Lanostane triterpenoid preparing method

A technology of lanosterane and triterpenoids, which is applied in the field of preparation of lanosterane triterpenoids, can solve the problems of long extraction process, large consumption of reagents, non-repeatable batches, etc., and achieve consistency High, high degree of automation of the instrument, and the effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

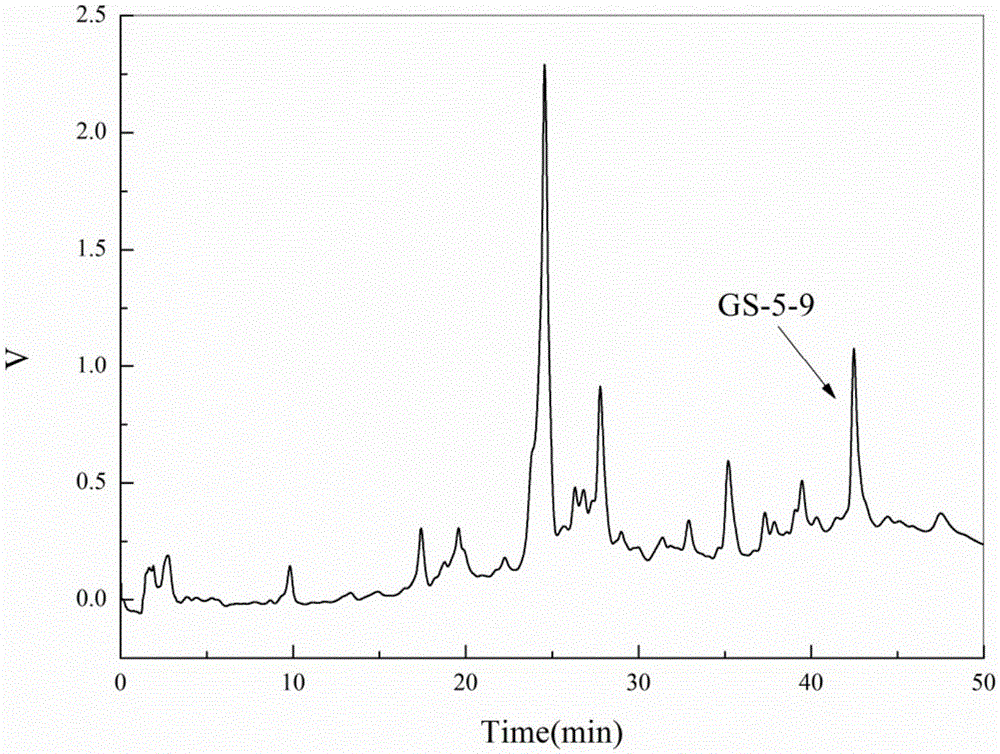

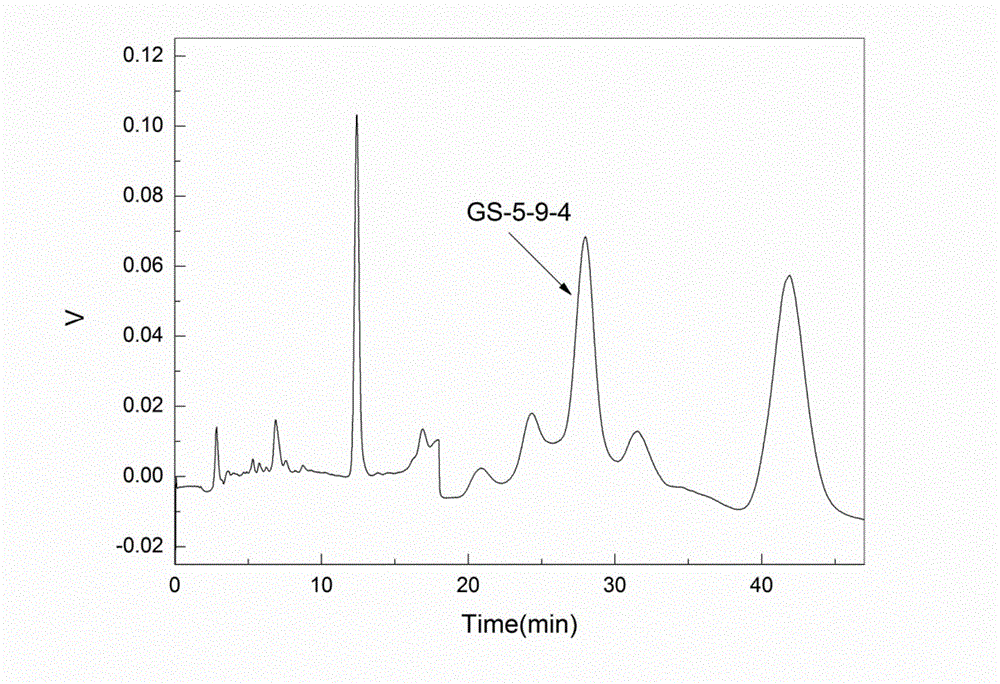

Embodiment 1

[0035] Take kansui as raw material, grind it into powder, soak it in ethyl acetate at room temperature for 5 hours, the solid-liquid ratio of kansui coarse powder to ethyl acetate is 1:8 in kg / L, stir intermittently, and extract continuously for 3 times , take the supernatant and concentrate it by distillation under reduced pressure. Choose a vacuum degree of 0.05Mpa and a temperature of 50°C to obtain a crude ethyl acetate extract in the form of an extract; weigh 350g and dissolve it in 3800mL of ethanol with a volume fraction of 30% ethanol -n-hexane solution, the obtained Kansui extract solution, the concentration is 92mg / mL, pass through a 0.45 μm microporous membrane, and carry out one-dimensional liquid chromatography preparation, the chromatographic column is Innovalsilica (250mm×150mm; 10 μm, ), the mobile phase is a binary mixed organic phase, wherein phase A is n-hexane, phase B is ethanol, gradient elution mode: 0-20% B elution 25min, 100% B elution 8min. Using a UV...

Embodiment 2

