Preparation method of inorganic nanoparticle/polymer-based composite monolithic column

A technology of inorganic nanoparticles and polymers, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve the problems of easy agglomeration and thermodynamic instability, and achieve scientific and reasonable preparation methods and long service life. , the effect of improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

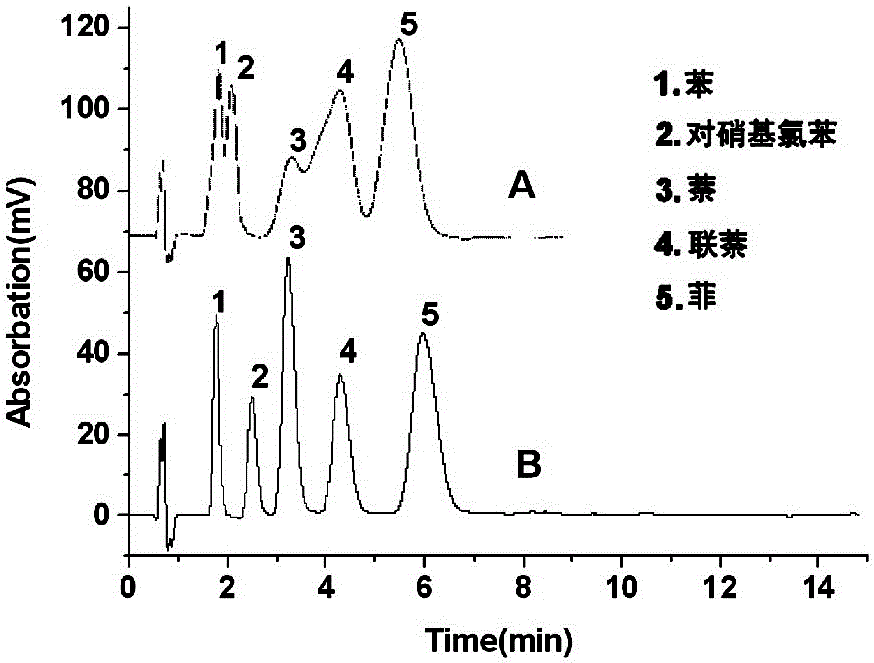

Embodiment 1

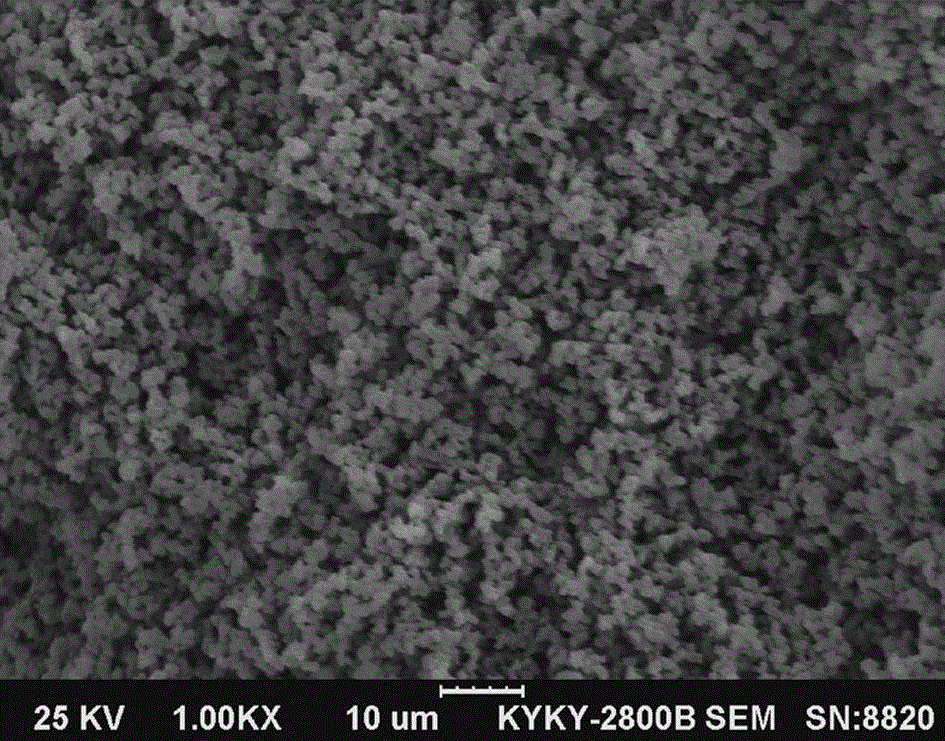

[0022] (1) Using the mixed acid reflux oxidation method, prepare a mixed acid solution with concentrated nitric acid (mass ratio concentration of 98%) and concentrated sulfuric acid (mass ratio concentration of 65%) at a volume ratio of 1:3, and take 2.0g of nano-diamonds into a 150mL flask , then add 80mL of the mixed acid solution, disperse under ultrasonic conditions for 30 min, reflux at 135°C for 8 h under magnetic stirring, centrifuge (12000 rpm, 10 min), discard the supernatant, wash three times with absolute ethanol, 110 Dry at ℃ for 24 hours to obtain carboxylated nano-diamonds;

