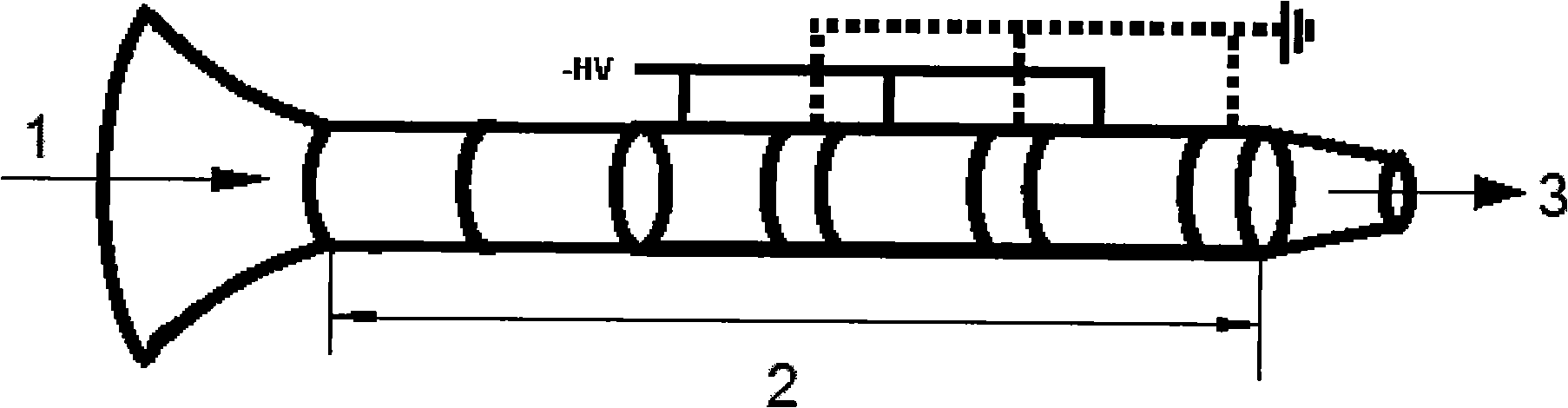

Device for exciting high-speed and large-area ionic wind

An excitation device and ion wind technology, applied in corona discharge devices, electrical components, circuits, etc., can solve the problems of low speed and small action area of ion wind excitation devices, and achieve the effects of reducing resistance, facilitating accumulation, and stabilizing discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

