A water-based liquid reinforcing material for high-performance water-permeable concrete and a preparation method thereof

A permeable concrete and water-based liquid technology, which is applied in the field of permeable concrete additives, can solve problems such as high cost, secondary pollution, and falling stones, achieve early strength and later durability, avoid secondary water addition, and improve bond strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

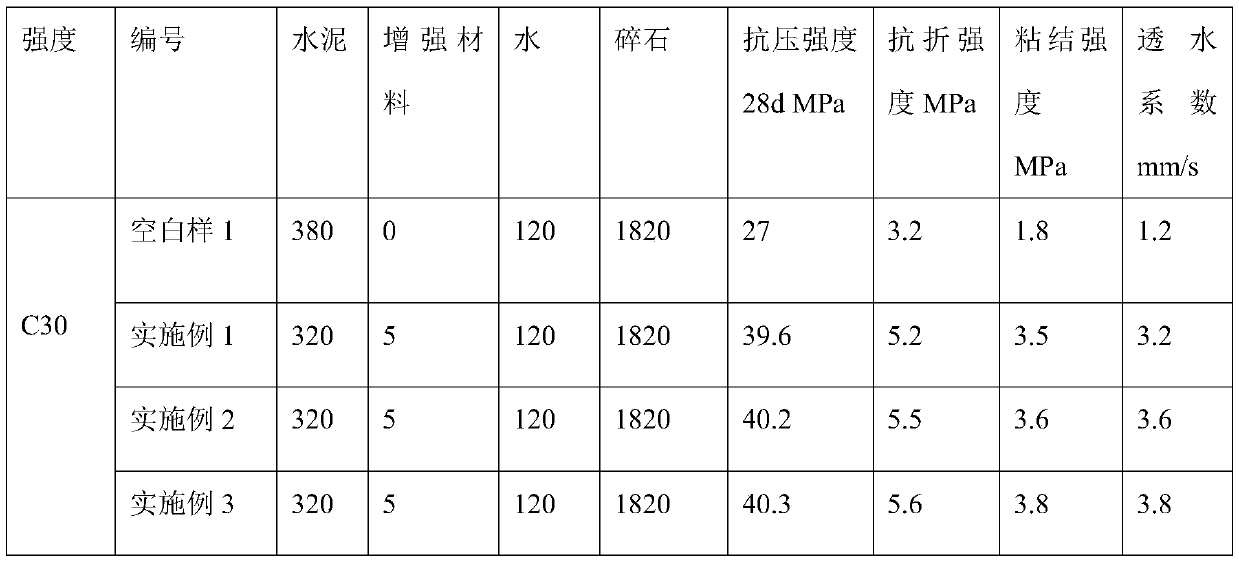

Embodiment 1

[0047] The technical solution adopted in the present invention is: a high-performance permeable concrete water-based liquid reinforcing material, which is composed of the following raw materials in parts by weight:

[0048] 5 parts of powder reinforced polymer, 40 parts of nano-silica fume, 10 parts of water reducer, 3 parts of viscosity modifier, 1 part of defoamer, 0.5 part of retarder, 0.5 part of rheological agent and 10 parts of early strength agent.

[0049] In this example,

[0050] The powder reinforced polymer is epoxy resin powder;

[0051] SiO2 content in micro silicon powder is 92%;

[0052] The water reducing agent is a polycarboxylate high-efficiency water reducing agent with a water reducing rate of 35%;

[0053] The retarder is compounded by 70wt% industrial grade powdered sodium pyrophosphate and 30wt% industrial grade sodium phosphate;

[0054] Viscosity modifier is industrial grade carboxymethyl cellulose;

[0055] Defoamer is polysiloxane defoamer;

[...

Embodiment 2

[0063] The technical solution adopted in the present invention is: a high-performance permeable concrete water-based liquid reinforcing material, which is composed of the following raw materials in parts by weight:

[0064] 12 parts of powder reinforced polymer, 50 parts of nano-silica fume, 14 parts of water reducer, 5 parts of viscosity modifier, 1 part of defoamer, 0.8 part of retarder, 0.6 part of rheological agent and 12 parts of early strength agent.

[0065] In this example,

[0066] The powder reinforced polymer is acrylate powder;

[0067] The content of SiO2 in micro-silicon powder is 92%;

[0068] The water reducing agent is a naphthalene-based high-efficiency water reducing agent with a water reducing rate of 35%;

[0069] Retarder is 70wt% industrial grade powdery sodium pyrophosphate;

[0070] Viscosity modifier is industrial grade carboxyethyl cellulose;

[0071] Defoamer is polysiloxane defoamer;

[0072] The early strength agent is Glauber's salt;

[007...

Embodiment 3

[0079] The technical solution adopted in the present invention is: a high-performance permeable concrete water-based liquid reinforcing material, which is composed of the following raw materials in parts by weight:

[0080] 20 parts of powder reinforced polymer, 50 parts of nano-silica fume, 15 parts of water reducer, 5 parts of viscosity regulator, 1 part of defoamer, 0.5 part of retarder, 0.6 part of rheological agent and 15 parts of early strength agent.

[0081] In this example,

[0082] The powder reinforced polymer is modified polyester powder;

[0083] The content of SiO2 in micro-silicon powder is 92%;

[0084] The water reducing agent is a polycarboxylate high-efficiency water reducing agent with a water reducing rate of 35%;

[0085] Retarder is 70wt% industrial grade powdery sodium pyrophosphate;

[0086] Viscosity modifier is industrial grade carboxyethyl cellulose;

[0087] Defoamer is polysiloxane defoamer;

[0088] The early strengthening agent is sodium ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com