TFT ion sensor and TFT ion sensor apparatus using the same

一种离子传感器、离子敏感的技术,应用在测量装置、仪器、科学仪器等方向,能够解决不能提高灵敏度、难检测激素等微量浓度物质等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

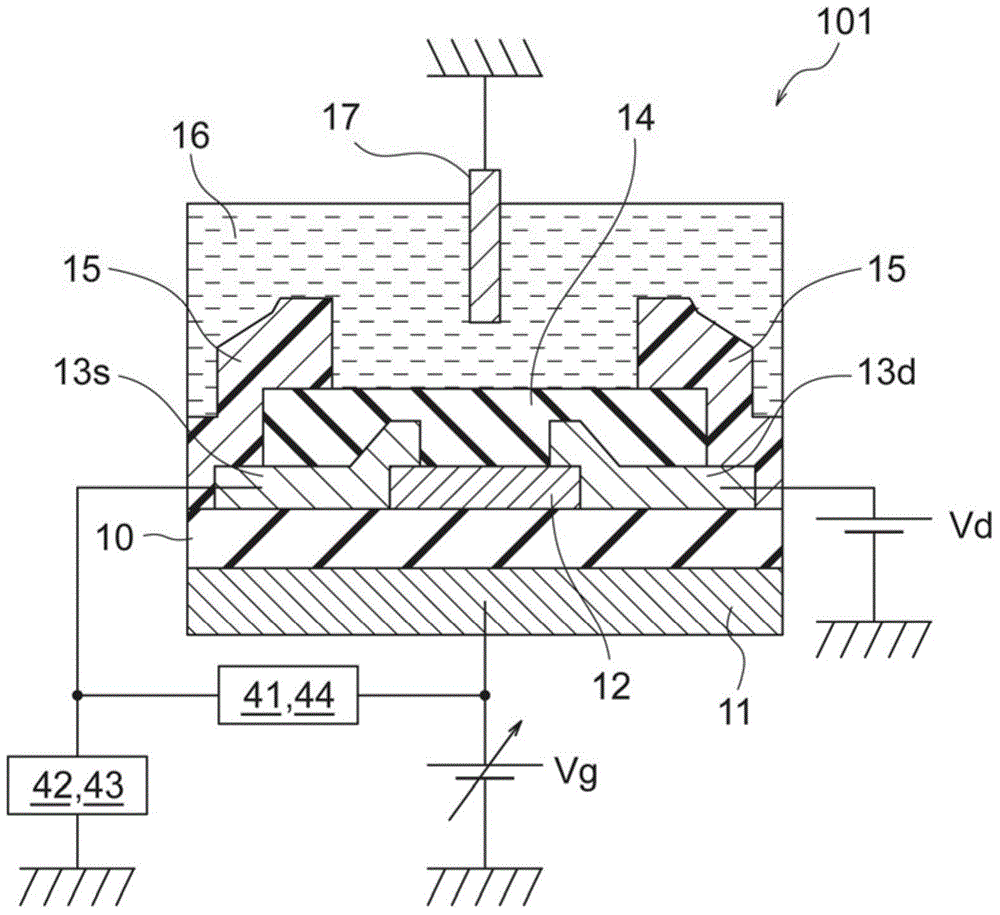

[0053] Next, refer to figure 1 A further concrete example 1 of the first exemplary embodiment will be described.

[0054] First, a silicon substrate 11 on which a 200 nm-thick thermal oxide film 10 is formed is prepared. Instead of the thermal oxide film 10, a silicon oxide film, a silicon nitride film, or the like deposited by a plasma CVD (Chemical Vapor Deposition) method or a sputtering method may be used.

[0055] In addition, a 50-nm-thick oxide semiconductor film made of In—Ga—Zn—O was deposited on the silicon substrate 11 on which the thermally oxidized film 10 was formed by a sputtering method using a metal mask. At this time, a sintered object made of In-Ga-Zn-O was used, and a DC (Direct Current) sputtering method was used in a mixed gas atmosphere of argon and oxygen without heating the substrate. After deposition, it was annealed at 400° C. for one hour. The island-shaped semiconductor active layer 12 is formed by patterning the oxide semiconductor film.

[0...

