Production method of high stability CoSe2 / graphene composite electrode material

A graphene composite and electrode material technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of inconvenient control of reaction ratio, poor crystallinity of particles, low catalytic activity, etc., and achieve high-efficiency electrocatalytic activity , Catalyst cost reduction, synthesis process is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

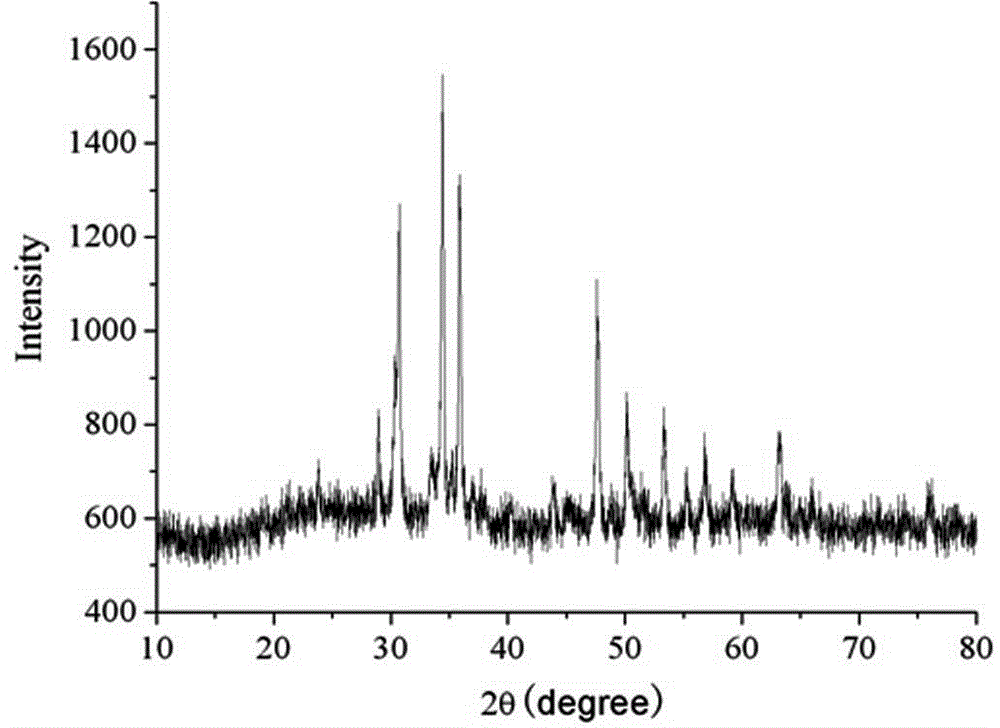

Embodiment 1

[0016] Example 1: A high stability CoSe 2 The preparation method of / graphene composite electrode material is specifically finished in the following steps:

[0017] 1. Synthesis of graphene oxide: Accurately weigh 200 mg of graphite oxide, disperse it in 100 mL of glucose solution, ultrasonically and centrifuge, and collect the supernatant to obtain graphene oxide solution;

[0018] 2. Prepare the mixed sol of cobalt hydroxide and graphene oxide: Measure 10mL of ethylene glycol, add 1.0mL of low-concentration ammonia water dropwise, stir at a constant speed, dissolve a certain amount of cobalt acetate in the graphene oxide solution, and add it dropwise to B In diol, at 75 ° C, continuous gradient stirring at a constant speed for 1.5 hours, that is, a uniform cobalt hydroxide and graphene oxide mixed sol is formed;

[0019] 3. Constant temperature vacuum aging: vacuum aging for 5 hours, control temperature at 30°C, and vacuum degree of 70Pa;

[0020] 4. Preparation of CoSe ...

