Silicon-containing polyimide copper-clad plate and preparation method thereof

The technology of silicon polyimide and silicon polyimide resin is applied in the field of silicon-containing polyimide copper clad laminate and its preparation, which can solve the problems of less than aromatic heterocyclic polymer systems, low heat resistance, It can not meet the problems of high temperature application and other problems, and achieve the effects of excellent electrical and mechanical properties, high temperature resistance and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

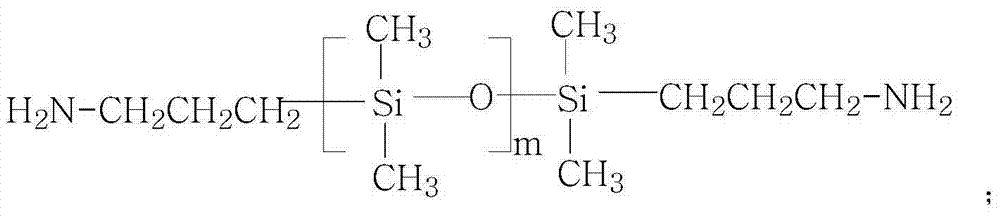

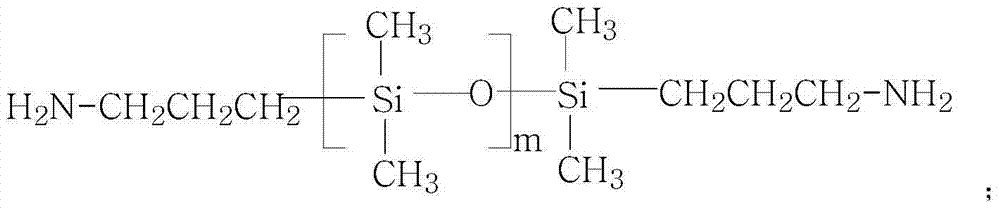

[0039] 988 grams (1 mole) of silicone diamine (average molecular weight is 988), 3500 grams of N-methyl-2- Pyril Rolidone and 600 grams of tetrahydrofuran were put into the reaction kettle, after stirring and dissolving at room temperature, 1041 grams (2 moles) of 2,2-bis[4-(3,4-dicarboxyphenoxy)phenyl]propanedianhydride were added , stirred and reacted at room temperature for 2 hours, added 800 grams of toluene, heated to reflux and separated water for 3 hours to obtain 6929 grams of component A, which was designated as A-1.

Embodiment 2

[0041] 1284 grams (1 mole) of silicone diamine (average molecular weight is 1284), 3700 grams of N-methyl-2- Pyril Rolidone and 4000 grams of methyl tetrahydrofuran were put into the reaction kettle, and after stirring and dissolving at room temperature, 558.4 grams (1.8 moles) of 3,3',4,4'-tetracarboxydiphenyl ether dianhydride and 104.1 grams (0.2 moles ) 2,2-bis[4-(3,4-dicarboxyphenoxy)phenyl]propane dianhydride, stirred and reacted at room temperature for 1 hour, added 770 grams of toluene, heated and refluxed for 5 hours to separate water, and obtained 10416.5 grams A component, denoted as A-2.

Embodiment 3

[0043] 584 grams (2 moles) of 1,3-bis(3-aminophenoxy)benzene, 4000 grams of N,N-dimethylacetamide and 1850 grams of N-methyl-2- Pyril Put rolidone into the reaction kettle, stir and dissolve at room temperature, cool to below 1°C, add 558.4 grams (1.8 moles) of 3,3',4,4'-tetracarboxydiphenyl ether dianhydride and 29.4 grams (0.3 mol) maleic anhydride, stirred and reacted at 1° C. for 2 hours to obtain 7021.8 grams of component B, denoted as B-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com