Embodiment 2

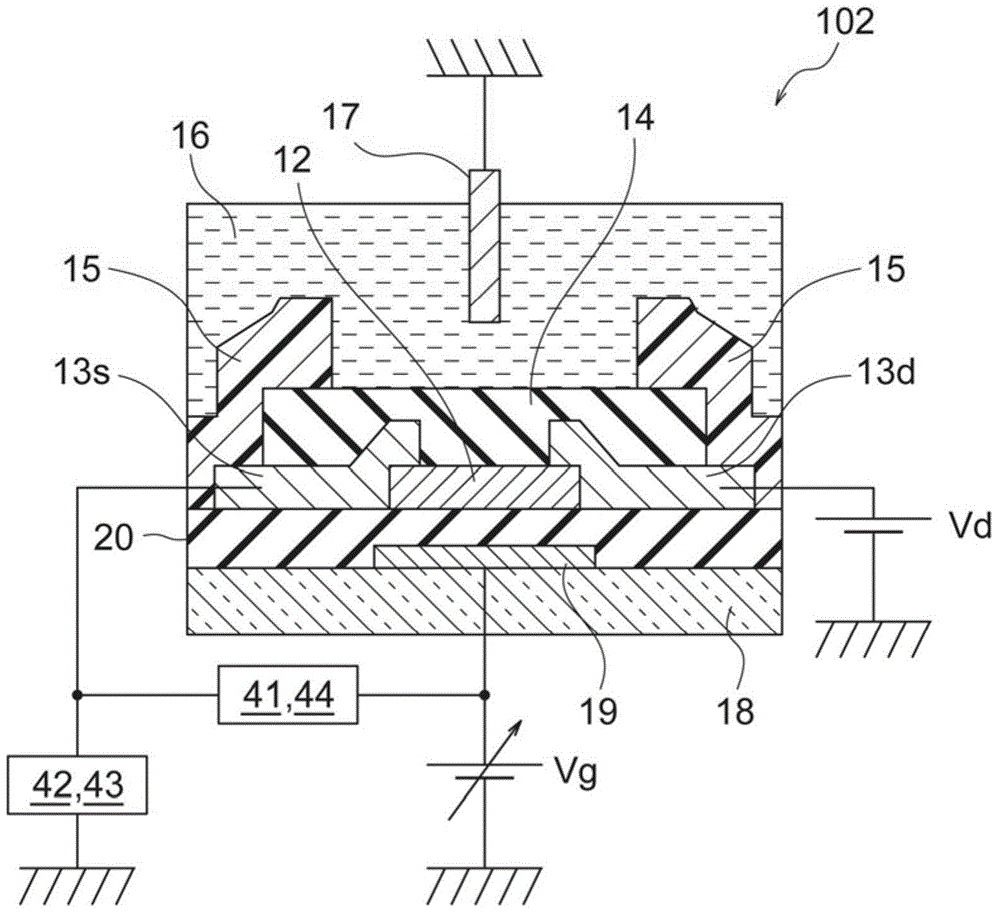

[0076] Next, refer to image 3 Example 2 in which the second exemplary embodiment is further embodied will be described.

[0077] An alloy material mainly composed of aluminum is deposited on the glass substrate 18 by sputtering, and a gate electrode 19 is formed by using a photolithography process including resist coating, exposure, development, etching, and resist stripping.

[0078] Next, a gate insulating film 20 was formed by depositing a 300 nm-thick silicon oxide film at a substrate temperature of 350C by using a plasma CVD method.

[0079] Next, an oxide semiconductor film composed of In—Ga—Zn—O was deposited to a thickness of 30 nm by sputtering, and patterned into a predetermined island shape by a photolithography process to form the semiconductor active layer 12 . After patterning, an annealing treatment was performed at 400° C. for 1 hour in air.

[0080] Then, titanium metal was deposited by sputtering, and after patterning the photoresist, a fluorine-based plas...

Embodiment 3

[0087] (Example 3) Etching stop type IGZO-TFT

[0088] Figure 4 It is a sectional view showing the TFT ion sensor 103 of the third embodiment. refer to Figure 4 Example 3, which is a modified example of the second exemplary embodiment, will be described.

[0089] An alloy material mainly composed of molybdenum is deposited on the glass substrate 18 by sputtering, and the gate electrode 19 is formed by using a photolithography process consisting of resist coating, exposure, development, etching, and resist stripping. .

[0090] Next, by using a plasma CVD method at a substrate temperature of 350° C., a 200-nm-thick silicon nitride film 21 is deposited thereon and a 100-nm-thick silicon oxide film 22 is successively deposited, and their 300-nm-thick laminated film is used as a gate electrode. pole insulating film.

[0091] Next, an oxide semiconductor film 23 composed of In—Sn—Zn—O was deposited to a thickness of 50 nm by sputtering as a semiconductor active layer, and pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sensitivity | aaaaa | aaaaa |

| sensitivity | aaaaa | aaaaa |

| sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com