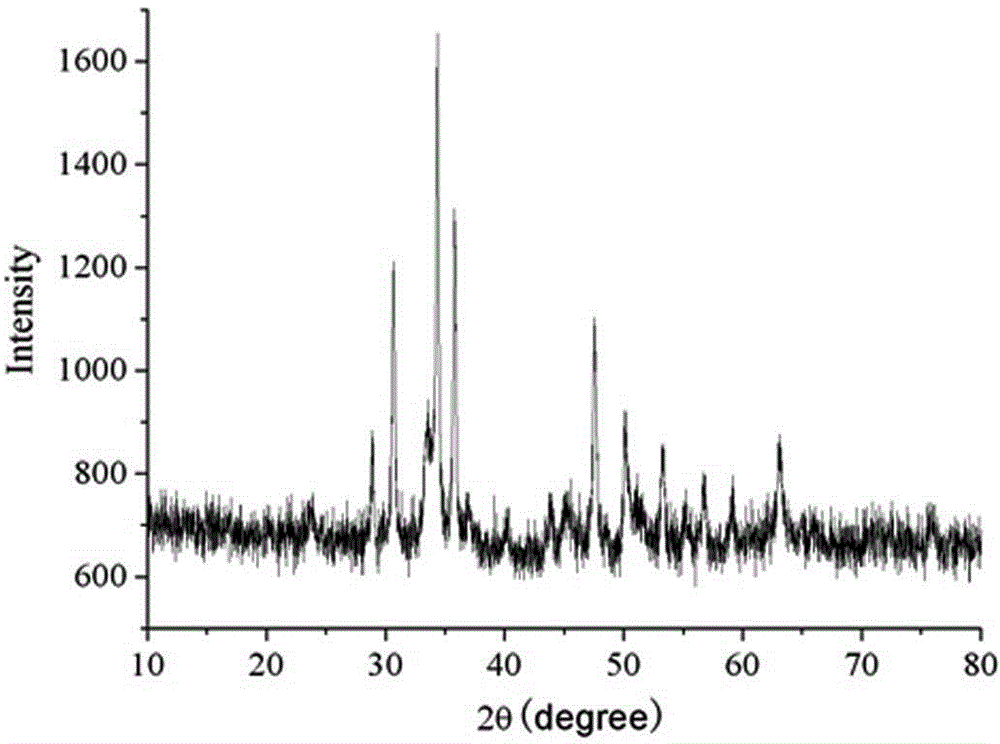

Embodiment 2

[0024] Example 2: A high stability CoSe 2 The preparation method of / graphene composite electrode material is specifically finished in the following steps:

[0025] 1. Synthesis of graphene oxide: Accurately weigh 200 mg of graphite oxide, disperse it in 100 mL of glucose solution, ultrasonically and centrifuge, collect the supernatant, and then prepare the graphene oxide solution;

[0026] 2. Prepare the mixed sol of cobalt hydroxide and graphene oxide: Measure 12mL of ethylene glycol, add 1.2mL of low-concentration ammonia water dropwise, stir at a constant speed, dissolve a certain amount of cobalt acetate in the graphene oxide solution, and then add it dropwise to B In diol, at 75 ° C, continuous gradient stirring at a constant speed for 1.0 hour, that is, a uniform mixed sol of cobalt hydroxide and graphene oxide is formed;

[0027] 3. Constant temperature vacuum aging: vacuum aging for 8 hours, control temperature at 45°C, and vacuum degree of 70Pa;

[0028] 4. Prepar...

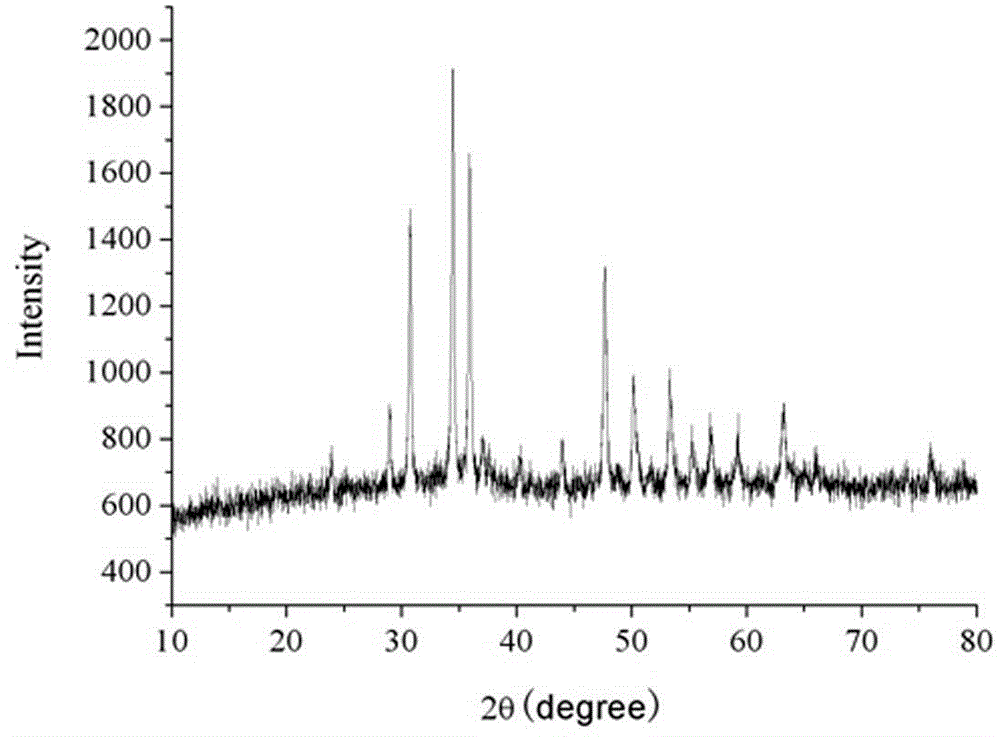

Embodiment 3

[0032] Example 3: A high stability CoSe 2 The preparation method of / graphene composite electrode material is specifically finished in the following steps:

[0033] 1. Synthesis of graphene oxide: Accurately weigh 200 mg of graphite oxide, disperse it in 100 mL of glucose solution, ultrasonically and centrifuge, collect the supernatant, and then prepare the graphene oxide solution;

[0034] 2. Prepare the mixed sol of cobalt hydroxide and graphene oxide: Measure 15mL of ethylene glycol, add 2.5mL of low-concentration ammonia water dropwise, stir at a constant speed, dissolve a certain amount of cobalt acetate in the graphene oxide solution, and add it dropwise to In diol, at 72 ° C, continuous gradient stirring at a constant speed for 0.5 hours, that is, a uniform mixed sol of cobalt hydroxide and graphene oxide is formed;

[0035] 3. Constant temperature vacuum aging: vacuum aging for 9 hours, control temperature at 60°C, and vacuum degree of 70Pa;

[0036] 4. Preparation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com