Titanium and titanium alloy surface antioxidant wear-resistant composite coating and manufacturing method thereof

A technology of composite coating and anti-oxidation layer, which is applied in the direction of metal material coating process, coating, anodic oxidation, etc., to achieve the effect of simple method and meeting the requirements of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

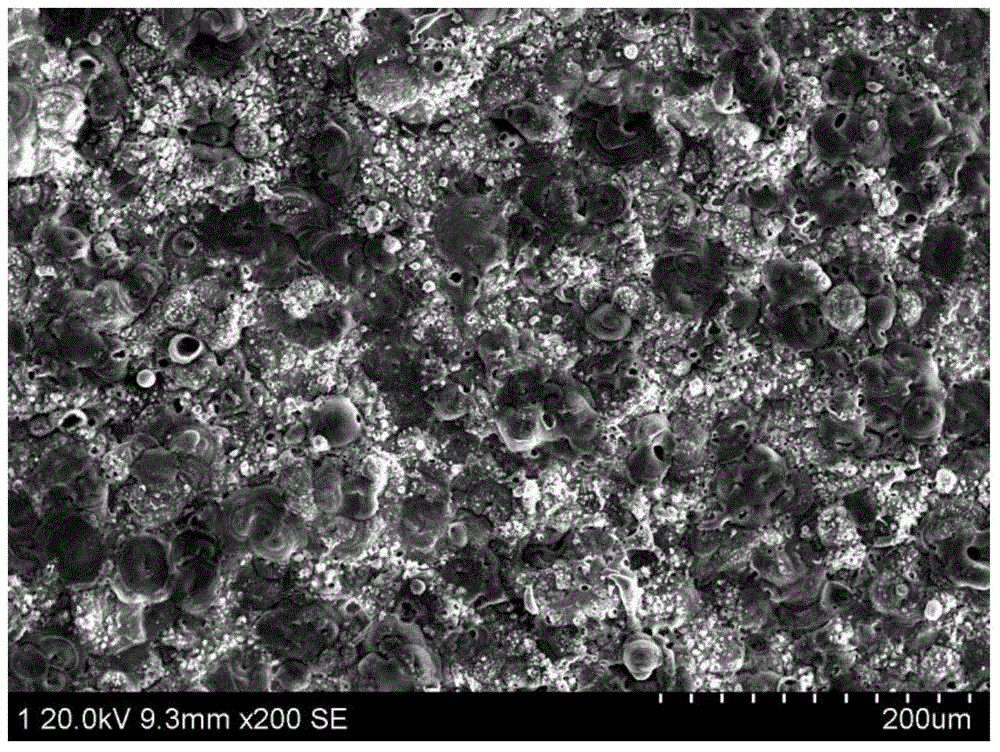

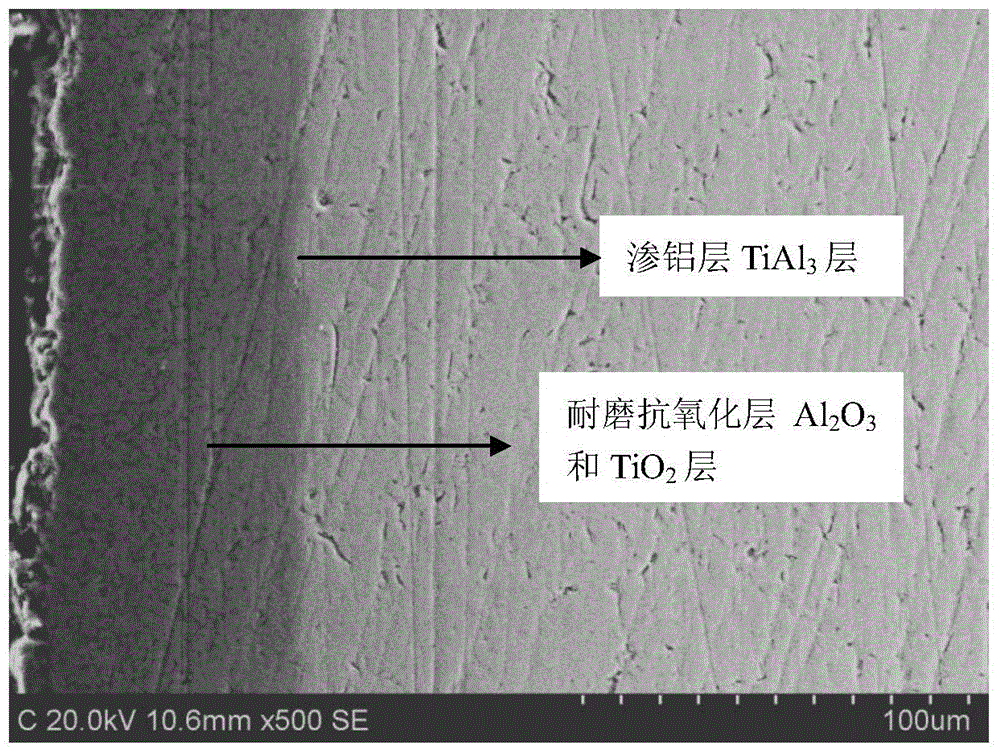

Image

Examples

Embodiment 1

[0025] (1) Use 50×100×2mm TA2 plates, degrease for 15 minutes in 50g / L sodium hydroxide solution at 85°C, and then rinse with running water;

[0026] (2) At room temperature, put the sample into HNO containing 35% mass concentration 3 Wash with mixed acid containing 4% HF for 50s to remove the scale on the surface of the TA2 sample, take it out and rinse it with running water;

[0027] (3) Dry the sample, immerse it in molten aluminum liquid at 690°C, and dip-coat it for 15 minutes to obtain an aluminum coating;

[0028] (4) The sample is then thermally diffused at 900°C for 480 minutes in a box-type resistivity furnace, and then air-cooled to room temperature to obtain an aluminum-rich aluminized coating;

[0029] (5) In the electrolyte composed of 5g / L sodium silicate and 2g / L sodium hydroxide, set the positive pulse width to 1000μs, the negative pulse width to 1000μs, the interval between pulses to 1000μs, the number of pulses to 1, and the processing time to be 90min , u...

Embodiment 2

[0032] (1) Use a 50×100×2mm TC4 plate, ultrasonically clean it for 30 minutes in acetone solution, and then rinse it with running water;

[0033] (2) At room temperature, put the sample into HNO containing 30% mass concentration 3 Wash with mixed acid containing 5% HF for 30s, remove the scale on the surface of TC4 sample, take it out and rinse it with running water;

