Probiotics microcapsule and preparation method thereof

A probiotics and microcapsule technology, applied in food preparation, bacteria, lactobacilli and other directions used in food preparation, can solve the problems of large particle size, large degree of adhesion of microcapsules, poor dispersibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

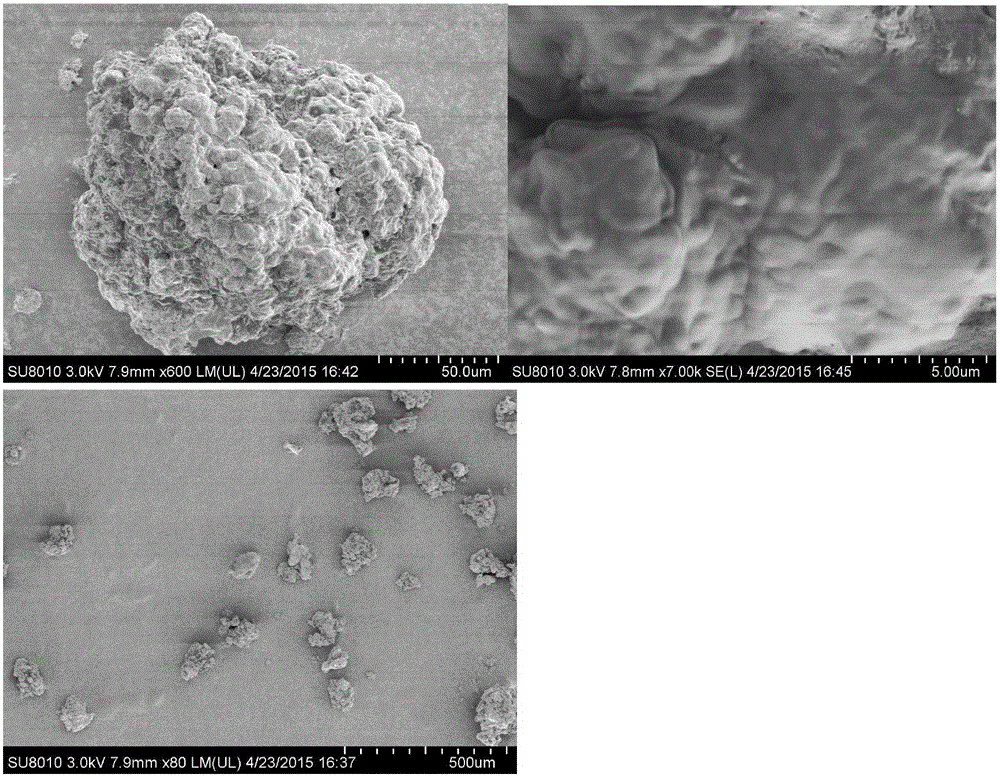

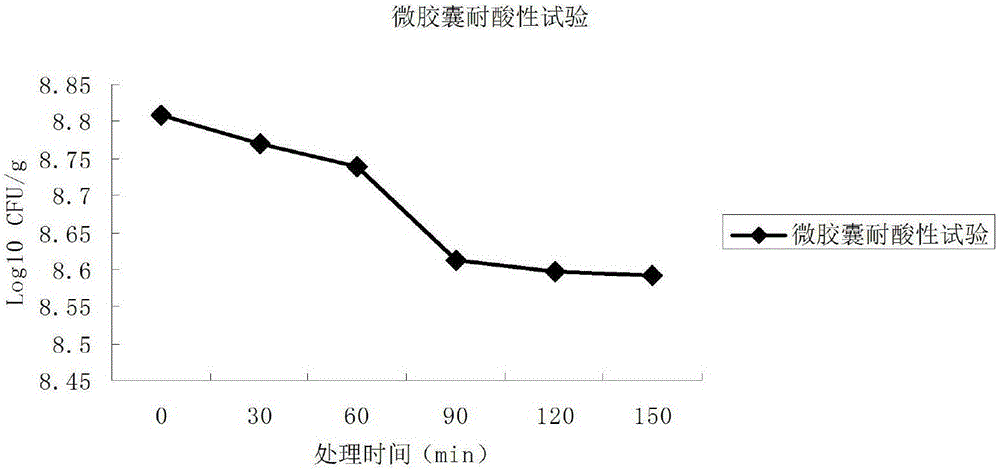

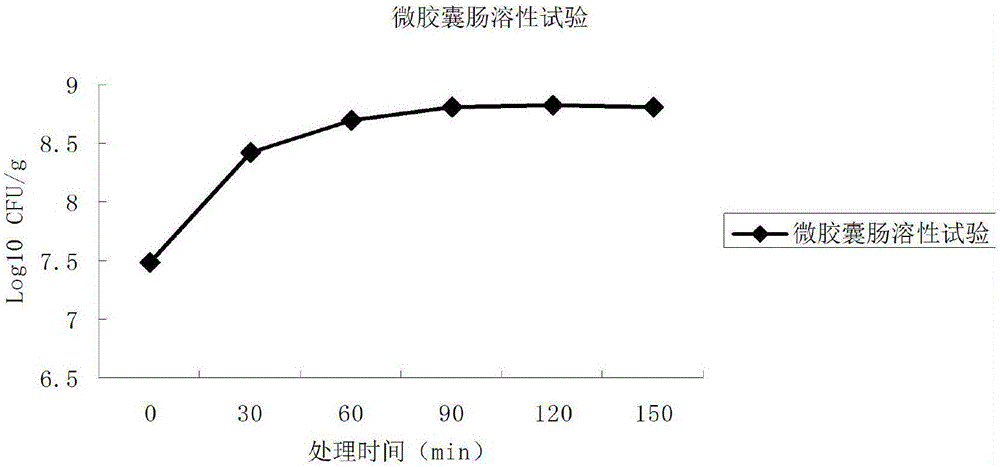

[0105] Embodiment 1: Preparation of probiotic microcapsules of the present invention

[0106] The implementation steps of this embodiment are as follows:

[0107] A. Strain activation

[0108] The Lactobacillus plantarum LIP-1 probiotic obtained from the Key Laboratory of Dairy Biotechnology and Engineering of the Ministry of Education of Inner Mongolia Agricultural University was inoculated into the MRS liquid medium sold by Oxoid under the trade name MRSBroth, and activated at a temperature of 37°C. 17 hours for activation and culture for three generations, and then use a centrifugal device to perform centrifugation at a speed of 3000r / min for 12 minutes to collect the sludge. According to the weight ratio of the sludge to saline 1:3, the concentration of the sludge is Wash with 15% sterile saline by mass for 3 times, then resuspend in sterile water, and mix well to obtain a probiotic with a density of 1.1×10 9 The concentrated bacterial solution of cfu / mL was then poured ...

Embodiment 2

[0118] Embodiment 2: Preparation of probiotic microcapsules of the present invention

[0119] The implementation steps of this embodiment are as follows:

[0120] A. Strain activation

