Preparation method of underwater LED lamp pouring sealant

A technology of LED lamps and potting glue, applied in the direction of adhesives, etc., can solve the problems of poor solvent resistance, achieve the effects of low cost, not easy to be poisoned, and improve adhesion and high temperature resistance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

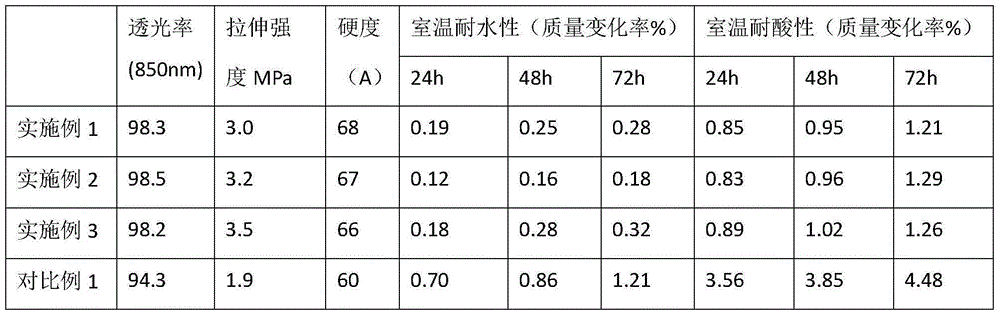

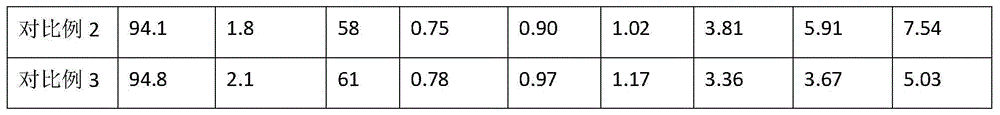

Examples

Embodiment 1

[0028] A preparation method for underwater LED lamp potting glue, said preparation method comprising:

[0029] S1: 20 parts by weight of 60% epoxyalkyl alkoxysilane, 10 parts of allyl triethoxysilane, 280 parts of methyliso Acetone, 5 parts of triethylamine, 60 parts of deionized water were added dropwise within 40 minutes under stirring at room temperature, hydrolysis and polycondensation reaction was carried out at reflux temperature of 60°C for 6 hours, the organic layer was separated, and 0.2wt% ammonium salt solution and deionized water were used to Wash and distill under reduced pressure at 80°C to obtain component A, a colorless, transparent viscous liquid;

[0030] S2: 20 parts by weight of phenyltrimethyloxysilane and 1 part of trifluoromethanesulfonic acid were added dropwise to 10 parts of deionized water within 20 minutes while stirring at room temperature, heated to reflux for 1 hour, and cooled to room temperature. Add toluene and water to wash, and distill unde...

Embodiment 2

[0034] A preparation method for underwater LED lamp potting glue, said preparation method comprising:

[0035] S1: 40 parts by weight of 3-functional chain segment fraction of 80% epoxyalkyl alkoxysilane, 15 parts of allyltriethoxysilane, 320 parts of methyliso Acetone, 10 parts of triethylamine, 80 parts of deionized water were added dropwise within 40 minutes under stirring at room temperature, hydrolyzed and polycondensed for 10 hours at reflux temperature of 80°C, the organic layer was separated, and 0.2wt% ammonium salt solution and deionized water were used to Wash and distill under reduced pressure at 120°C to obtain component A, a colorless, transparent viscous liquid;

[0036] S2: 40 parts by weight of phenyltrimethyloxysilane and 2 parts of trifluoromethanesulfonic acid were added dropwise to 20 parts of deionized water within 30 minutes while stirring at room temperature, heated to reflux for 2 hours, and cooled to room temperature. Add toluene and water to wash, a...

Embodiment 3

[0040]A preparation method for underwater LED lamp potting glue, said preparation method comprising:

[0041] S1: 30 parts by weight of 30 parts of epoxy alkyl alkoxysilane, 12 parts of allyl triethoxysilane, 300 parts of methyl iso Acetone, 8 parts of triethylamine, 70 parts of deionized water were added dropwise within 40 minutes under stirring at room temperature, and the hydrolysis and polycondensation reaction was carried out at reflux temperature of 70°C for 8 hours. Wash and distill under reduced pressure at 100°C to obtain component A, a colorless, transparent viscous liquid;

[0042] S2: 30 parts by weight of phenyltrimethyloxysilane and 1.5 parts of trifluoromethanesulfonic acid were added dropwise to 15 parts of deionized water within 25 minutes while stirring at room temperature, heated to reflux for 1.5 hours, and cooled to room temperature , add toluene and water to wash, and distill under reduced pressure at 70°C to obtain a Si-OH group-containing methylphenyls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com