Method for producing nanosilicon dioxide and by-product hydrochloric acid through chlorosilane waste gas

A technology of nano-silica and by-product hydrochloric acid, which is applied in the direction of silica, silicon oxide, nanotechnology, etc., can solve the problems of secondary pollution, failure of resource utilization, and low value of resource utilization, etc., and achieve reduction The cost of waste gas treatment, reducing the pressure of sewage treatment, and realizing the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

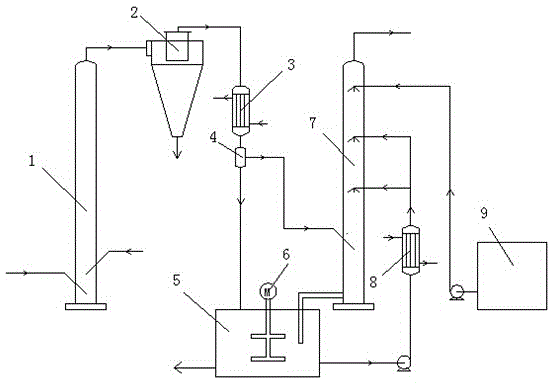

[0032] A kind of chlorosilane exhaust gas described in this embodiment produces the method for nano silicon dioxide and by-product hydrochloric acid (such as figure 1 shown), including the following steps:

[0033] (1) Gas vapor contact hydrolysis reaction: put 1000m 3 / h of chlorosilane waste gas (15% SiCl 4 , 20% SiHCl 3 , 10% SiH 2 Cl 2 , 5% HCl, 5% H 2 , 45% N 2 ) and 145m 3 / h of water vapor (temperature: 120°C pressure: 2kgf / cm 2 ) into gas-steam hydrolysis reaction tower 1 at the same time, chlorosilane waste gas is hydrolyzed in gas-steam hydrolysis reaction tower 1 filled with water vapor, and the generated silica solid enters the gas-solid separation equipment together with the air flow, and the temperature of gas-steam hydrolysis reaction tower 1 Control at 130~140°C.

[0034] (2) Gas-solid separation: Chlorosilane waste gas and water vapor hydrolysis products enter the gas-solid separator 2, the temperature of the solid-liquid separator 2 is kept at 130~14...

Embodiment 2

[0039] A kind of chlorosilane exhaust gas described in this embodiment produces the method for nano silicon dioxide and by-product hydrochloric acid (such as figure 1 shown), including the following steps:

[0040] (1) Gas vapor contact hydrolysis reaction: put 1000m 3 / h of chlorosilane waste gas (10% SiCl 4 , 30% SiHCl 3 , 15% SiH 2 Cl 2 , 5% HCl, 5% H 2 , 35% N 2 ) and 186m 3 / h of water vapor (temperature: 140°C pressure: 4kgf / cm 2 ) into gas-steam hydrolysis reaction tower 1 at the same time, chlorosilane waste gas is hydrolyzed in gas-steam hydrolysis reaction tower 1 filled with water vapor, and the generated silica solid enters the gas-solid separation equipment together with the air flow, and the temperature of gas-steam hydrolysis reaction tower 1 Control at 150~160°C.

[0041] (2) Gas-solid separation: Chlorosilane waste gas and water vapor hydrolysis products enter the gas-solid separator 2, the temperature of the solid-liquid separator 2 is kept at 150~16...

Embodiment 3

[0046] A kind of chlorosilane exhaust gas described in this embodiment produces the method for nano silicon dioxide and by-product hydrochloric acid (such as figure 1 shown), including the following steps:

[0047] (1) Gas vapor contact hydrolysis reaction: put 1000m 3 / h of chlorosilane waste gas (5% SiCl 4 , 40% SiHCl 3 , 20% SiH 2 Cl 2 , 10% HCl, 5% H 2 , 20% N 2 ) and 229m 3 / h of water vapor (temperature: 160°C pressure: 6kgf / cm 2 ) into gas-steam hydrolysis reaction tower 1 at the same time, chlorosilane waste gas is hydrolyzed in gas-steam hydrolysis reaction tower 1 filled with water vapor, and the generated silica solid enters the gas-solid separation equipment together with the air flow, and the temperature of gas-steam hydrolysis reaction tower 1 Control at 180~190°C.

[0048] (2) Gas-solid separation: Chlorosilane waste gas and water vapor hydrolysis products enter the gas-solid separator 2. The temperature of the solid-liquid separator 2 is kept at 180~19...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com