Pervious concrete for highway engineering

A permeable concrete and engineering technology, applied in the field of building materials, can solve the problems of poor corrosion resistance to salt, high porosity, poor durability, etc., achieve good corrosion resistance and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

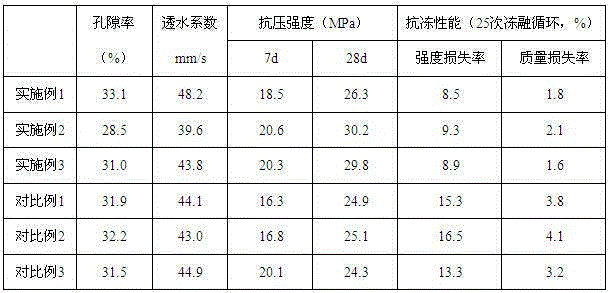

[0021] In this embodiment, the corrosion-resistant permeable concrete is composed of 20wt% P.O42.5 cement, 1.2wt% anhydrite powder, 6.0wt% slag pellets, 20wt% electric furnace steel slag, 3.2wt% admixture, and the balance of gravel. Wherein, the admixture contains: 30.0wt% silica sol, 15.0wt% alkylphenol ether sulfosuccinate, 15.0wt% lignosulfonate, 4.0wt% acrylic acid-acrylamide copolymer sodium Salt, 3.0wt% of tetramethylene diisocyanate, 2.5wt% of triglycidyl isocyanurate, 1.2wt% of triphenyl phosphite, and the balance of diethanolamine.

Embodiment 2

[0023] In this embodiment, the corrosion-resistant permeable concrete is composed of 25wt% P.O42.5 cement, 1.0wt% anhydrite powder, 5.0wt% slag pellets, 23wt% blast furnace steel slag, 3.2wt% admixture, and the balance of gravel. Wherein, the admixture contains: 30.0wt% silica sol, 15.0wt% alkylphenol ether sulfosuccinate, 15.0wt% lignosulfonate, 4.0wt% acrylic acid-acrylamide copolymer sodium Salt, 3.0wt% of tetramethylene diisocyanate, 2.5wt% of triglycidyl isocyanurate, 1.2wt% of triphenyl phosphite, and the balance of diethanolamine.

Embodiment 3

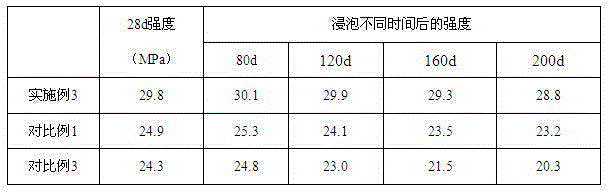

[0025] In this embodiment, the corrosion-resistant permeable concrete is composed of 22wt% P.O42.5 cement, 1.2wt% anhydrite powder, 5.5wt% slag pellets, 23wt% electric furnace steel slag, 3.0wt% admixture, and the balance of gravel. Wherein, the admixture contains: 28.0wt% silica sol, 18.0wt% alkylphenol ether sulfosuccinate, 12.0wt% lignosulfonate, 4.0wt% acrylic acid-acrylamide copolymer sodium Salt, 4.0wt% tetramethylene diisocyanate, 2.3wt% triglycidyl isocyanurate, 1.2wt% triphenyl phosphite, and the balance of diisopropanolamine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com