A kind of cerium-zirconium solid solution with high oxygen storage capacity prepared by using tobacco plant as a template and its preparation method

A cerium zirconium solid solution, tobacco plant technology, applied in separation methods, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of stable performance, low production cost, and easy control of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] After removing the stem strips from the tobacco leaves after initial baking, they are cut into blades with a length of 1-2 cm and a width of 0.2 cm. Weighing 10 g of the leaf was soaked in 5% HCl for 3 days, filtered, and dehydrated through an absolute ethanol gradient to obtain a tobacco plant template. In a beaker, use 15g of precursor solution (the molar ratio of Ce(NO 3 ) 3 :ZrO(NO 3 ) 2 : citric acid=0.5:0.5:4, just dissolved in water) mixed and soaked for 3 days. After filtration, the leaves doped with cerium-zirconium solid solution were obtained, dried at room temperature and then dried in an oven at 90° C. for one day to obtain the initial solid product. The obtained solid product is put into a muffle furnace and calcined at a high temperature of 500° C. to obtain a cerium-zirconium solid solution.

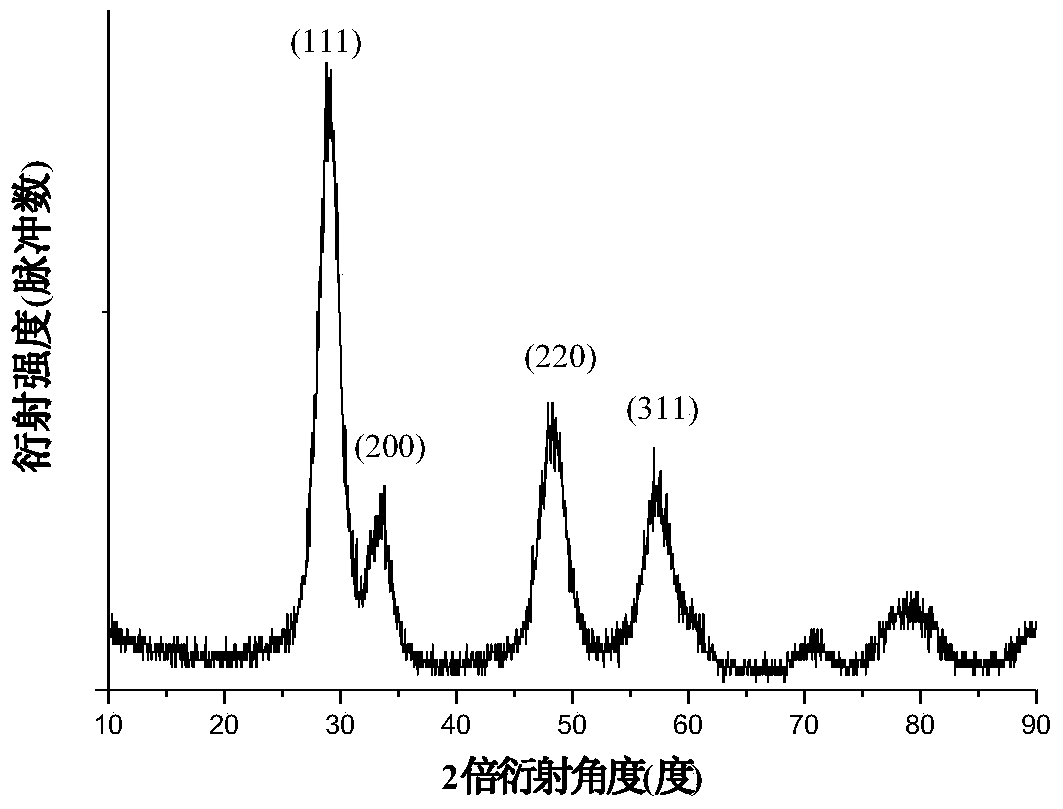

[0037] figure 1 It is the SEM image of the prepared cerium-zirconium solid solution. It can be clearly seen from the figure that the as-prepared cerium-zirc...

