A special silicone adhesive for emi interface with high adhesion and high resilience

A high resilience and silicone technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problems of low rebound rate of glue, low bonding strength, heat resistance, etc. , to achieve good bonding effect, strong adhesion, excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Preparation of base paste:

[0049] At room temperature, weigh methyl vinyl polysiloxane resin, such as structural formula (1), where a=1.0, b=0.2, a+b=1.2, 20 parts, vinyl-terminated silicone oil, viscosity 10000mPa.S, 70 parts, fumed white carbon black TS530, 30 parts, 10 parts of dimethyldichlorosilane, kneaded at 120°C for 5h and took out, cooled to room temperature.

[0050] (2) Preparation of silicone adhesive:

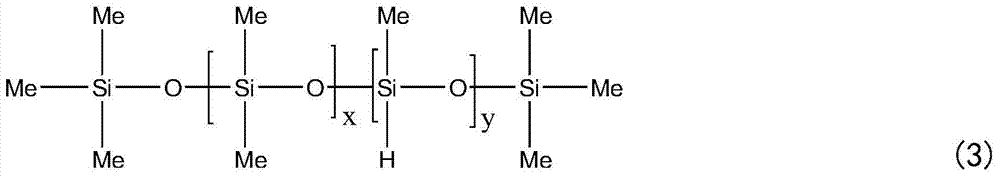

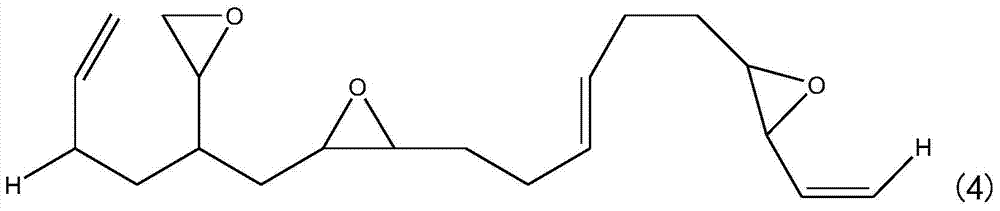

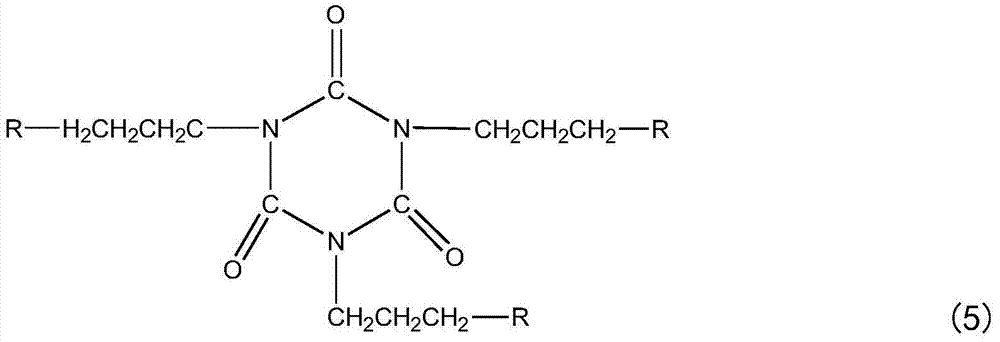

[0051] At room temperature, add 91.8 parts of base paste, crosslinking agent, structural formula such as (3), wherein x is 0, y is 30, 5 parts, rebound rate control agent, such as structural formula (4), 1 part, adhesion promotion agent, such as structural formula (5), wherein x is 4, y is 4, 1 part, heat stabilizer, such as structural formula (6), wherein m is 2, n is 2, 1 part, 3-methyl-1-butyl Add 0.1 part of alkyne-3-ol into the double planetary high-speed disperser one by one, stir well for 1 hour, pay attention to temperature control (the temp...

Embodiment 2

[0053] (1) Preparation of base paste:

[0054] At room temperature, weigh methyl vinyl polysiloxane resin, such as structural formula (2), wherein a=0.2, b=0.2, c=0.2, d=0.2, a+b+c+d=0.8, 10 parts, vinyl-terminated silicone oil, viscosity 100000mPa.S, 60 parts, fumed silica R974, 20 parts, 5 parts of octamethylcyclotetrasiloxane, knead at 120°C for 5h and take it out, cool to room temperature .

[0055](2) Preparation of silicone adhesive:

[0056] At room temperature, add 64 parts of base paste, crosslinking agent, structural formula such as (3), wherein x is 10, y is 10, 20 parts, rebound rate control agent, such as structural formula (4), 5 parts, adhesion promotion Agent, such as structural formula (5), wherein x is 10, y is 10, 5 parts, heat stabilizer, such as structural formula (6), wherein m is 6, n is 6, 5 parts, ethynyl cyclohexanol, 0.5 parts , in turn into the double planetary high-speed disperser, fully stirred for 1 hour, pay attention to temperature control (...

Embodiment 3

[0058] (1) Preparation of base paste:

[0059] At room temperature, weigh methyl vinyl polysiloxane resin, such as structural formula (1), wherein a=0.4, b=0.3, a+b=0.7, 7 parts, methyl vinyl polysiloxane resin , such as structural formula (2), where a=0.4, b=0.3, c=0.4, d=0.1, a+b+c+d=1.2, 7 parts, vinyl-terminated silicone oil, viscosity 50000mPa.S, 65 parts , Fumed silica R972, 25 parts, 7 parts of dimethyldichlorosilane, kneaded at 120°C for 5h and taken out, cooled to room temperature.

[0060] (2) Preparation of silicone adhesive:

[0061] At room temperature, add 74.4 parts of base paste, crosslinking agent, the structural formula is as (3), where x is 6, y is 20,, 8 parts, the hydrogen content of hydrogen-containing silicone resin is 0.8wt%, 8 parts, the rebound rate Control agent, such as structural formula (4), 3 parts, adhesion promoter, such as structural formula (5), wherein x is 6, y is 6, 3 parts, thermal stabilizer, such as structural formula (6), wherein m i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com