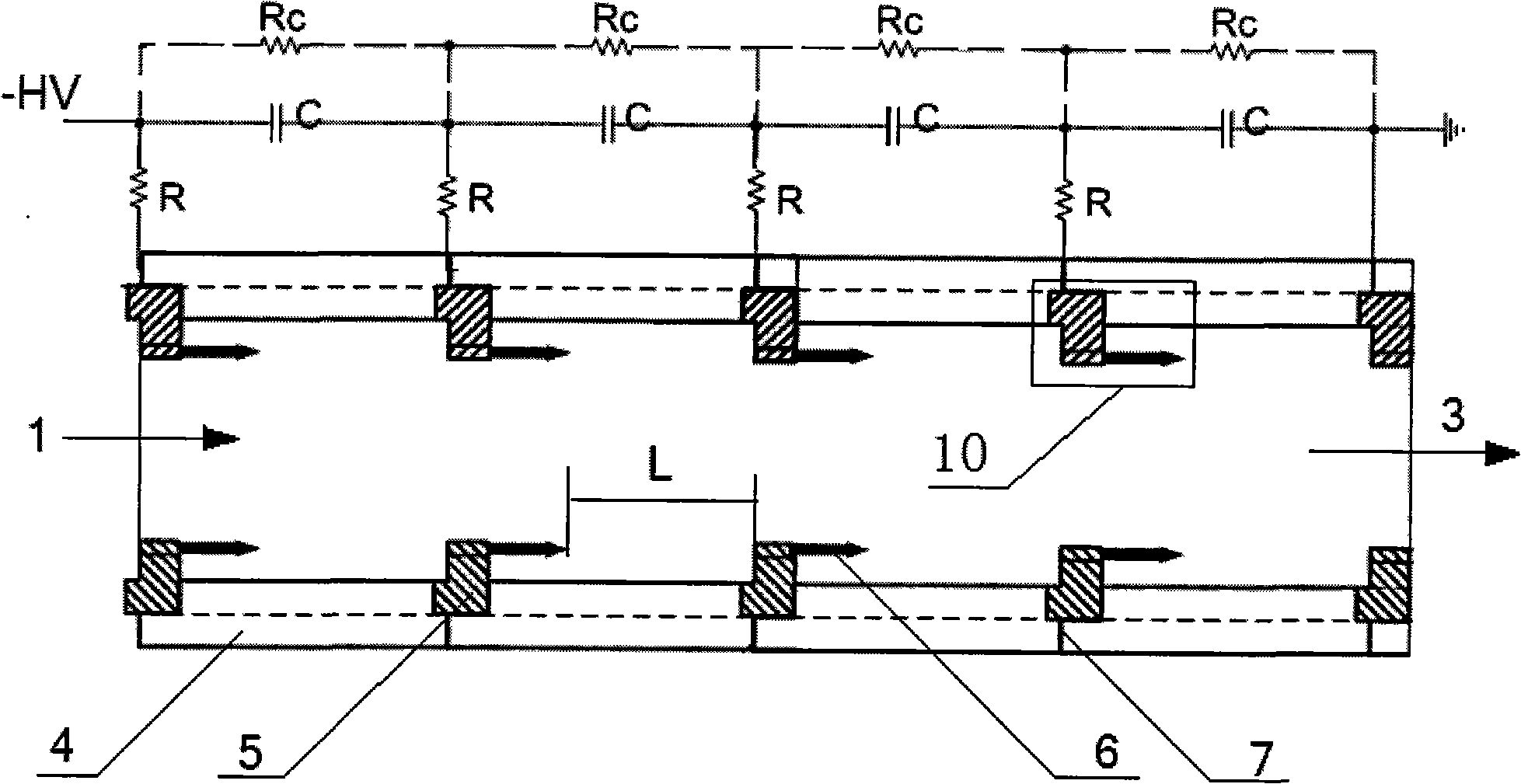

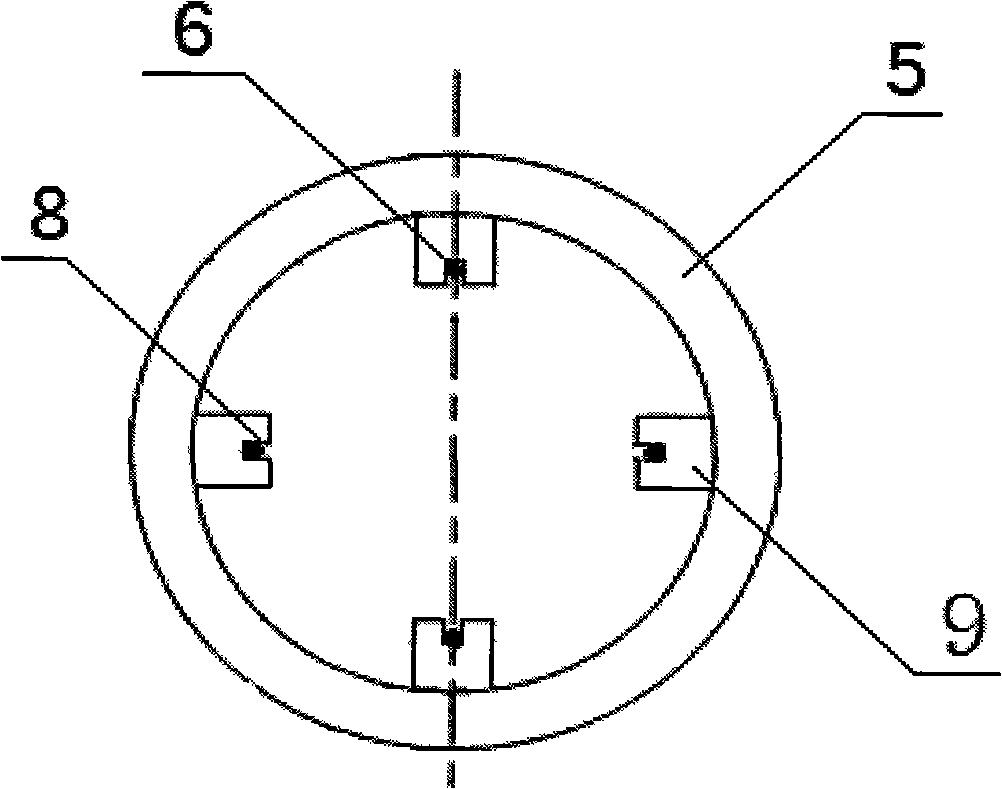

[0024] Such as figure 2 , image 3 As shown, a kind of cascaded multi-needle-ring electrode ion wind excitation device for generating high-speed, large-area ion wind of the present invention, four multi-needle ring electrodes 10 and one ring electrode 5 are embedded with an inner diameter of 19mm, and the wall Thickness is 5mm, and length is in the plexiglass barrel 4 of 21mm. The needle electrodes 6 used are all steel needles with a tip diameter of about 50 μm, which are made of ordinary steel needles by electrochemical corrosion. The material of the ring electrode 5 is brass, and four cylinders 9 with a height of 3 mm (uniformly distributed along the circumference) are processed inside, and a groove 8 with a width of 0.8 mm and a depth of 1 mm is left at the top for installation. Needle electrode 6. The multi-needle ring electrode 10 is integrated by the needle electrode 6 of the original rear stage and the ring electrode 5 of the previous stage, which fully utilizes the...

Embodiment 2

[0029] Such as figure 2 , image 3 As shown, another cascaded multi-needle ring electrode ion wind excitation device for generating high-speed, large-area ion wind of the present invention, six multi-needle ring electrodes 10 and one ring electrode 5 are embedded with an inner diameter of 19mm, and the wall Thickness is 5mm, and length is in the plexiglass barrel 4 of 16mm. The needle electrode 6 used is made of corrosion-resistant silicon crystal material by laser etching, and its tip diameter is about 5 μm.