[0023] (2) Take 1.0 g of dried carboxylated nanodiamonds in a flask, add 40 mL of thionyl chloride, add 100 μL of dimethylformamide as a catalyst, ultrasonically disperse for 1 h, and reflux at 90 ° C for 4 h under magnetic stirring , centrifuge the reacted mixed solution (12000 rpm, 10min), discard the supernatant, wash 4 times with tetrahydrofuran to obtain acyl chloride nanodiamonds; put ...

Embodiment 2

[0027] (1) Using the mixed acid reflux oxidation method, prepare a mixed acid solution with concentrated nitric acid and concentrated sulfuric acid at a volume ratio of 1:3, take 2.0g of nano-diamonds into a 150mL flask, then add 60mL of the mixed acid solution, and disperse under ultrasonic conditions for 35 minutes. Reflux at 135°C for 10 h under magnetic stirring, centrifuge (12000 rpm, 10 min), discard the supernatant, wash with absolute ethanol three times, and dry at 110°C for 24 h to obtain carboxylated nano-diamonds;

[0028] (2) Take 1.0 g of dried carboxylated nanodiamonds in a flask, add 30 mL of thionyl chloride, add 100 μL of dimethylformamide as a catalyst, ultrasonically disperse for 1 h, and reflux at 90 ° C for 5 h under magnetic stirring , centrifuge the reacted mixed solution (12000 rpm, 10min), discard the supernatant, wash 4 times with tetrahydrofuran to obtain acyl chloride nano-diamonds; put the acyl chloride nano-diamonds into 40mL of anhydrous tetrahydr...

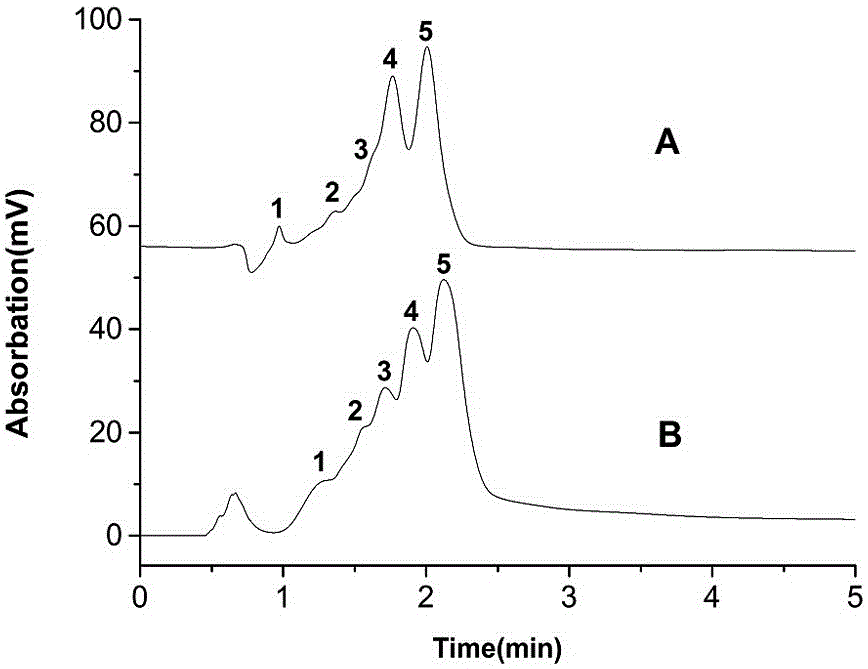

Embodiment 3

[0032] (1) Using the mixed acid reflux oxidation method, prepare a mixed acid solution with concentrated nitric acid and concentrated sulfuric acid at a volume ratio of 1:3.5, take 2.0 g of nano-diamonds into a 150 mL flask, then add 100 mL of the mixed acid solution, and disperse under ultrasonic conditions for 40 min. Reflux at 145°C for 8 h under magnetic stirring, centrifuge (12,000 rpm, 10 min), discard the supernatant, wash with absolute ethanol three times, and dry at 110°C for 24 h to obtain carboxylated nano-diamonds;

[0033] (2) Take 1.0 g of carboxylated nano-diamond after drying in a flask, add 50 mL of thionyl chloride, add 100 μL of dimethylformamide as a catalyst, ultrasonically disperse for 1 h, and reflux at 90 ° C for 6 h under magnetic stirring , centrifuge the reacted mixed solution (12000 rpm, 10min), discard the supernatant, wash 4 times with tetrahydrofuran to obtain acyl chloride nanodiamonds; put the prepared acyl chloride nanodiamonds into 40mL of anh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com