Iron-doped silica sol composite abrasive grain, and polishing solution composition and preparation method thereof

A polishing liquid composition, a technology of silica sol, applied in polishing compositions containing abrasives, chemical instruments and methods, other chemical processes, etc., can solve the problem of low polishing rate, low production efficiency, surface quality to be further improved, etc. problem, to achieve the effect of increasing the polishing rate and increasing the removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

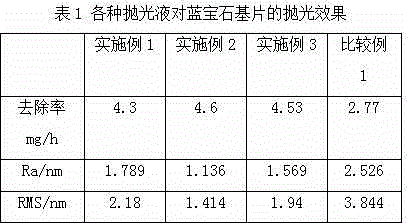

Embodiment 1

[0027] The iron-doped silica sol composite abrasive grains of the present invention can be prepared by a co-precipitation method. The preparation process is as follows: in the process of preparing the silica sol by the ion exchange method, the iron element is doped into the silica sol particles by co-precipitation. Pass the water glass with a mass fraction of 8.0% through the cation exchange resin, and receive the outflowing liquid when the pH value of the outflowing liquid is between 2.5-3.5, and then obtain a mass fraction of 2.0-3.0% active silicic acid solution; at 100°C and Under stirring, add 750 grams of ferric chloride solution with a mass fraction of 0.29% and 750 grams of an active silicic acid solution with a mass fraction of 2.0-3.0% into 3000 grams of a 10% seed crystal silica solution, and dropwise A sodium hydroxide solution with a mass fraction of 0.4% is used to control the dropping rate, to keep the liquid level of the silicon oxide seed crystal mother liquor...

Embodiment 2

[0033] 1500g of ferric chloride solution with a mass fraction of 0.29% and 1500g of a mass fraction of 2.0-3.0% active silicic acid solution are used. Finally, a polishing solution doped with iron element-doped silica sol composite abrasive grains with a mass ratio of 0.96% was obtained.

[0034] The doping mass ratio is 0.96% The composition and mass percentage of the iron-doped colloidal silicon oxide composite abrasive polishing fluid are as follows:

[0035] Iron-doped silica sol composite abrasive grains 6.06 wt.%

[0036] Dispersant sodium hexametaphosphate 2 wt.%

[0037] Deionized water 91.94 wt.%

Embodiment 3

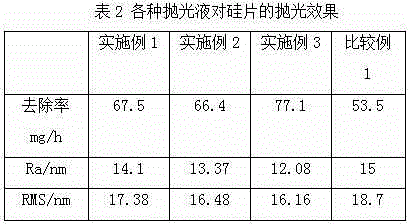

[0039] Use 3000g of ferric chloride solution with a mass fraction of 0.29% and 3000g of a mass fraction of 2.0-3.0% active silicic acid solution to mix evenly. Finally, a polishing solution doped with iron element doped silica sol composite abrasive grains with a doping mass ratio of 1.91% was obtained.

[0040] The doping mass ratio is 1.91% The composition and mass percentage of the iron-doped colloidal silicon oxide composite abrasive polishing fluid are as follows:

[0041] Iron doped silica sol composite abrasive grains 6.12 wt.%

[0042] Dispersant sodium hexametaphosphate 2 wt.%

[0043] Deionized water 91.88 wt.%

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com