[0037] Take kansui as raw material, grind it into powder, soak it in ethyl acetate at room temperature for 5 hours, the solid-liquid ratio of kansui coarse powder to ethyl acetate is 1:10 in kg / L, stir intermittently, and extract continuously for 3 times , take the supernatant and concentrate it by distillation under reduced pressure, choose a vacuum degree of 0.05Mpa, and a temperature of 50°C to obtain a crude extract of ethyl acetate in the form of an extract; weigh 380g, dissolve it in 4000mL of ethanol with a volume fraction of 30% ethanol -n-hexane solution, the prepared Kansui extract solution, the concentration is 95mg / mL, passes through 0.45 μm microporous membrane, carries out one-dimensional liquid chromatography preparation, and chromatographic column is Innovalsilica (250mm×150mm; 10 μm, ), the mobile phase is a binary mixed organic phase, wherein phase A is n-hexane, phase B is ethanol, gradient elution mode: 0-20% B elution 25min, 100% B elution 8min. Using a U...

Embodiment 3

[0039] Take kansui as raw material, grind it into powder, soak it with ethyl acetate at room temperature for 5 hours, the solid-liquid ratio of kansui coarse powder to ethyl acetate is 1:9 in kg / L, stir intermittently, and extract continuously for 3 times , take the supernatant and concentrate it by distillation under reduced pressure, select a vacuum degree of 0.05Mpa, and a temperature of 50°C to obtain a crude ethyl acetate extract in the form of an extract; weigh 400g, dissolve it in 4500mL of ethanol with a volume fraction of 30% ethanol -n-hexane solution, the prepared Gansui extract solution, the concentration is 89mg / mL, passes through 0.45 μm microporous membrane, carries out one-dimensional liquid chromatography preparation, and chromatographic column is Innovalsilica (250mm×150mm; 10 μm, ), the mobile phase is a binary mixed organic phase, wherein phase A is n-hexane, phase B is ethanol, gradient elution mode: 0-20% B elution 25min, 100% B elution 8min. Using a UV ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com