Loop heat pipe ammonia working medium purity analysis device

A loop heat pipe and purity analysis technology, applied in measurement devices, analytical materials, material separation, etc., can solve the problems of reducing detection accuracy, loss, etc., to achieve high detection accuracy, ensure purity, and reduce the effect of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

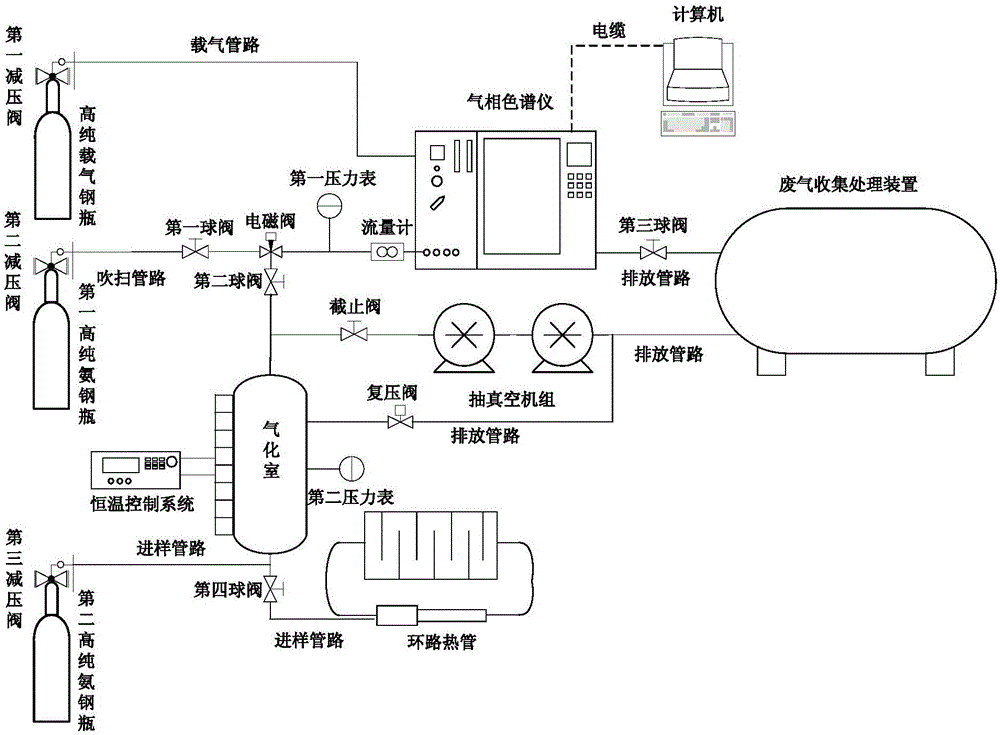

[0027] Such as figure 1 Shown is a schematic structural diagram of the loop heat pipe ammonia working medium purity analysis device of the present invention, which includes a high-purity carrier gas cylinder, a first high-purity ammonia cylinder, a second high-purity ammonia cylinder, a gasification chamber, a constant temperature control system, and a first ball valve , the second ball valve, the third ball valve, the fourth ball valve, solenoid valve, re-pressure valve, globe valve, first pressure gauge, second pressure gauge, flow meter, vacuum unit, exhaust gas collection and treatment device, gas chromatograph and computer ; Wherein, the high-purity carrier gas cylinder is connected to the gas chromatograph through the carrier gas pipeline; the first high-purity ammonia cylinder is connected to the gas chromatograph through the purge pipeli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com