Polypropylene/polystyrene alloy and preparation method thereof

A polystyrene and polypropylene technology, applied in the field of polypropylene/polystyrene alloy and its preparation, can solve the problems of many side reactions and complex process, and achieve improved compatibility, simple process and increased free volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

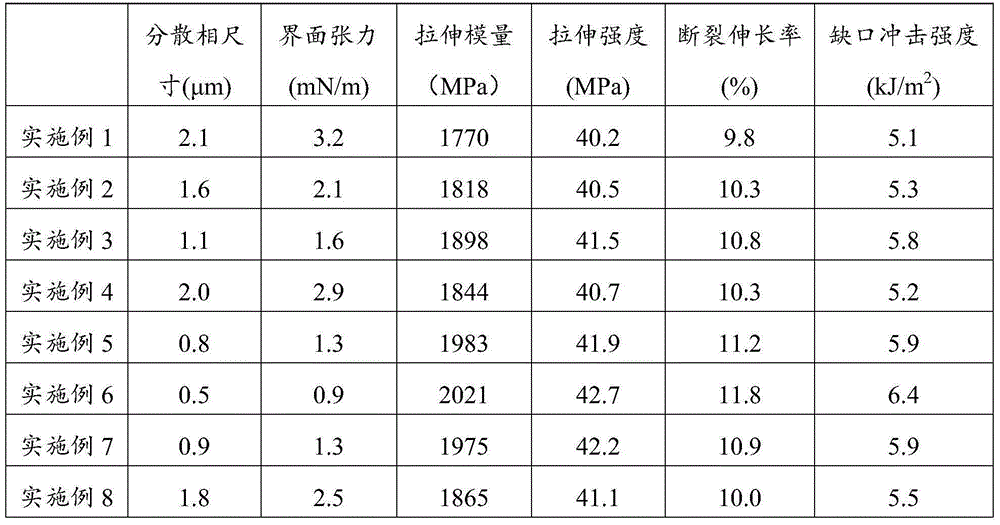

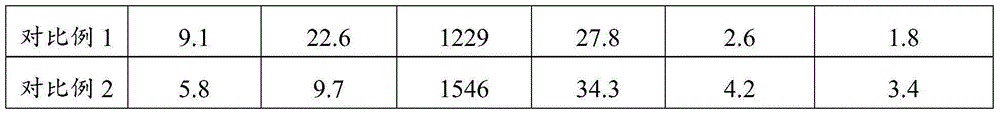

Examples

preparation example Construction

[0020] The invention provides a kind of preparation method of polypropylene / polystyrene alloy, it comprises the steps:

[0021] a Weigh 50-90 parts by weight of polypropylene, 10-50 parts by weight of polystyrene, 1-5 parts by weight of acrylate monomer with multifunctional groups, 0.1-0.5 parts by weight of antioxidant, and 0.01-0.5 parts by weight of initiator share;

[0022] b. Add the acrylate monomer with multifunctional groups, antioxidant and initiator into the organic solvent to premix and obtain a premixed solution, and then mix the premixed solution with polypropylene and polystyrene to obtain a mixture;

[0023] c. Put the mixture into a screw extruder, and feed supercritical carbon dioxide into 1 / 5-1 / 3 of the screw of the screw extruder, and melt and extrude to obtain a polypropylene / polystyrene alloy.

[0024] In step a, the polypropylene can be homopolypropylene, copolymerized polypropylene or a blend of the two in any proportion, and the melt index of the polyp...

Embodiment 1

[0032] Weigh 0.1 part of dibenzoyl peroxide, 0.2 part of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 3 parts of 1,6-hexanediol diacrylic acid ester;

[0033] Add dibenzoyl peroxide, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol, 1,6-hexanediol diacrylate into 5 mL of acetone and pre-mix Obtain the premixed solution, put 70 parts of polypropylene, 30 parts of polystyrene and the premixed solution into the high-speed mixer afterwards, mix 10min with the speed of 300r / min to obtain the mixture, wherein, initiator dibenzoyl peroxide and The weight ratio of acetone is 1:70;

[0034] The mixture is added to the screw extruder; wherein, the screw speed is set to 40r / min, the temperature in the first half of the screw is set to 190°C, and the temperature in the second half of the screw is set to 165°C; 5 Parts by weight of carbon dioxide in a supercritical state, the injection pressure is set to 10 MPa, and the po...

Embodiment 2

[0036] Weigh 0.08 parts of dicumyl peroxide, 0.1 parts of thiodiethylene bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] and 5 parts of trimethylolpropane Triacrylate;

[0037] Add dicumyl peroxide, thiodiethylenebis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate] and trimethylolpropane triacrylate into 3 mL of ethanol Pre-mixed to obtain a pre-mixed solution, then put 70 parts of polypropylene, 30 parts of polystyrene and the pre-mixed solution into a high-speed mixer, and mixed at a speed of 300r / min for 10 minutes to obtain a mixture, wherein the initiator diisopropyl peroxide The weight ratio of benzene to ethanol is 1:60;

[0038] The mixture is added to the screw extruder; wherein, the screw speed is set to 70r / min, the temperature in the first half of the screw is set to 205°C, and the temperature in the second half of the screw is set to 158°C; 10 Parts by weight of carbon dioxide in a supercritical state, the injection pressure is set to 14 MPa, and the polyp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com