Preparation method for fiber reinforced silica aerogel oil absorbing sponge

A fiber reinforced, silicon aerogel technology, applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems of poor dispersion and compatibility of reinforcement materials, low elasticity and strength of silicon aerogel sponge, and increased processing costs. , to achieve the effect of promoting the hydrolysis and polycondensation reaction, solving the problem of low mechanical strength and reducing the probability of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

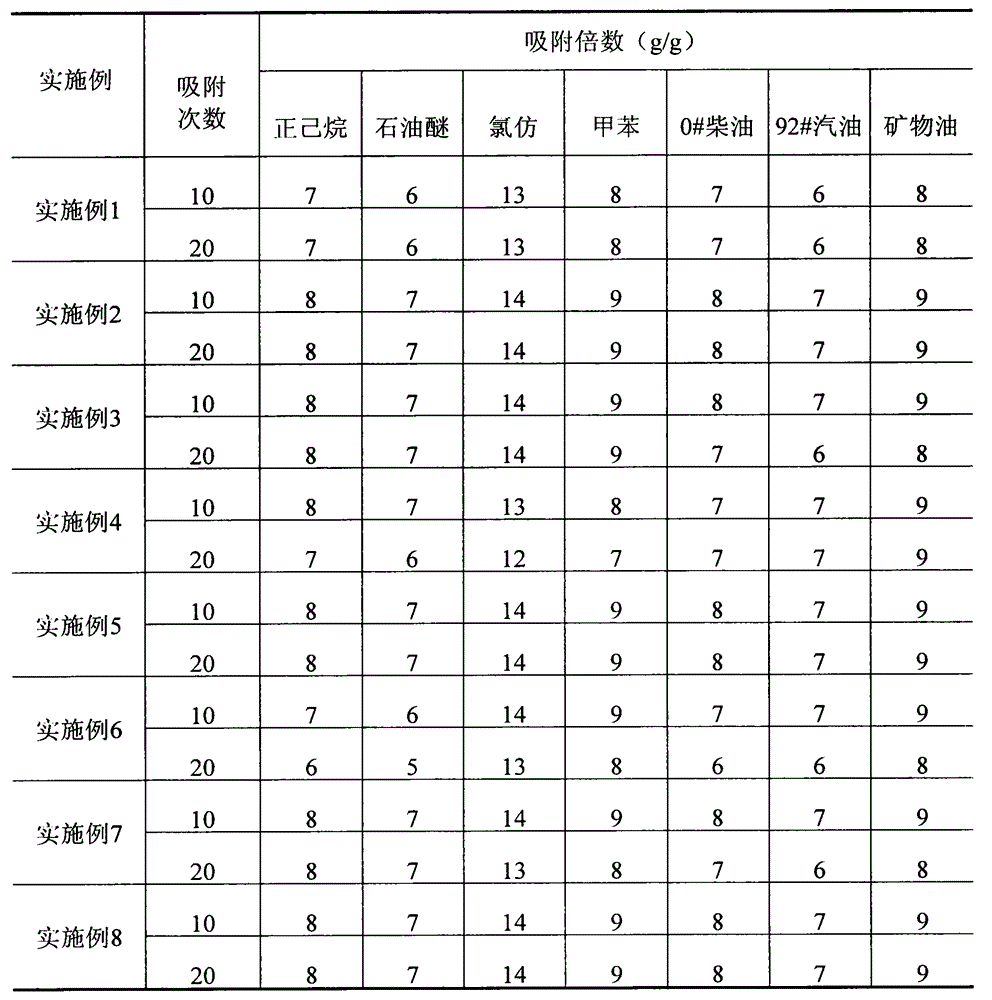

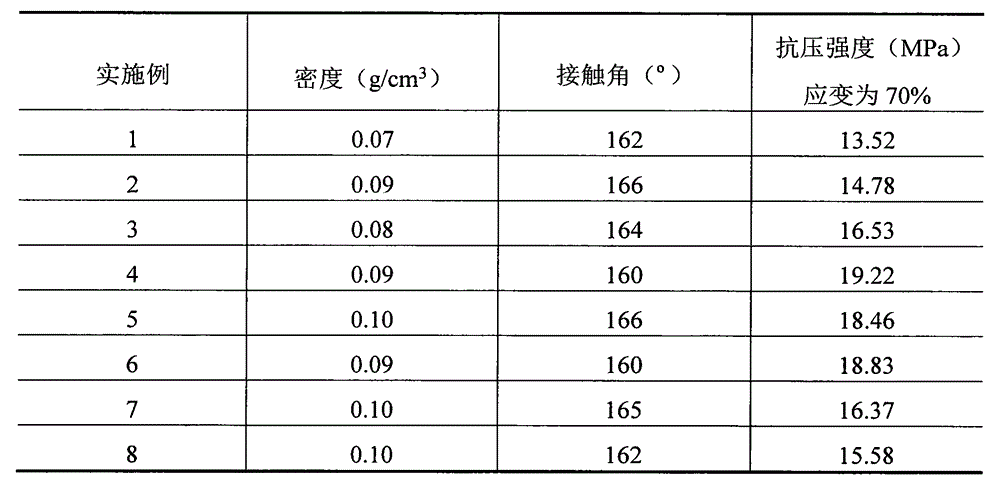

Examples

Embodiment example 1

[0027] 1) Hydrolysis reaction of cellulose reinforced phase

[0028] The microcrystalline cellulose is ground in a mortar, then passed through a 100-mesh sieve, and the under-sieve is taken. Take 0.04g of microcrystalline cellulose after grinding and add it into 50mL oxalic acid solution in which 2.7g of dodecyltrimethylammonium bromide is dissolved, stir vigorously for 10min, carry out ultrasonic solubilization for 10min, then continue stirring for 10min and then again Ultrasonic solubilization was performed for 10 min, and this operation was repeated 3 times.

[0029] 2) Hydrolysis reaction of silicon precursor

[0030] While stirring, add 10 mL of methyltrimethoxysilane, 6.33 mL of dimethyldimethoxysilane, and 1 mL of trimethylmethoxysilane to the hydrolyzate prepared in 1) above, and stir at room temperature for 1 h.

[0031] 3) Polycondensation reaction between cellulose reinforced phase and silicon precursor

[0032] 16.7g of urea was added to the sol solution prepare...

Embodiment example 2

[0036] 1) Hydrolysis reaction of cellulose reinforced phase

