Rare earth thick film circuit electric heating chip and manufacturing technology thereof

A technology of rare earth thick film and electric heating chip, which is applied in the direction of electric heating device, ohmic resistance heating, electrical components, etc., and can solve the problems that cannot be compared with it, and the scope of application is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

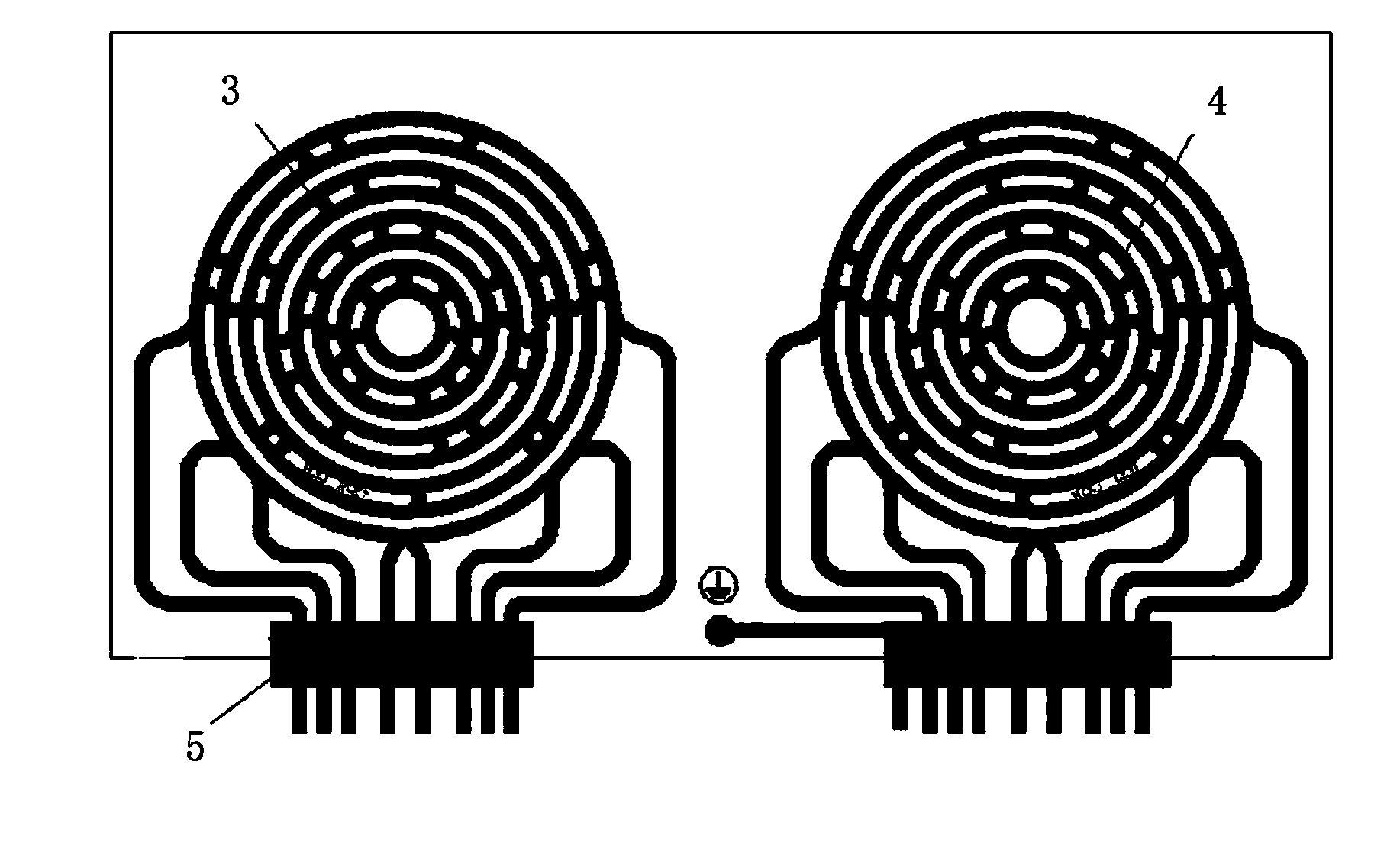

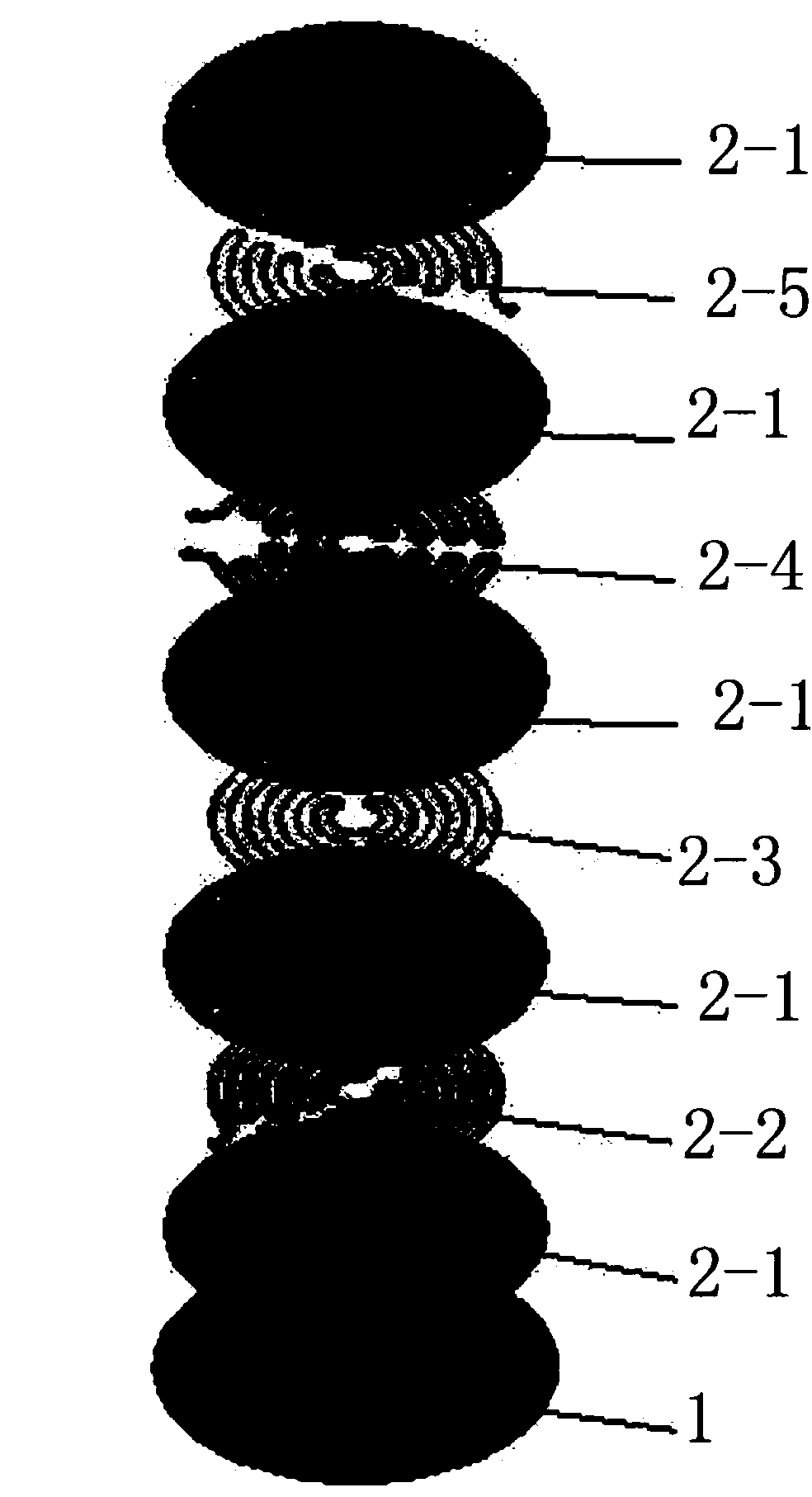

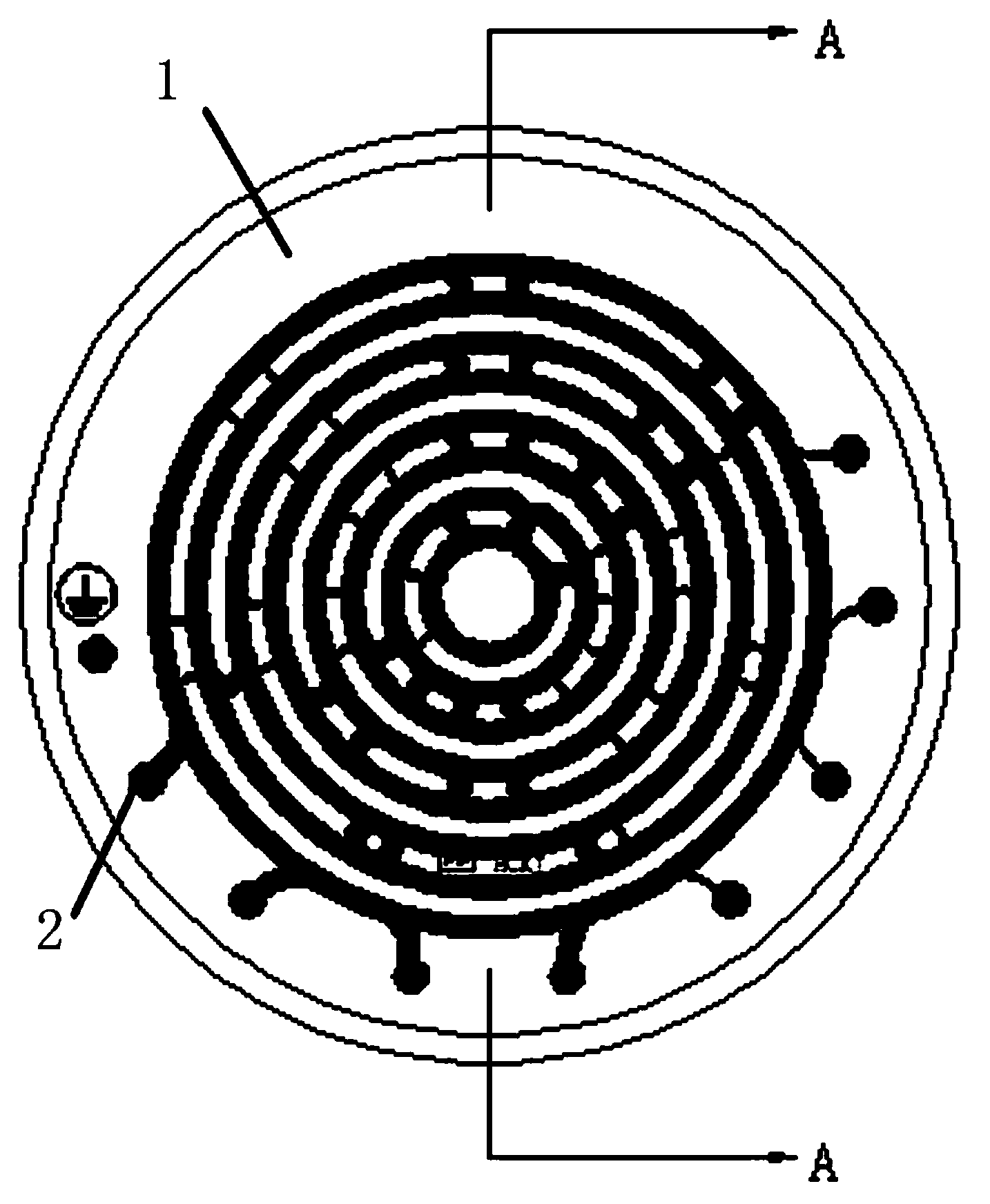

[0057] A preparation process of a rare earth thick film circuit electric heating chip, which includes the following steps:

[0058] a. Preparation of the film: prepare electronic paste, and prepare green ceramic tapes of different properties and specifications on the casting machine, including dielectric green porcelain belt, thermistor green porcelain belt, resistor green porcelain belt, electrode green porcelain belt, The sintered green ceramic tape is called thick film circuit, collectively called rare earth thick film circuit; and dried in the machine at 80~150℃ for 30~50 minutes to obtain a tape green embryo with a thickness of 0.2~3mm, which is laser cut and stamped. .

[0059] b. Preparation of the chip: Put the prepared raw tape on the aluminum-copper-Cu+ composite substrate with glass glue or silica gel, place it in the tooling, install it in a hot isostatic press, and sinter it according to the temperature curve in a nitriding atmosphere. , Cooling rate: 50-70℃ / min, peak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com