Hemicellulase and its application in preparing chitoligose

A technology of hemicellulase and hemicellulase, applied in the direction of hydrolytic enzymes, etc., can solve the problems of long enzymatic hydrolysis time, low enzymatic activity of chitosan enzyme, high energy consumption, etc., and achieve the effect of improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

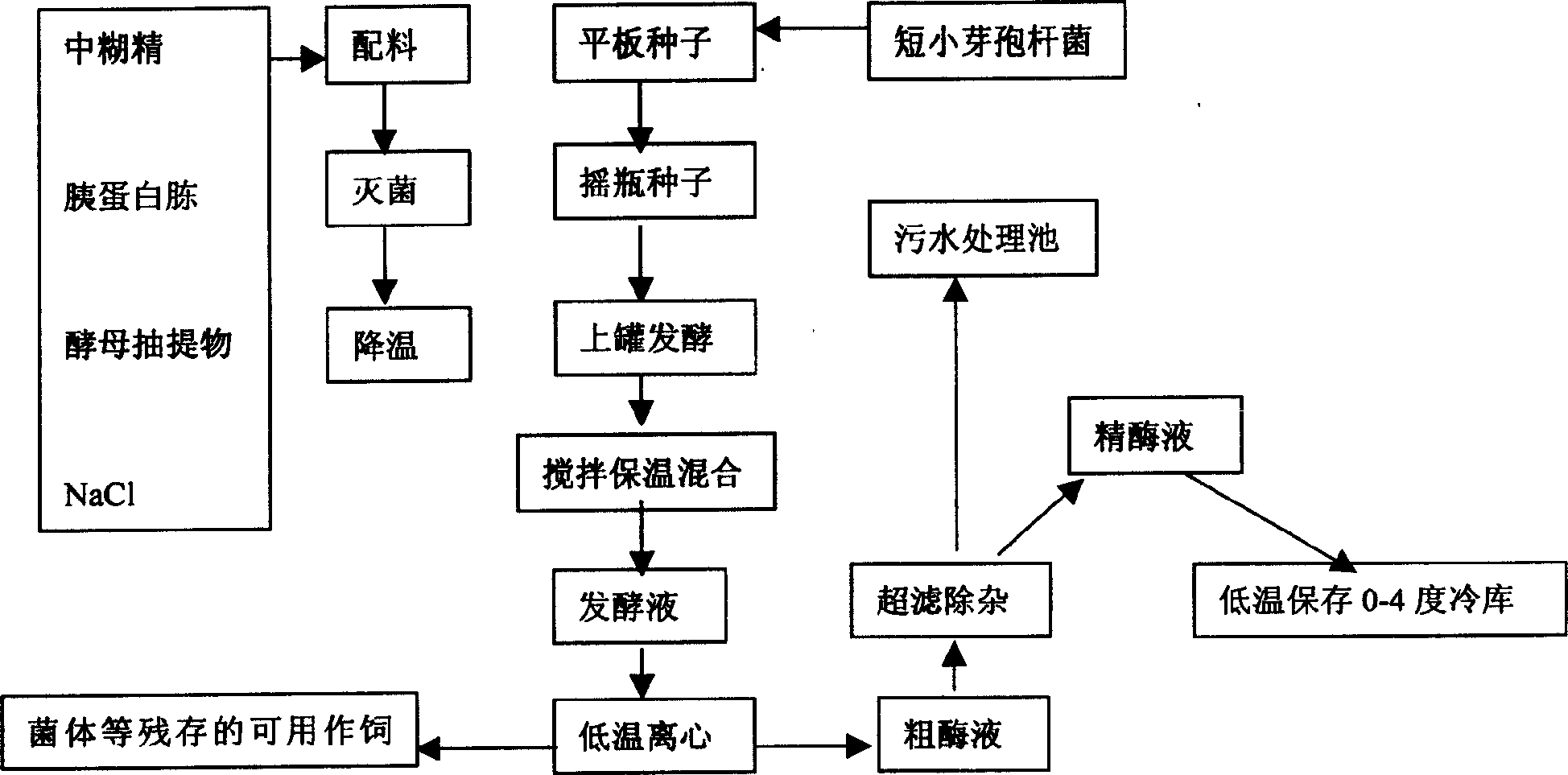

[0049] Embodiment 1: the preparation of hemicellulase of the present invention

[0050] 1. Inoculate the Hemicellulase A1 strain by streaking method on the plate medium containing Tryptone (Tryptone) 1% yeast extract (Yeast extract) 0.5% sodium chloride (Nacl) 1% and agar 1% , used after culturing at 37°C for 18 hours;

[0051] 2. Use a 1000ml Erlenmeyer shaker flask to pack 100ml of liquid medium containing 10% dextrin, tryptone (Tryptone) 1% yeast extract (Yeast extract) 0.5% Nacl 1%, sterilize on 10 pounds for 20 minutes, and inoculate a Ring, shake (250r / min) on a shaker at 36°C for 18 hours;

[0052] 3. Put 8 liters of liquid medium containing medium dextrin, tryptone, and yeast extract in a 10 liter fermenter, sterilize as above, then connect 100 ml of shake flask seed suspension, and cultivate with aeration and stirring at 36° C. for 24 hours.

