Multi-layer core shell structure CeO2 nanometer hollow sphere template-free composite method

A technology of multi-layer core-shell structure and synthesis method, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of inability to control the number of core-shell structure layers, thickness control, high ligand cost, and low synthesis efficiency. , to achieve the effect of simple and efficient synthesis method, uniform distribution, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Synthesis of multilayer core-shell structure CeO 2 Nano Hollow Ball:

[0037] A multilayer core-shell structure CeO 2 A highly efficient template-free synthesis method for hollow nanospheres, comprising the following steps:

[0038] (1) 0.4mol Ce(NO 3 ) 3 ·6H 2 O and 1.2mol of pyridine-2,5-dicarboxylic acid were dissolved in a mixed solvent of 16ml of absolute ethanol and 16ml of dimethylamide to prepare Ce(NO 3 ) 3 solution;

[0039] (2) Put the above mixed solution in a reaction kettle, react at 160°C for 12h, centrifuge after the reaction (centrifugal speed is 1000 rpm, time is 5min), wash, and dry at 80°C to obtain a coordination polymer of cerium Nano solid ball;

[0040] (3) Place the above-mentioned cerium coordination polymer nanosolid spheres in a muffle furnace, calcinate at 600°C for 4h, and cool to room temperature to obtain a multilayer core-shell structure CeO 2 nano hollow spheres.

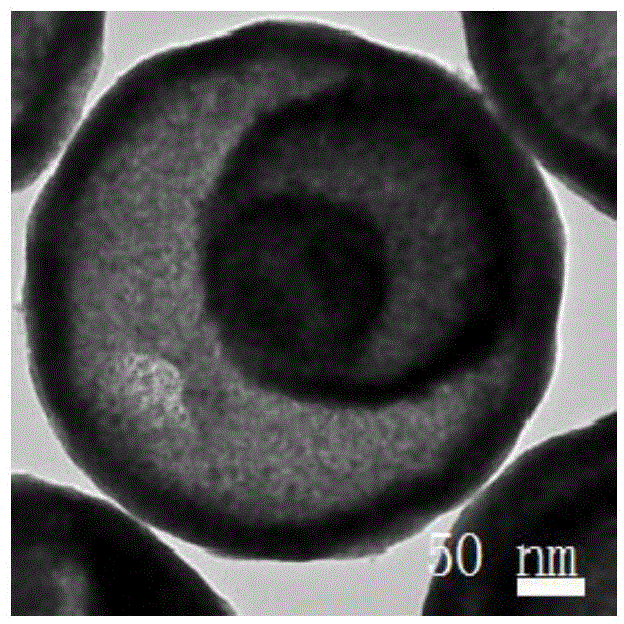

[0041] The resulting multilayer core-shell CeO ...

Embodiment 2

[0042] Embodiment 2: Synthesis of multilayer core-shell structure CeO 2 Nano Hollow Ball:

[0043] A multilayer core-shell structure CeO 2 A highly efficient template-free synthesis method for hollow nanospheres, comprising the following steps:

[0044] (1) 0.4mol Ce(NO 3 ) 3 ·6H 2 O and 1.2mol of pyridine-2,5-dicarboxylic acid were dissolved in a mixed solvent of 16ml of absolute ethanol and 16ml of dimethylamide to prepare Ce(NO 3 ) 3 solution;

[0045] (2) Put the above mixed solution in a reaction kettle, react at 160°C for 6h, centrifuge after the reaction (centrifugation speed is 1000 rpm, time is 5min), and dry at 80°C to obtain the coordination polymer of cerium Nano solid ball;

[0046] (3) Place the above-mentioned cerium coordination polymer nanosolid spheres in a muffle furnace, calcinate at 800°C for 4 hours, and cool to room temperature to obtain multilayer core-shell structure CeO 2 nano hollow spheres.

[0047] The resulting multilayer core-shell CeO ...

Embodiment 3

[0048] Example 3: Detection of the multilayer core-shell structure CeO prepared in Examples 1-2 2 Purity of hollow nanospheres:

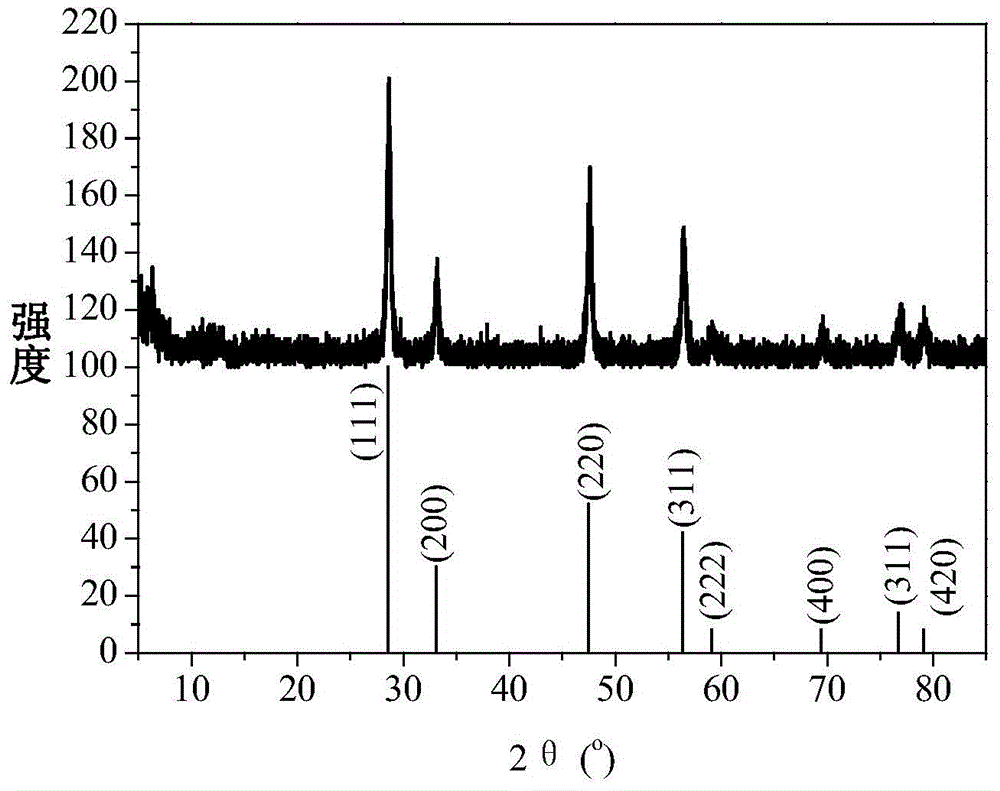

[0049] Using Rigaku / Max-3A X-ray diffractometer to measure the multilayer core-shell structure CeO prepared in Examples 1-2 2 Nano hollow spheres (CuKα radiation, ), the result is as figure 1 As shown, all the peaks of the hollow nanospheres correspond to the cubic phase of CeO 2 The standard card (JCPDS 34-0394) is completely consistent, indicating that the calcined coordination polymer is completely converted to CeO 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com