Preparation method for coating film capable of enhancing hardness and toughness of soft package lithium battery

A soft-pack lithium battery and coating technology, which is applied in coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problem that the hardness and toughness of the battery cannot be improved, the hardness and toughness of the aluminum-plastic film are not enough, and the aluminum-plastic film is easily damaged And other problems, to achieve excellent chemical stability and strong adhesion, low raw material cost, low water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

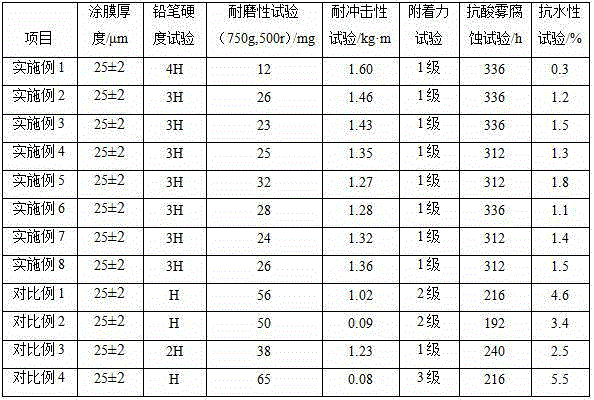

Examples

Embodiment 1

[0023] Embodiment 1, the preparation method of the coating film of the present invention to enhance the hardness and toughness of soft-pack lithium batteries

[0024] (1) Preparation of coating solution: Stir the solvent at a stirring speed of 1000rpm for 5 minutes, then add a composition of acrylic modified alkyd resin, phenolic modified epoxy resin and polyether ether ketone with a weight of 0.25% of the solvent, and heat Stir at 60°C for 30 minutes, then add polydimethylsiloxane with 1% by weight of solvent and polyether polyester modified organosiloxane with 1.5% by weight of solvent; stop heating, continue to add solvent to adjust the viscosity of the system to 5000cps , and then stirred for 20min to obtain a coating solution;

[0025] Described solvent is the mixture of acetone and butyl acetate, and the weight ratio of described acetone and butyl acetate is 10:1;

[0026] The weight ratio of the acrylic modified alkyd resin, phenolic modified epoxy resin and polyether...

Embodiment 2

[0028] Embodiment 2, the preparation method of the coating film of the present invention to enhance the hardness and toughness of soft-pack lithium batteries

[0029] (1) Preparation of coating solution: Stir the solvent for 4 minutes at a stirring speed of 1500 rpm, then add a composition of rosin-modified alkyd resin, cycloaliphatic epoxy resin and polyetheretherketone at a rate of 0.2% by weight of the solvent, and heat to 55°C, stirred for 20 minutes, then added polyether modified silicone oil defoamer with a solvent weight of 1.5% and diacetone alcohol with a solvent weight of 2.0%; stopped heating, continued to add solvents to adjust the viscosity of the system to 10000cps, and then stirred for 10 minutes to obtain a coating Membrane fluid;

[0030] Described solvent is the mixture of acetone and butyl acetate, and the weight ratio of described acetone and butyl acetate is 8:1;

[0031] The weight ratio of the rosin-modified alkyd resin, alicyclic epoxy resin and poly...

Embodiment 3

[0033] Example 3, the preparation method of the coating film of the present invention to enhance the hardness and toughness of soft-pack lithium batteries

[0034] (1) Preparation of coating solution: Stir the solvent at a stirring speed of 800 rpm for 6 minutes, then add a composition of acrylic modified alkyd resin, bisphenol A epoxy resin and polyether ether ketone at 0.3% by weight of the solvent, Heat to 65°C, stir for 40 minutes, then add polyether defoamer with 1% solvent weight and acrylic resin with 2.0% solvent weight; stop heating, continue to add solvent to adjust the viscosity of the system to 3000cps, and then stir for 30 minutes to obtain a coating solution;

[0035] Described solvent is the mixture of acetone and butyl acetate, and the weight ratio of described acetone and butyl acetate is 12:1;

[0036] The weight ratio of the acrylic modified alkyd resin, bisphenol A epoxy resin and polyether ether ketone is 1:1:0.2.

[0037] (2) Preparation of coating fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com