Easy-to-wash PVDF (polyvinylidene fluoride) ultrafiltration membrane and preparation method thereof

A technology of polyvinylidene fluoride and polyvinylidene fluoride powder, which is applied in the field of easy-to-clean polyvinylidene fluoride ultrafiltration membrane and its preparation, can solve the problems of high cost, poor compatibility, and easy agglomeration, and achieve high The effect of specific surface area, large reserves and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The raw materials for preparing the ultrafiltration membrane include the following components: polyvinylidene fluoride powder, organic solvent, poly-N-isopropylacrylamide modified attapulgite, additives, and coagulation bath.

[0033] The organic solvent here refers to a solvent capable of dissolving polyvinylidene fluoride powder, such as: N-methyl-2-pyrrolidone, tetrahydrofuran, dimethyl sulfoxide; amides such as dimethylacetamide and dimethylformamide ; Ester solvents such as trimethyl phosphate or triethyl phosphate; Lactone solvents such as γ-butyrolactone; and their mixed solvents.

Embodiment 1

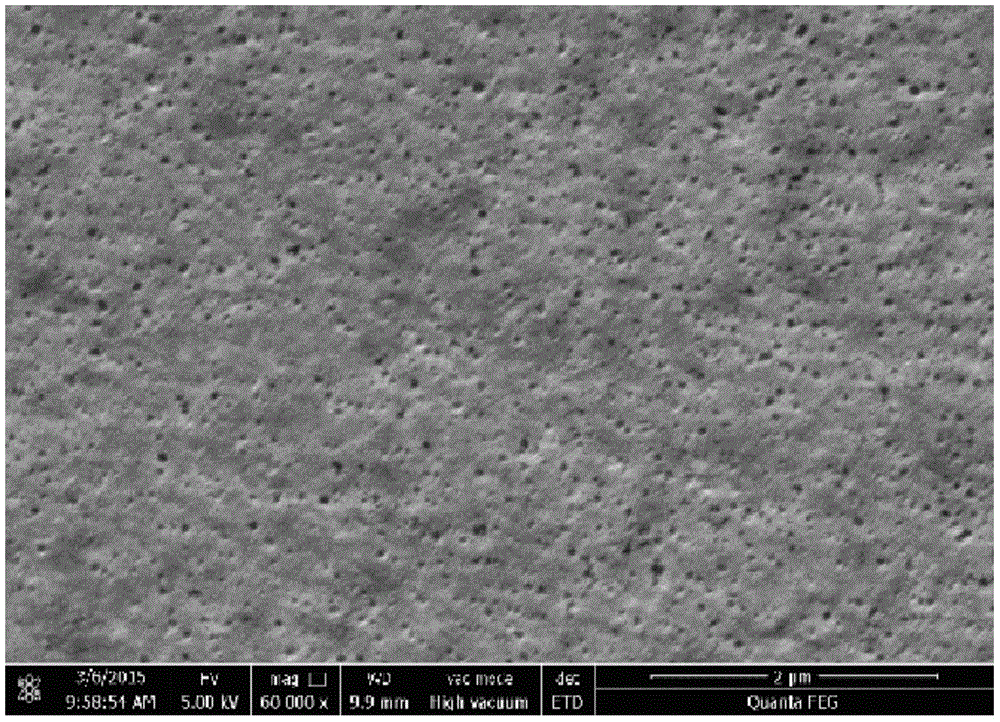

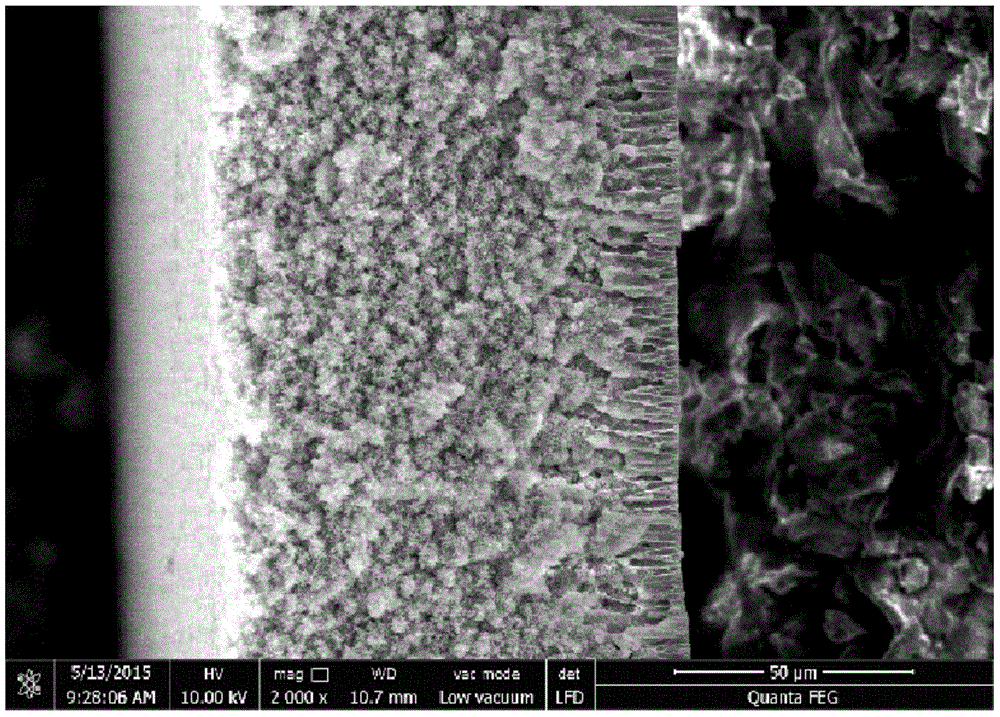

[0047] Example 1 Preparation of polyvinylidene fluoride / modified attapulgite mixed matrix ultrafiltration membrane

[0048] Add 4g of attapulgite modified by silane coupling agent KH-570 into the three-necked flask (see patent document 104128100A for the preparation method), then add 50mL of water, ultrasonically disperse until uniform, and then add the initiator azobisisobutyl Nitrile 0.2g, monomer N-isopropylacrylamide 0.6g, react at 70°C for 12 hours, the reaction product is centrifuged and washed with deionized water and absolute ethanol several times to remove excess reactants, and then vacuum dried Grinding and sieving to obtain attapulgite modified by poly-N-isopropylacrylamide.