[0034] (3) Drying the pretreated titanium alloy, immersing it in molten aluminum liquid at 730°C, and dipping for 2 minutes to obtain an aluminum coating;

[0035] (4) In a box-type resistivity furnace, thermal diffusion treatment was performed at 800°C for 30 minutes, and then air-cooled to room temperature to obtain an aluminum-rich aluminized coating;

[0036] (5) In the electrolyte composed of 5g / L sodium silicate and 2g / L sodium hydroxide, the pulse width is set to 120μs, the pulse interval is 880μs, and the number of pulses is 1. The treated TC4 sample was subjected to micro-arc oxidation treatment for 6...

Embodiment 3

[0039](1) Use a 50×100×2mm TC4 plate, ultrasonically clean it for 30 minutes in acetone solution, and then rinse it with running water;

[0040] (2) At room temperature, put the sample into HNO containing 40% mass concentration 3 Wash with mixed acid composed of HF with a mass concentration of 3% for 30s, remove the scale on the surface of the TC4 sample, and take it out and rinse it with running water;

[0041] (3) Drying the pretreated titanium alloy, immersing it in molten aluminum liquid at 750°C, and dipping for 2 minutes to obtain an aluminum coating;

[0042] (4) In a box-type resistivity furnace, thermal diffusion treatment was performed at 800°C for 30 minutes, and then air-cooled to room temperature to obtain an aluminum-rich aluminized coating;

[0043] (5) In the electrolyte composed of sodium hexametaphosphate 5g / L and disodium hydrogen phosphate 6g / L, set the pulse width to 120μs, the pulse interval to 880μs, the number of pulses to 1, and the current density to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com