[0053] 4. Low-temperature centrifugal separation of enzyme liquid: put the fermentation liquid into the centrifuge barrel of...

Embodiment 2

[0054] Embodiment 2: Utilize hemicellulase provided by the invention to produce chitosan oligosaccharide

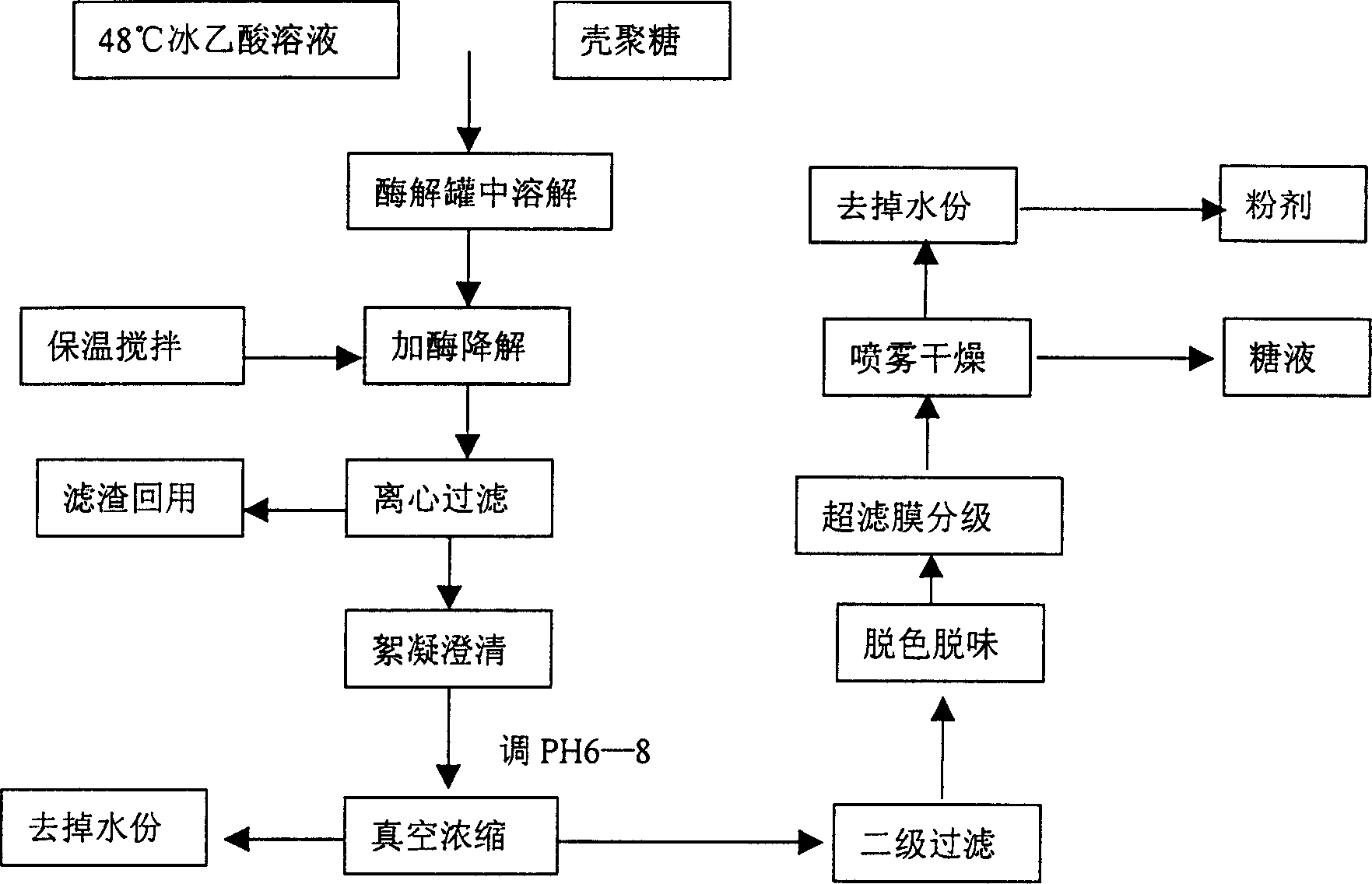

[0055] 1. Process flow: chitosan glacial acetic acid solution → tank enzymatic hydrolysis → centrifugation, flocculation, filtration to remove impurities → decolorization, deodorization → ultrafiltration classification → vacuum concentration → spray drying → chitosan oligosaccharides