[0049] Then respectively add 1%, 4%, 7% (relative to the mass of polyvinylidene fluoride powder) of the modified attapulgite prepared above into 48g of triethyl phosphate, after ultrasonic dispersion is uniform, add 12g of polyvinylidene fluoride Stir and dissolve the vinylidene fluoride powd...

Embodiment 2

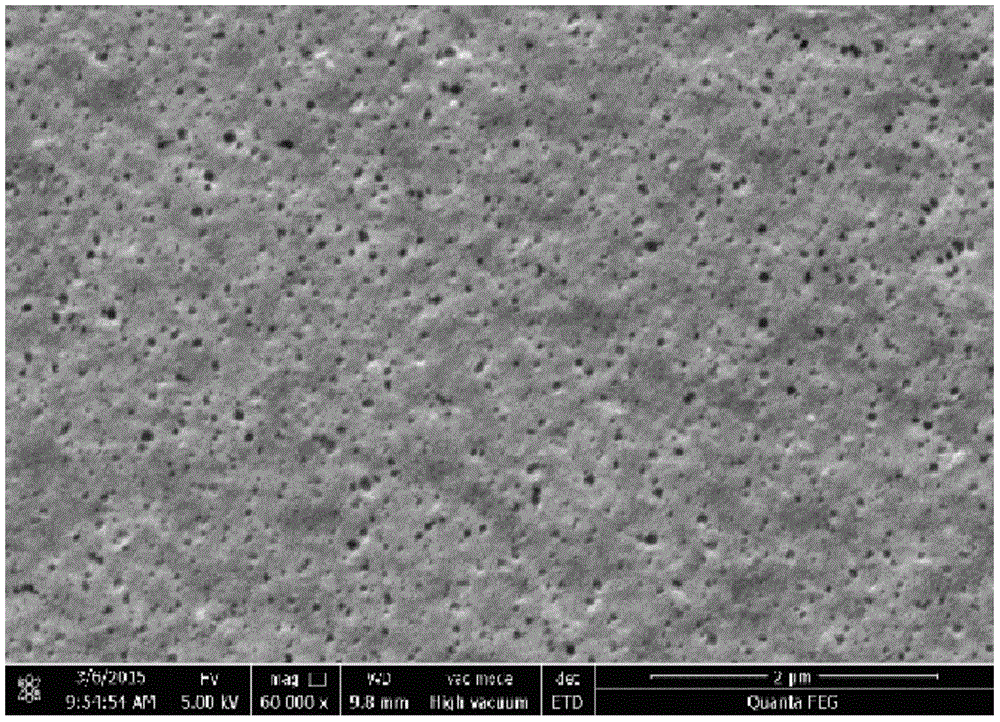

[0054] Example 2 Preparation of polyvinylidene fluoride / modified attapulgite mixed matrix ultrafiltration membrane

[0055] Add 4g of silane coupling agent A-150 (vinyltrichlorosilane), A-151 (vinyltriethoxysilane), and KH-570 modified attapulgite in the three-necked flask (for the preparation method, refer to Patent document 104128100A), then add 50mL of water, ultrasonically disperse until uniform, then add in turn 0.3g of initiator azobisisobutyronitrile, 0.5g of monomer N-isopropylacrylamide, react at 75°C for 8 hours, the reaction product After centrifugation, it is washed with deionized water and absolute ethanol several times to remove excess reactants, and then vacuum-dried, ground and sieved to obtain poly-N-isopropylacrylamide-modified attapulgite.

[0056] Then add 4% (relative to the quality of polyvinylidene fluoride powder) of the modified attapulgite prepared above into 42 g of triethyl phosphate, and after ultrasonic dispersion is uniform, add 15 g of polyvinyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com