[0030] The ring electrode 5 of each two-stage multi-needle ring electrode is connected in series with the current-limiting resistor R through a conductor 7, and then connected in parallel with a voltage dividing capacitor C to form six series voltage dividing devices, which are connected to the ring electrode near the entrance. The voltage dividing capacitor C is connected to the DC high voltage source -HV, and the voltage dividing capacitor C connected to the electr...

Embodiment 3

[0033] Such as figure 2 , Figure 4As shown, another cascaded multi-needle ring electrode ion wind excitation device for generating high-speed, large-area ion wind of the present invention, six multi-needle ring electrodes 10 and one ring electrode 5 are embedded with an inner diameter of 45mm, and the wall Thickness is 5mm, and length is in the plexiglass barrel 4 of 16mm. The needle electrode 6 used is made of corrosion-resistant silicon crystal material by laser etching, and its tip diameter is about 5 μm.

[0034] The ring electrode 5 is made of brass, and 8 cylinders 9 with a height of 3 mm (uniformly distributed along the circumference) are processed inside, and a groove 8 with a width of 0.6 mm and a depth of 1 mm is left at the top for installation. Needle electrode 6. Enlarging the inner diameter of the plexiglass tube and the number of needle electrodes 6 at each stage can increase the action range of the ion wind and control the fluid flow.

[0035] The ring el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com