Monodisperse nanosheets and/or nanorings and their preparation and application

A monodisperse, nanosheet technology, applied in the field of nanomaterials, can solve the problems of high cost, complex process, limitations, etc., and achieve the effects of low cost, good repeatability and adjustable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

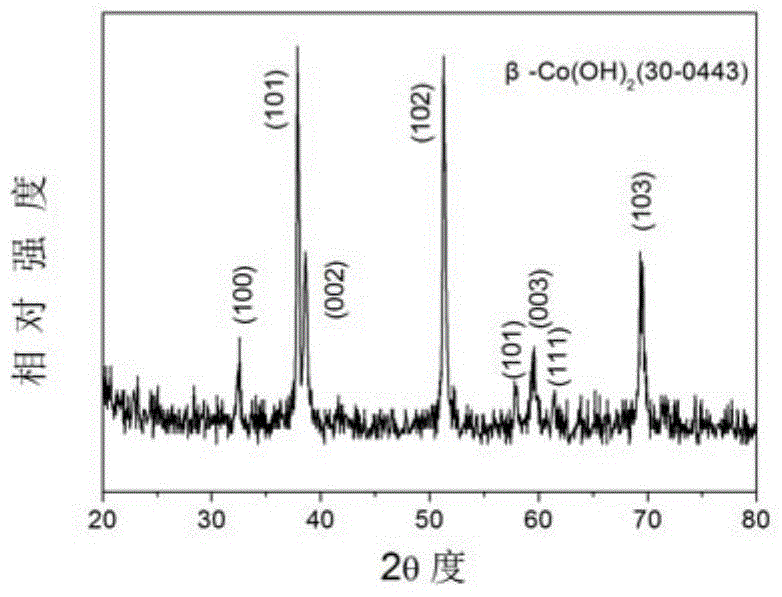

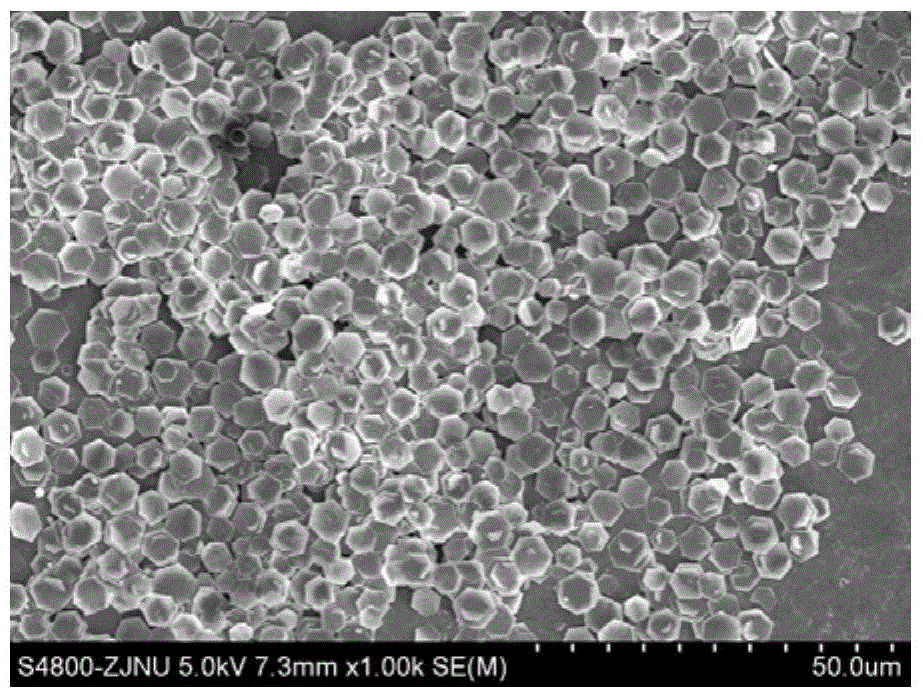

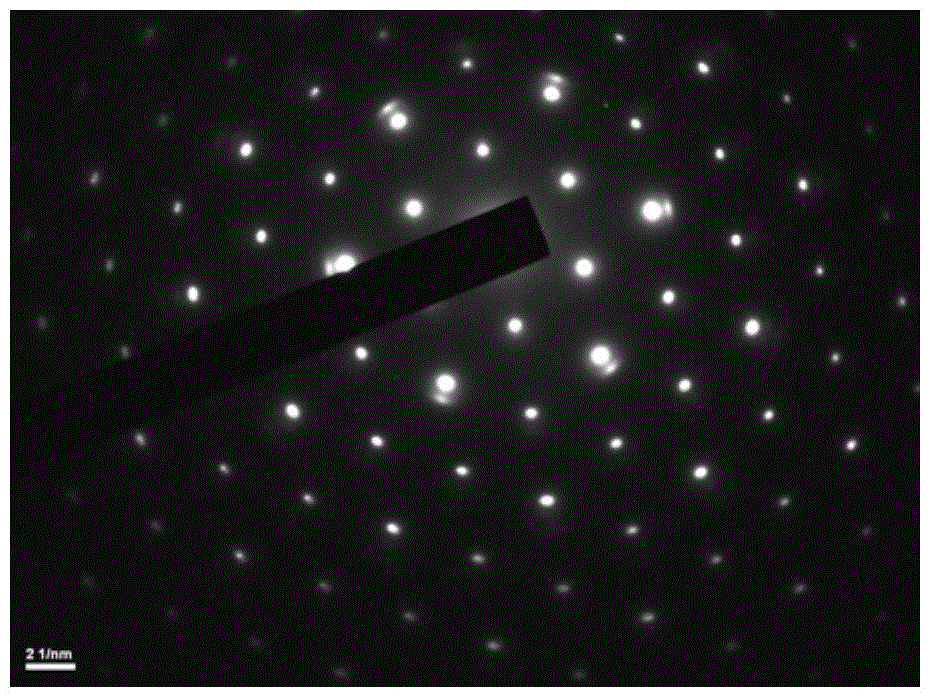

[0034] First mix 0.237g cobalt chloride hexahydrate (the amount of substance is 0.001mol, and the concentration is 5mM), 180mL distilled water, 20mL ethanol and 1.68g hexamethylenetetramine (the amount of substance is 0.012mol) [alkali and cobalt salt substance The ratio of the amount (referred to as alkali ratio) is 12:1] into a 400mL beaker, stirred for 10min, then put the beaker into an oil bath, reacted at 90°C for 1h, then cooled at room temperature, and finally washed, Filter and dry to obtain the monodisperse β-Co(OH) 2 Nanosheets. The resulting product is pink, and its phase and morphology, structure and selected area electron diffraction spectrum observed under a scanning electron microscope are as follows: Figure 1-3 shown. It can be seen that the product is a monodisperse regular hexagonal β-Co(OH) 2Nanosheets. The nano sheet has a single crystal structure, uniform size, clear edges and corners, and a side length of 1.51-3.27 μm.

Embodiment 2

[0036] The steps are the same as in Example 1, but the reaction temperature is 70°C. The resulting product is pink, and the morphology observed under the scanning electron microscope is as follows: Figure 4 As shown, it can be seen that the product is a monodisperse regular hexagonal β-Co(OH) 2 Nanosheets, uniform in size, rounded corners, side length 0.72-1.99 μm, thickness 0.12-0.26 μm.

Embodiment 3

[0038] The steps are the same as in Example 1, but the reaction temperature is 100°C. The resulting product is pink, and the morphology observed under the scanning electron microscope is as follows: Figure 5 As shown, it can be seen that most of the products are monodisperse regular hexagonal β-Co(OH) 2 Nanosheets, with clear borders, sharp edges and corners, and a side length of 1.0-1.92 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com