Method for carrying out treatment and regenerative cyclic utilization on semi-coke wastewater and recycling resources

A semi-coke waste water and resource recovery technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, general water supply conservation, etc., can solve problems such as insufficient treatment depth, achieve high activity, reduce consumption, and achieve The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

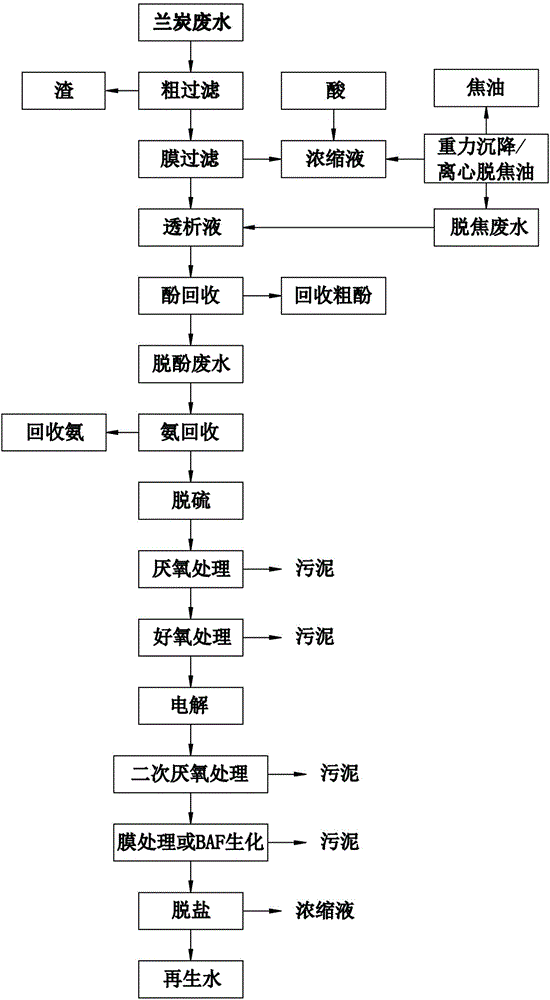

Method used

Image

Examples

Embodiment 1

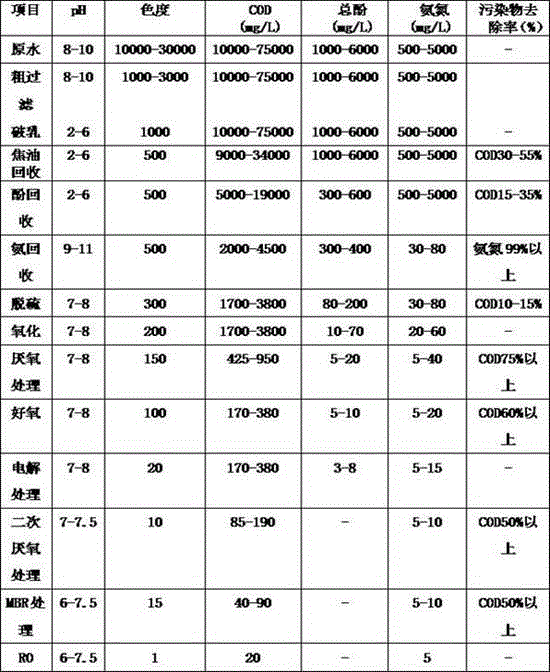

[0054] A semi-coke wastewater treatment regeneration recycling and resource comprehensive utilization method.

[0055] (1) Coarse filtration: Coarsely filter the semi-carbon wastewater with a COD of 10,000 mg / L, ammonia nitrogen of 500 mg / L, total phenols of 1,000 mg / L, a chroma of 10,000 times, and a pH value of 8 through a grid or screen. Remove large particles of debris.

[0056] (2) Membrane filtration: add acid to adjust the pH to 2-6 to the semi-coke wastewater that has been coarsely filtered to remove large particles, and then filter through the membrane to obtain a concentrated solution rich in coal tar and a dialysate that removes coal tar. The concentration ratio is 8 to 10.

[0057] The membrane filtration is ceramic membrane filtration; the pore diameter of the ceramic membrane element of the ceramic membrane filtration system is 50nm; the working pressure is 3-6bar, and the temperature is 15-55°C.

[0058] (3) Recovery of coal tar: The concentrated solution rich...

Embodiment 2

[0080] A semi-coke wastewater treatment regeneration recycling and resource comprehensive utilization method.

[0081] (1) Coarse filtration: Coarsely filter the semi-carbon wastewater with a COD of 75,000 mg / L, ammonia nitrogen of 5,000 mg / L, total phenols of 6,000 mg / L, a chroma of 30,000 times, and a pH of 10 through a grid or screen to remove Large particles of debris.

[0082] (2) Membrane filtration: add acid to adjust the pH to 2-6 to the semi-coke wastewater that has been coarsely filtered to remove large particles, and then filter through the membrane to obtain a concentrated solution rich in coal tar and a dialysate that removes coal tar. The concentration ratio is 3 times.

[0083] The membrane filtration is metal membrane filtration; the metal membrane element of the metal membrane filtration system has a pore size of 30-100nm; the working pressure is 3-6bar, and the temperature is 15-55°C.

[0084] (3) Coal tar recovery: centrifuge the concentrated solution rich...

Embodiment 3

[0108] A semi-coke wastewater treatment regeneration recycling and resource comprehensive utilization method.

[0109] (1) Coarse filtration: Coarsely filter the blue carbon wastewater with COD of 34967mg / L, ammonia nitrogen of 1911mg / L, total phenols of 6000mg / L, chroma of 2000 times, and pH value of 8.1 through a screen to remove large particles sundries.

[0110] (2) Membrane filtration: add acid to adjust the pH to 2-6 to the semi-coke wastewater that has been coarsely filtered to remove large particles, and then filter through the membrane to obtain a concentrated solution rich in coal tar and a dialysate that removes coal tar. The concentration ratio is 5 times.

[0111] The membrane filtration is one of ceramic membrane filtration or metal membrane filtration; the ceramic membrane element of the ceramic membrane filtration system has a pore size of 20-100 nm, a working pressure of 3-6 bar, and a temperature of 15-55°C.

[0112] (3) Coal tar recovery: The concentrated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com