[0121] Lactobacillus casei ZHANG probiotics obtained from the Key Laboratory of Dairy Biotechnology and Engineering of the Ministry of Education of Inner Mongolia Agricultural University were inoculated into MRS liquid medium sold by Oxoid under the trade name MRSBroth, and activated and cultivated at a temperature of 37°C for 16 hours Carry out activation and culture for three generations, and then use a centrifugal device to perform centrifugation at a speed of 3300r / min for 10 minutes to collect the sludge. According to the weight ratio of the sludge to normal saline 1:4, the concentration of the sludge to be used again is by mass Washed twice with 30% sterilized normal saline, then resuspended in sterile water, and mixed evenly to obtain a probiotic with a density of 1.2×10 9 The concentr...

Embodiment 3

[0131] Embodiment 3: Preparation of probiotic microcapsules of the present invention

[0132] The implementation steps of this embodiment are as follows:

[0133] A. Strain activation

[0134] Lactobacillus plantarum P8 probiotics obtained from the Key Laboratory of Dairy Biotechnology and Engineering of the Ministry of Education of Inner Mongolia Agricultural University were inoculated into MRS liquid medium sold by Oxoid under the trade name MRSBroth, and activated and cultivated at a temperature of 37°C for 20 hours Carry out activation and culture for three generations, and then use a centrifugal device to perform centrifugation at a speed of 3700r / min for 14 minutes to collect the bacteria sludge. According to the weight ratio of the bacteria sludge to normal saline 1:6, the concentration of the bacteria sludge is calculated by mass. 20% sterilized saline was washed 3 times, then resuspended in sterile water, and mixed evenly to obtain a probiotic with a density of 1.4×1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com