Bacteriocin, and preparation method and application thereof

A technology of bacteriocin and Lactobacillus sake, which is applied in the field of bacteriocin, can solve the problems of unsatisfactory purification effect and yield, and achieve the effects of avoiding denaturation and inactivation, high yield, and good separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Isolation of Lactobacillus sake LZ217

[0045] Take fresh milk and dilute it with 0.9% physiological saline in 10-fold gradients, absorb 0.3ml of each dilution gradient and spread it on a plate containing Lactobacillus sake LZ217 screening medium, and incubate in an anaerobic manner at 37°C for 36-48 hours. Select colonies with good growth and different shapes and large calcium-dissolving circles for numbering, and repeatedly isolate and purify by plate streaking separation method, pick a single colony of Lactobacillus sake LZ217 on the plate, inoculate it into MRS liquid medium, and culture at a constant temperature of 37°C After 24 hours, the strains were numbered and preserved, and the strains were preserved at -80°C.

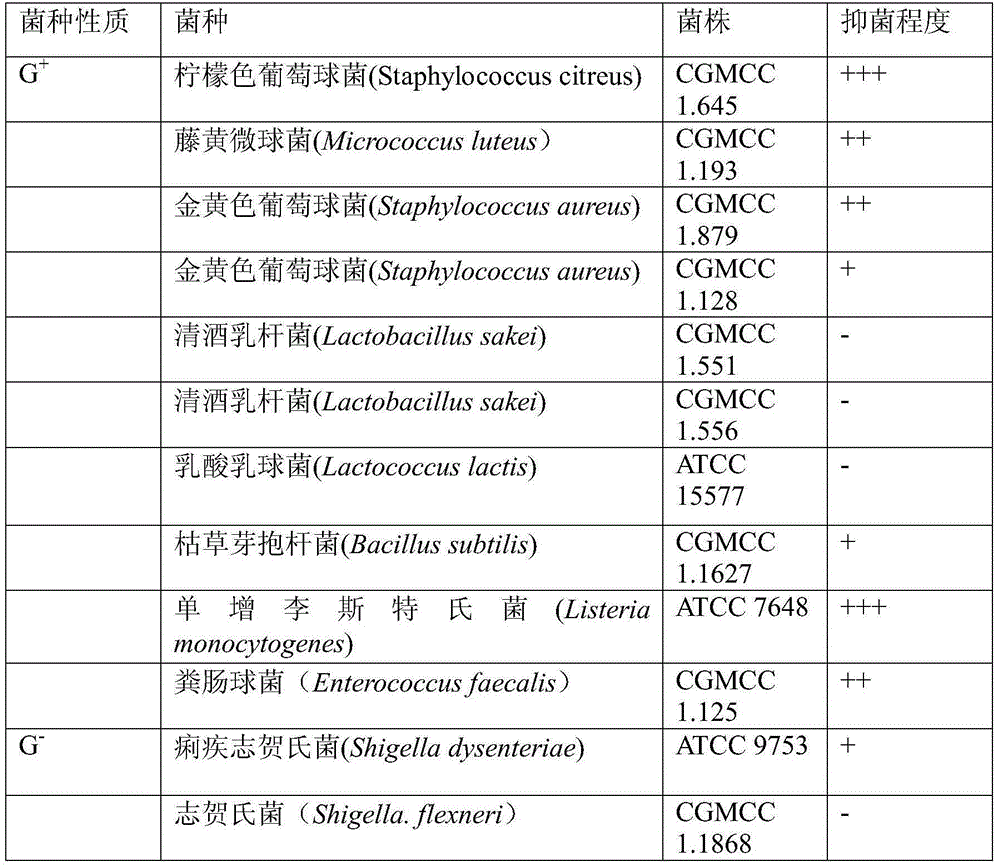

[0046] Screening of Lactobacillus sake LZ217 producing antibacterial active metabolites

[0047] Three rings of the isolated acid-producing strains were picked and inoculated into MRS liquid medium, and cultured at 37°C for 24 hours. Centrifuge at 4...

Embodiment 2

[0070] Embodiment 2: the preparation of bacteriocin

[0071] Lactobacillus sake LZ217 was inoculated in MRS liquid medium, and cultured at 37°C for 12 hours to obtain a seed liquid; inoculated at 5% inoculum size in MRS liquid medium, cultured at 37°C for 24 hours, and centrifuged to remove bacteria. Store at 4°C for later use. The centrifugation conditions were 12000 rpm, 20 min, and 4°C.

[0072] The crude extract of bacteriocin was obtained by centrifugation, and the bacteriocin was named as sake lactobacillus LZ217.

Embodiment 3

[0074] Separation and Purification of Bacteriocins (1)

[0075] The fermentation supernatant was roughly extracted by macroporous resin, and the specific experimental steps were as follows

[0076] (1) Weigh 30g of macroporous resin XAD-1180, soak it in absolute ethanol for 24 hours to fully swell and activate it, then fully rinse it with deionized water, and finally filter it with a suction filter bottle for later use.

[0077] (2) Pack the treated macroporous resin into a 2.5×30 cm glass chromatography column by a wet method, avoiding the entry of air bubbles as much as possible.

[0078] (3) 1L of fermentation supernatant was passed through the column, and the flow rate was controlled at 10mL / min. The duration is about 100min.

[0079] (4) Wash the chromatography column with 500 mL of ultrapure water to remove the residual culture solution attached to the surface of the resin.

[0080] (5) Use 200mL20% methanol solution to elute the chromatography column, the flow rate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com