A special recycled modified material for solid wall pipes and its preparation method and application

A technology of regenerating modified materials and solid-wall pipes, which is applied in the field of organic polymer materials, can solve the problems of no such pipes, achieve the effects of improving ring stiffness, reducing large consumption, and increasing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

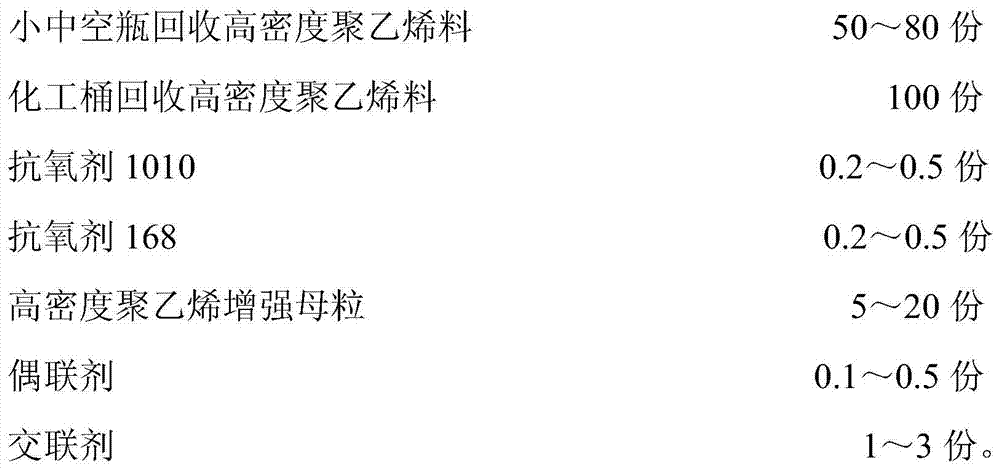

Embodiment 1

[0040]50 parts of recycled high-density polyethylene materials in small hollow bottles, and 100 parts of recycled high-density polyethylene materials in chemical barrels are added together in the mixer and mixed for 60 minutes, and the extruder on the single-screw (the temperature setting of the extruder on the single-screw) 200°C, with 2 exhaust ports on it) to obtain a molten mixture; 0.2 parts of 1010 antioxidant, 0.2 parts of 168 antioxidant, 5 parts of high-density polyethylene reinforced masterbatch, coupling agent 0.1 part of titanate coupling agent JTW-101 (purchased from Nanjing Jingtianwei Chemical Co., Ltd.), 1 part of crosslinking agent dicumyl peroxide (purchased from AkzoNobel Peroxide Ningbo Co., Ltd.), add together In a high-speed mixer, mix for 2 minutes at a speed of 600r / min and a temperature of 80°C to obtain a uniformly dispersed additive mixture; the molten mixture and additive mixture obtained in the above steps are simultaneously fed into the twin-screw ...

Embodiment 2

[0043] 50 parts of recycled high-density polyethylene materials in small hollow bottles, and 100 parts of recycled high-density polyethylene materials in chemical barrels are added together in the mixer and mixed for 60 minutes, and the extruder on the single-screw (the temperature setting of the extruder on the single-screw) 220°C, with 3 vents on it) to melt and extrude to obtain a molten mixture; 0.2 parts of 1010 antioxidant, 0.2 parts of 168 antioxidant, 5 parts of high-density polyethylene reinforced masterbatch, coupling agent 0.1 part of titanate coupling agent JTW-101 (purchased from Nanjing Jingtianwei Chemical Co., Ltd.), 1 part of crosslinking agent dicumyl peroxide (purchased from AkzoNobel Peroxide Ningbo Co., Ltd.), add together In a high-speed mixer, mix for 2 minutes at a speed of 600r / min and a temperature of 80°C to obtain a uniformly dispersed additive mixture; the molten mixture and additive mixture obtained in the above steps are simultaneously fed into th...

Embodiment 3

[0046] 80 parts of recycled high-density polyethylene materials in small hollow bottles and 100 parts of recycled high-density polyethylene materials in chemical barrels were added to the mixer and mixed for 60 minutes. 180°C, with 2 exhaust ports on it) to obtain a molten mixture; 0.5 parts of 1010 antioxidant, 0.5 parts of 168 antioxidant, 20 parts of high-density polyethylene reinforced masterbatch, coupling agent Add 0.5 parts of titanate coupling agent JTW-101 (purchased from Nanjing Jingtianwei Chemical Co., Ltd.), and 3 parts of crosslinking agent dicumyl peroxide (purchased from AkzoNobel Peroxide Ningbo Co., Ltd.) In a high-speed mixer, mix for 2 minutes at a speed of 600r / min and a temperature of 80°C to obtain a uniformly dispersed additive mixture; the molten mixture and additive mixture obtained in the above steps are simultaneously fed into the twin-screw down extrusion Extruder (the temperature of the twin-screw lower extruder is set to 200°C, and the screw leng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com