Brownification fluid for processing printed circuit board on basis of functionalized ionic liquid

A technology for printed circuit boards and ionic liquids, applied in the direction of metal material coating process, etc., can solve the problems of ecological environment and people's health hazards, destruction of blood circulation and respiratory function, eutrophication, etc., to achieve copper loading , good cycle performance, excellent heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

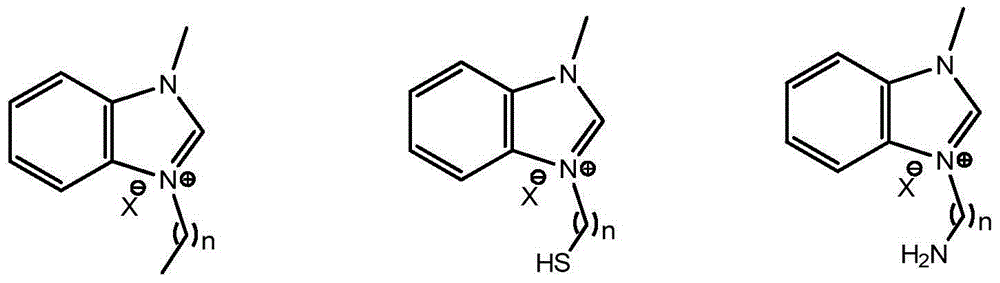

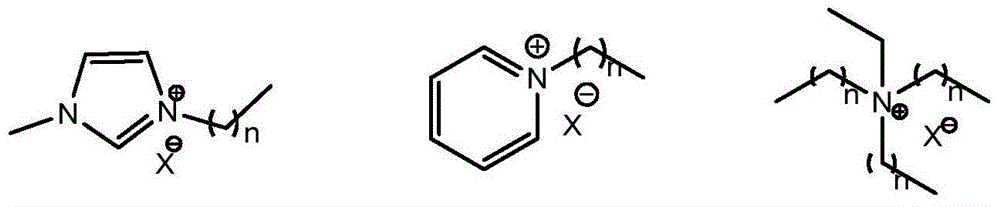

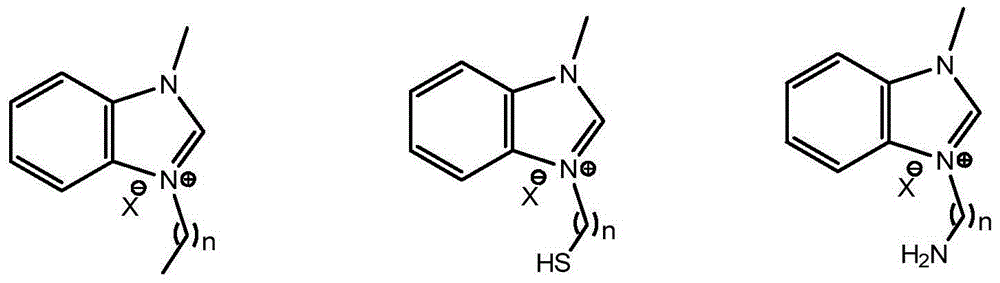

Method used

Image

Examples

Embodiment 1

[0027] The browning treatment process is to carry out copper surface treatment on the production board after the inner layer cutting, inner layer D / F, and inner layer etching board, and generate an oxide layer on the surface of the inner layer copper foil to improve the lamination of multilayer circuit boards. When the bonding force between copper foil and epoxy resin (common black oxidation and brown oxidation, etc.) process.

[0028] The technical route of browning process is as follows:

[0029] Pickling→water washing→alkaline degreasing→water washing→presoaking→browning→pure water washing→drying→pressing

[0030] The specific operation of the above technical route is as follows:

[0031] (1) Pickling: use 3%-5% dilute sulfuric acid as the cleaning agent, and wash away other metal impurities loaded on the copper surface at 30°C;

[0032] (2) Washing: Repeated washing with deionized water at room temperature until the lotion is basically neutral;

[0033] (3) Alkaline deg...

Embodiment 2

[0049]The difference of this embodiment, such as embodiment 1, is:

[0050] (1) Browning solution for printed circuit board processing based on functionalized ionic liquid, the raw material is composed of:

[0051] The concentration of concentrated sulfuric acid in the browning agent composition is 100g / L;

[0052] The hydrogen peroxide concentration is 15g / L;

[0053] The ionic liquid corrosion inhibitor is 1-methyl-4-hexylbenzimidazolium bromide, and its concentration is 10g / L;

[0054] The ionic liquid binding force accelerator is 1-methyl-4-butylpyridinium chloride salt, and its concentration is 1.0g / L.

[0055] (2) The browning temperature is 40°C, and the browning time is 50s.

[0056] After testing, the copper loading capacity of the obtained browning solution is 50g / L, and the copper surface after browning treatment can obtain a uniform and rough surface, and has stable bonding force and excellent heat resistance with the prepreg. Under the condition of 10s impact ...

Embodiment 3

[0058] The difference of this embodiment, such as embodiment 1, is:

[0059] (1) Browning solution for printed circuit board processing based on functionalized ionic liquid, the raw material is composed of:

[0060] The concentrated sulfuric acid concentration in the browning agent composition is 120g / L;

[0061] The hydrogen peroxide concentration is 20g / L;

[0062] The ionic liquid corrosion inhibitor is 1‐methyl‐4‐mercapto substituted ethylbenzimidazolium bromide, and its concentration is 12g / L;

[0063] The ionic liquid binding force accelerator is 1-methyl-4-butyl quaternary ammonium chloride salt, and its concentration is 1.5g / L.

[0064] (2) The browning temperature is 38°C, and the browning time is 50s.

[0065] According to the test, the copper loading capacity of the obtained browning solution can reach 58g / L, and the copper surface can obtain a uniform and rough surface after browning treatment, and has stable bonding force and excellent heat resistance with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com