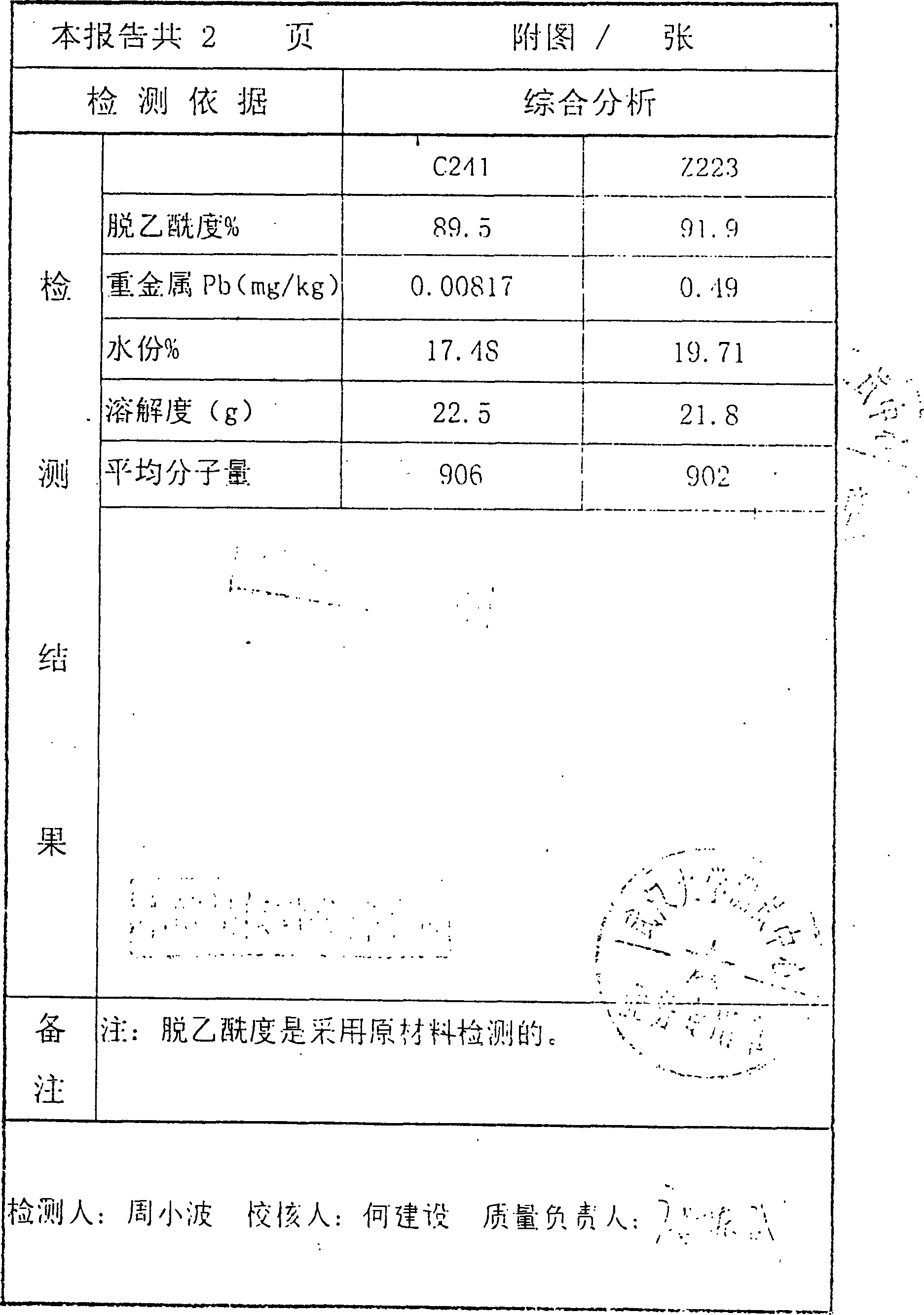

[0056] 2. Operating procedures: (1) enzymatic hydrolysis process glacial acetic acid is prepared into a 2% solution, add chitosan and heat up and stir to dissolve, the temperature is controlled at 48°C, the volume-to-weight ratio of chitosan and glacial acetic acid solution (W / V ) is 10%. Add the hemicellulose enzymatic solution of the present invention for degradation, the reaction temperature is 48°C-50°C, heat preservation, stirring, time 8 hours; (2) Centrifugal filtration Centrifugal filtration of the reacted enzymolysis solution, rotating speed 3000r / min, time 15 Minutes; (3) floccul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com