[0037]Put microcrystalline cellulose and methyl cellulose into a mortar and grind, then pass through a 100-mesh sieve, and take the under-sieve. Add 0.08g of microcrystalline cellulose and 0.24g of methyl cellulose after grinding to 100mL acetic acid solution dissolved with 6.4g of hexadecyltrimethylammonium bromide, stir vigorously for 15min and then ultrasonically induce dissolution for 15min , and then continue to stir for 15 minutes and then sonicate for another 15 minutes, and repeat this operation 3 times.

[0038] 2) Hydrolysis reaction of silicon precursor

[0039] While stirring, add 20 mL of methyltriethoxysilane, 12.66 mL of dimethyldiethoxysilane, and 2 mL of trimethylethoxysilane to the hydrolyzate prepared in 1) above, and stir at room temperature for 2 h.

[0040] 3) Polycondensation reaction between cellulose reinforced phase and silicon precursor

Embodiment example 3

[0045] 1) Hydrolysis reaction of cellulose reinforced phase

[0046] Put microcrystalline cellulose and propyl cellulose into a mortar and grind, then pass through a 150-mesh sieve, and take the under-sieve. Take 0.04g of microcrystalline cellulose and 0.08g of propyl cellulose after grinding and add them to 50mL formic acid solution dissolved with 2.7g of dodecyltrimethylammonium chloride, stir vigorously for 20min and then ultrasonically induce dissolution for 20min , and then continue to stir for 20 minutes and then sonicate for another 20 minutes, and repeat this operation 2 times.

[0047] 2) Hydrolysis reaction of silicon precursor

[0048] While stirring, add 10 mL of methyltrimethoxysilane, 6.33 mL of dimethyldimethoxysilane, and 1 mL of trimethylmethoxysilane to the hydrolyzate prepared in 1) above, and stir at room temperature for 1 h.

[0049] 3) Polycondensation reaction between cellulose reinforced phase and silicon precursor

[0050] 5 mL of formamide with a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com