Embodiment 2

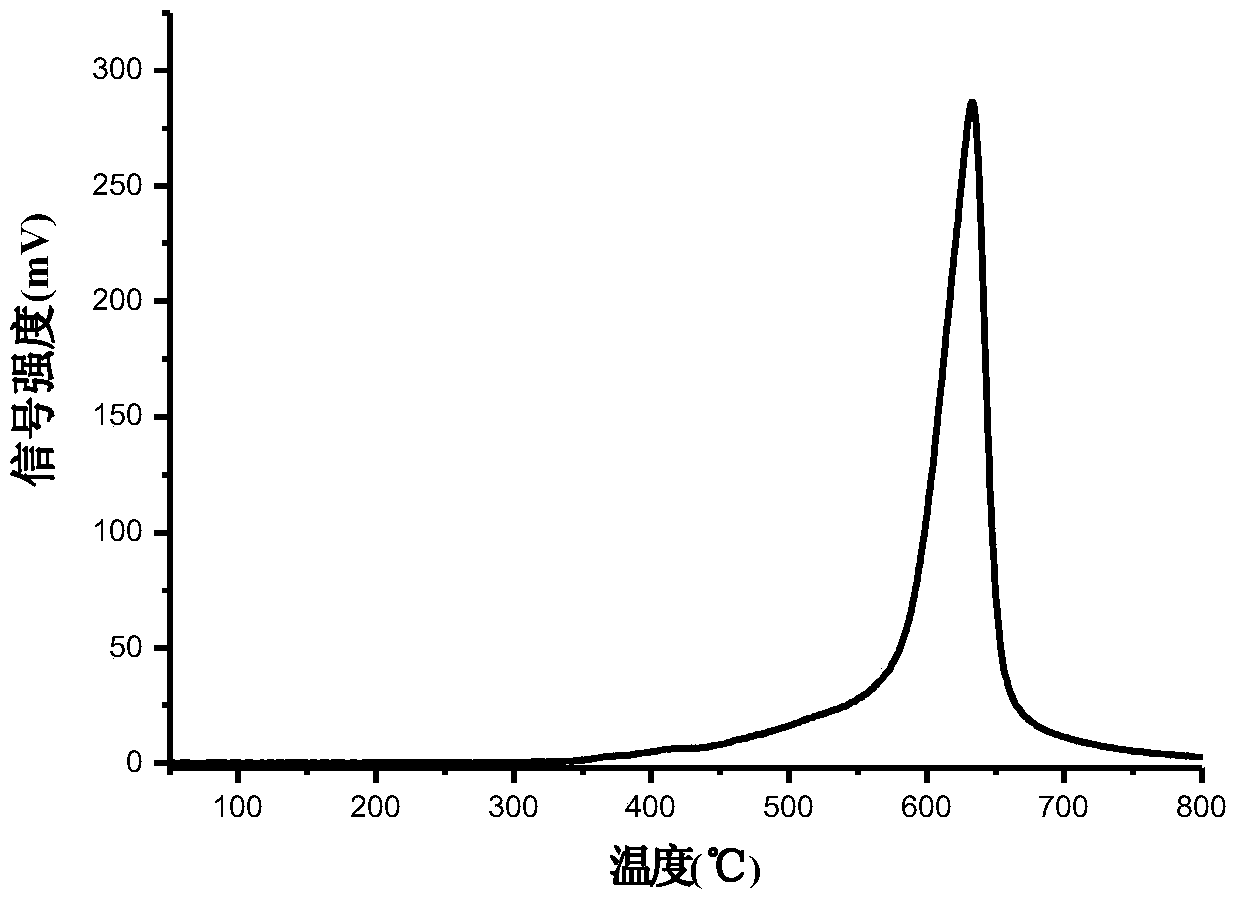

[0041] Remove the stalks from the leaves of the tobacco leaves after initial roasting, cut the stalks into 1-2 cm long, weigh 10 g, soak in 5% HCl for 3 days, filter, and dehydrate through absolute ethanol gradient to obtain a tobacco plant template. In a beaker, use 15g of precursor solution (the molar ratio of Ce(NO 3 ) 3 :ZrO(NO 3 ) 2 : tartaric acid=0.5:0.5:4, just dissolved in water) mixed and soaked for 3 days. After filtration, the stalk doped with cerium-zirconium solid solution was obtained, dried at room temperature and then dried in an oven at 90° C. for one day to obtain the initial solid product. The obtained solid product is put into a muffle furnace and calcined at a high temperature of 500° C. to obtain a cerium-zirconium solid solution. The prepared cerium-zirconium solid solution was treated with H 2 - After TPR test, with Cu 2 O calibration to calculate the hydrogen consumption, the calculated oxygen storage capacity of the cerium-zirconium solid solut...

Embodiment 3

[0043] Tobacco leaves (including leaves and stalks) after primary roasting are made into shredded tobacco after expansion technology, 10 g is weighed, soaked in 5% HCl for 2 days, filtered, and dehydrated by dehydrated ethanol gradient to obtain a tobacco plant template. In a beaker, use 15g of precursor solution (the molar ratio of Ce(NO 3 ) 3 :ZrO(NO 3 ) 2 : ethylenediaminetetraacetic acid=0.5:0.5:4, just dissolved in water) mixed and soaked for 3 days. The tobacco leaves doped with the cerium-zirconium solid solution were obtained by filtration, dried at room temperature and then dried in an oven at 90° C. for one day to obtain the initial solid product. The obtained solid product is put into a muffle furnace and calcined at a high temperature of 500° C. to obtain a cerium-zirconium solid solution. The prepared cerium-zirconium solid solution was treated with H 2 - After TPR test, with Cu 2 O calibration to calculate the hydrogen consumption, the calculated oxygen sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen storage capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com