Water-permeable brick and method for preparing sintered water-permeable brick from manganese dioxide slag and plant ash

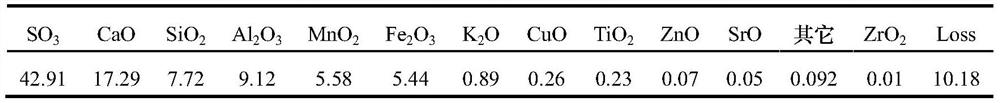

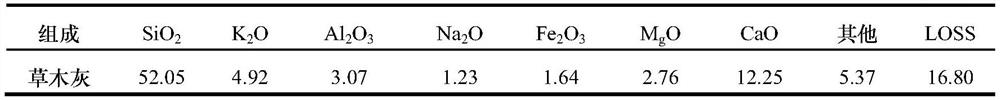

A technology of manganese dioxide slag and electrolytic manganese dioxide, which is applied in applications, household utensils, clay products, etc., can solve the problems of single utilization method and the difficulty of recycling electrolytic manganese dioxide waste slag, and achieve ideal comprehensive performance and high water permeability Coefficient, the effect of ensuring compressive strength and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

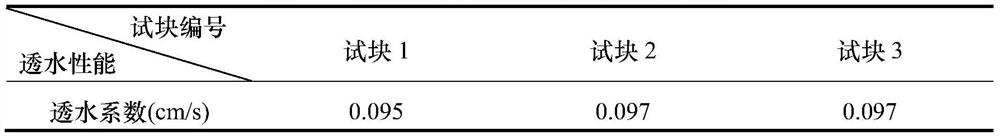

Embodiment 1

[0029] The raw material components used in this embodiment include water by the following powder raw materials in parts by weight: 52 parts of electrolytic manganese dioxide slag passing through a 200 mesh sieve, 25 parts of plant ash, 20 parts of 800 mesh quartz powder, 2.5 parts of sodium silicate, 18 parts of limestone powder with a fineness of 0.3mm.

[0030] The steps for preparing sintered permeable bricks are:

[0031] 1. Preparation of green body wet material: Dissolve sodium silicate with an appropriate amount of water at 40-50°C, dry-type stir and mix other powder materials evenly, and then add sodium silicate aqueous solution and water to stir. The water consumption in this step is 29wt% of the total amount of powder, after stirring to obtain fine sandy non-cohesive wet ash particles, stop stirring to obtain wet powder;

[0032] 2. Wet material compression molding: add wet powder into the molding mold three times, and tamp it after each feeding. After all the wet p...

Embodiment 2

[0044] The raw material components used in this embodiment include water by the following powder raw materials in parts by weight: 56 parts of electrolytic manganese dioxide slag, 23 parts of plant ash, 24 parts of quartz powder, 3 parts of sodium silicate, and 22 parts of fineness of 0.3mm of limestone powder.

[0045] The steps for preparing sintered permeable bricks are:

[0046] 1. Preparation of green body wet material: Dissolve sodium silicate with an appropriate amount of water at 40-50°C, dry-type stir and mix other powder materials evenly, and then add sodium silicate aqueous solution and water to stir. The water consumption in this step is 31wt% of the powder total amount, after stirring to obtain fine sandy non-cohesive wet ash particles, stop stirring to obtain wet powder;

[0047] 2. Wet material compression molding: add wet powder into the molding mold three times, tamp it after each feeding, after all the wet powder is added, mold compression molding, molding p...

Embodiment 3

[0058] The raw material components used in this embodiment include water by the following powder raw materials in parts by weight: 54 parts of electrolytic manganese dioxide slag, 20 parts of plant ash, 22 parts of quartz powder, 2.8 parts of sodium silicate, and 20 parts of fineness of 0.3mm of limestone powder.

[0059] The steps for preparing sintered permeable bricks are:

[0060] 1. Preparation of green body wet material: Dissolve sodium silicate with an appropriate amount of water at 40-50°C, dry-type stir and mix other powder materials evenly, and then add sodium silicate aqueous solution and water to stir. The water consumption in this step is 30wt% of the total amount of powder, after stirring to obtain fine sandy non-cohesive wet ash particles, stop stirring to obtain wet powder;

[0061] 2. Wet material compression molding: add wet powder into the molding mold three times, tamp it after each feeding, after all the wet powder is added, mold compression molding, mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com