adhesive layer coating solution on one side, and then dry it in a drying oven at 120°C to form a film, and ...

Embodiment 2

[0037] Preparation of insulating bonding layer paint: In a container with a stirring device, add 100 parts of polyacrylic resin-propylene tertiary carbonate, 20 parts of amino resin, 5 parts of monobutyltin oxide, 30 parts of glass fiber powder with a particle size of 600 mesh, solvent two 30 parts of toluene, stirred evenly, made the bonding layer coating liquid, for subsequent use;

[0038] Preparation of weather-resistant coating: In a container with a stirring device, add 100 parts of vinyl fluoride-vinyl ether copolymer, 5 parts of hexamethylene diisocyanate prepolymer, 0.5 parts of cobalt isooctanoate, and 1 part of boron nitride powder, 5 parts of solvent xylene, stir evenly, make the bonding layer coating liquid, set aside;

[0039] Copper foil with a thickness of 100um, use a wire rod to evenly coat the above-mentioned insulating adhesive layer coating solution on one side, and then dry it in a 120°C drying oven to form a film, and control the thickness of the adhesiv...

Embodiment 3

[0041] Preparation of insulating adhesive layer paint: In a container with a stirring device, add 100 parts of polyacrylic resin-propylene tertiary carbonate, 12 parts of blocked isocyanate, 1 part of monobutyltin triisooctanoate, and glass fiber powder with a particle size of 400 mesh 15 parts, and 15 parts of ethyl acetate as a solvent, and stir evenly to prepare a bonding layer coating liquid, which is set aside.

[0042]Preparation of weather-resistant layer coating: In a container with a stirring device, add 100 parts of vinyl fluoride-vinyl ester copolymer, 13 parts of isophorone diisocyanate trimer, 4 parts of zinc naphthenate, 25 parts of magnesium oxide powder, Solvent ethyl acetate 25 parts, stir evenly, make weather-resistant layer coating liquid, set aside;

[0043] For a tin foil with a thickness of 200um, use a wire rod to evenly coat the above-mentioned insulating adhesive layer coating solution on one side, and then dry it in a 120°C drying oven to form a film,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com