High-light-transmittance UV-moisture dual-curing adhesive

A UV-, dual-curing technology, applied in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of many by-products, increased cost, complicated operation, etc., to achieve good corrosion resistance, excellent adhesion. The effect of bonding and mechanical strength, good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

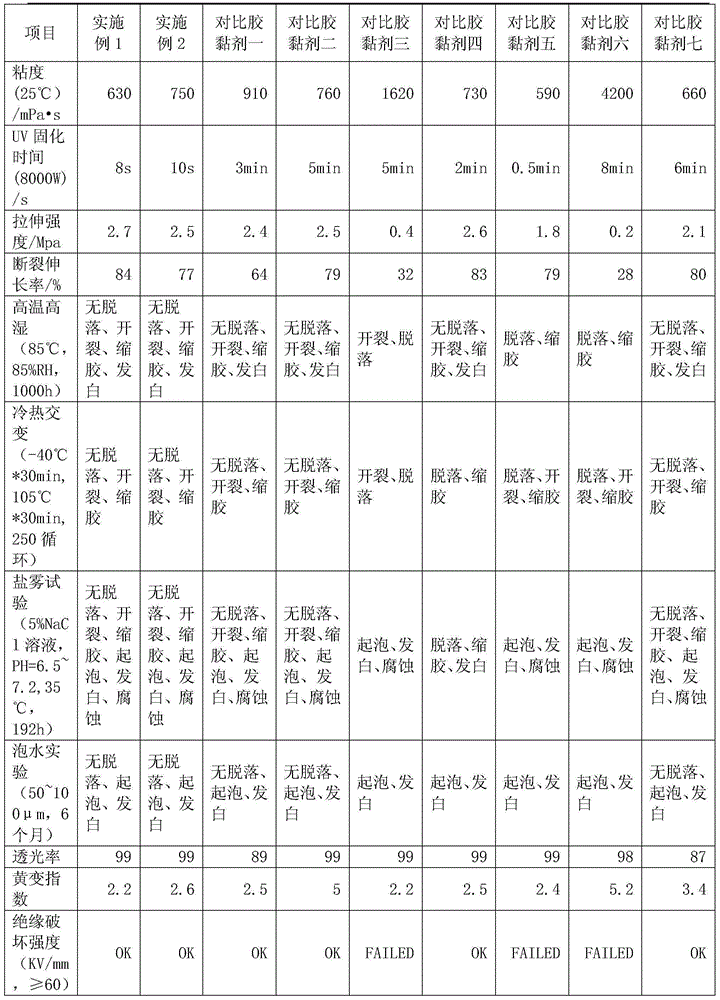

Examples

Embodiment 1

[0033] Mix hydroquinone monomethyl ether and diglycidyl phthalate evenly, heat to dissolve, raise the temperature to 85°C, add acrylic acid containing tetraethylammonium bromide dropwise, keep warm, and react until the acid value is less than 3mgKOH / g stops, and the epoxy acrylate monoester containing hydroxyl is obtained after the reaction is completed. N 2 Under a protective atmosphere, after dehydrating hexanediol, add isophorone diisocyanate containing dibutyltin dilaurate dropwise to it while stirring, heat to 60°C for 4 hours after the dropwise addition, and cool to room temperature after the reaction is completed. Obtain an isocyanate-terminated oligomer; then continue to add dropwise the prepared hydroxyl-containing epoxy acrylate monoester, after the dropwise addition, heat to 85°C for 3 hours, stop heating and lower the temperature; then carry out low-pressure distillation on the obtained product, After removing low-molecular substances, the required polyurethane p...

Embodiment 2

[0036] Mix hydroquinone monomethyl ether and diglycidyl phthalate evenly, heat to dissolve, raise the temperature to 90°C, add acrylic acid containing tetraethylammonium bromide dropwise, keep warm, and react until the acid value is less than 3mgKOH / g stops, and the epoxy acrylate monoester containing hydroxyl is obtained after the reaction is completed. N 2 Under a protective atmosphere, after dehydrating polyethylene glycol PEG-400, add isophorone diisocyanate containing dimethyltin diacetate dropwise to it while stirring, heat to 65°C for 4 hours after the dropwise addition, and the reaction is complete After cooling to room temperature, an isocyanate-terminated oligomer was obtained; then, the prepared hydroxyl-containing epoxy acrylate monoester was continued dropwise, and after the dropwise addition was completed, it was heated to 90°C for 3 hours, and the heating was stopped and the temperature was lowered; then the obtained The product is subjected to low-pressure di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com