A kind of gladiolus Burkholder strain and its fermentative method for producing alkaline lipase

A technology of Holder's bacteria and lipase, which is applied in the field of Burkholder's strain and its fermentation to produce alkaline lipase, can solve the problems of limited lipase activity and stability, achieve low production cost, increase yield, The effect of stabilizing enzyme production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Screening and identification of alkaline lipase-producing strains

[0033] 1. Preparation of Oriented Screening Plates

[0034] According to the characteristics that Burkholderia can use special metabolites and resistance to antibiotics, an improved TB-T plate is designed for directional screening, and the positive rate of screening Burkholderia can be as high as 100%. The detailed formula is as follows: 1L modified TB-T directional screening plate contains 2g of glucose, 0.5g of L-asparagine, NaHCO 3 0.5g, KH 2 PO 4 0.25g, MgSO 4 ·7H 2 O 0.05g, trypan blue 0.05g, tetracycline 0.01g, ampicillin 0.15g, agar powder 15g.

[0035] 2. Preparation of Identification Plates

[0036] A 1 L rhodamine B identification plate contains 5 g of peptone, 3 g of yeast extract, 8 g of NaCl, 4 mL of rhodamine B solution (0.1%, W / V), and 10 mL of soybean oil emulsion.

[0037] The preparation method of the soybean oil emulsion is as follows: 3mL soybean oil and 9mL polyvin...

Embodiment 2

[0049] Embodiment 2: Utilize BPS-1 bacterial strain and optimize medium fermentation to produce lipase

[0050] (1) Seed culture: After the BPS-1 strain is activated, it is inoculated in liquid LB medium, and cultivated at 30-35°C for 12-18 hours to obtain a seed culture solution;

[0051] (2) Fermentation culture: inoculate the seed liquid into the initial fermentation medium (as described in Example 1) by the amount of 1-1.5% (V / V), after continuous cultivation for 72 hours, 8000r / mim, centrifugal 10min, measure lipase activity.

[0052] The carbon source (glucose, sucrose, molasses, dextrin, maltose, malt extract, starch) and nitrogen source (peptone, yeast extract, corn steep liquor, urea, NaNO) of the fermentation medium were studied by single factor replacement method. 3 , NH 4 SO 4 ) and inducers (olive oil, palm oil, corn oil, soybean oil, rice bran oil, castor oil, rapeseed oil) on the production of enzymes, the optimized components were molasses 1.0% (v / v), Palm ...

Embodiment 3

[0053] Embodiment 3: the purification of alkaline lipase

[0054] 1. The optimized fermentation broth described in Example 2 is precipitated with ethanol with a final concentration of 60% (v / v), centrifuged at 8000r / mim for 10min to remove foreign proteins, and then the final concentration is 95% (v / v) The target protein was precipitated with ethanol, and the obtained precipitate was collected after centrifugation at 8000 r / mim for 10 min, and dissolved in 0.05 mol / L piperazine buffer solution with a pH value of 9.7 to obtain a preliminary purified enzyme solution.

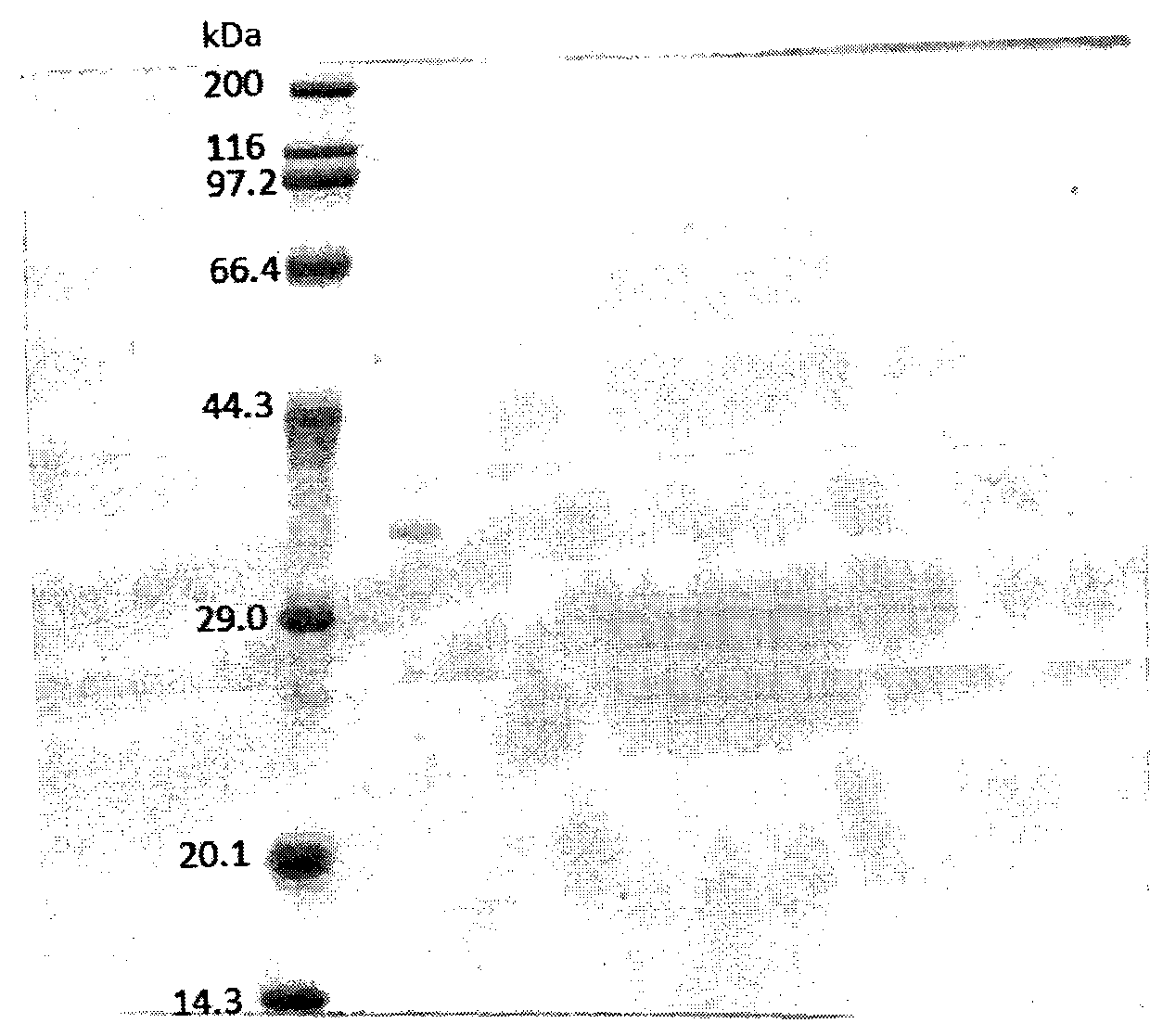

[0055] 2. The initially purified enzyme solution was subjected to HiTrap Q ion exchange chromatography and superdex 75 gel filtration chromatography, and further purified to obtain electrophoretic pure lipase protein (such as figure 1 Shown), the molecular weight of this lipase is about 35kDa, and the lipase specific activity after purification is 443904.8U / mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com