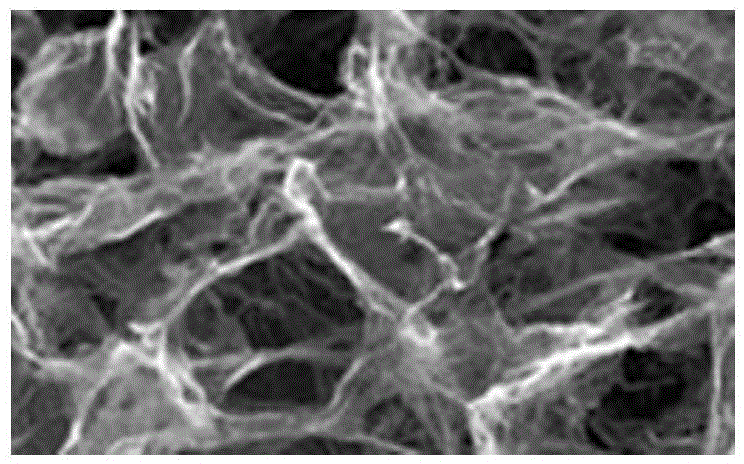

3D nitrogen-doped graphene/molybdenum disulfide compound and preparation method thereof

A nitrogen-doped graphene, molybdenum disulfide technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, multiple hybrid/electric double layer capacitors, etc. Porous structure, large mass transfer resistance and other problems, to achieve the effects of improved electrochemical activity, superior rate performance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Improved Hummer method to prepare graphene oxide (GO): First, add 2.5g of expanded graphite and 5g of sodium nitrate in a 500mL beaker, then, add 120mL of concentrated sulfuric acid with a mass concentration of 98% to it, and place the resulting mixture in an ice bath Stirring under the conditions for 120min; secondly, under the condition of strong stirring, slowly add 15g of potassium permanganate to the obtained mixture for reaction, the temperature of the reaction is controlled below 20°C, and the potassium permanganate is removed after adding Ice bath equipment, stir the obtained reaction product at room temperature overnight; then, under vigorous stirring, add 150mL of secondary water dropwise to the beaker, the reaction temperature rises rapidly to 98°C, foam can be observed, and the beaker The color of the reaction product turns yellow, and the reaction product is stirred at 98° C. for 2 h, and 50 mL of hydrogen peroxide with a mass concentration of 30% is added t...

Embodiment 2

[0051] After preparing graphene oxide (GO) with the same method as in Example 1, get 100 mg of pre-prepared GO and disperse it in 100 mL of aqueous solution (mass volume ratio is 1:1), after ultrasonic stirring for 30 min, add 1.0 g of calcium chloride and 0.82g of oxalic acid powder, 1.0g of thioacetamide and 0.32g of sodium molybdate were dissolved in 50ml of secondary water at the same time, ultrasonicated for 30min, and the two solutions were mixed, ultrasonicated for 2h. When transferred to a 1000W induction cooker and heated to 80°C, NaOH (0.5mol L -1 ) adjust the pH of the solution to 11, while continuing to heat, after reacting for 8 hours, take the precipitate, wash it several times with secondary water, and dry it in vacuum at 60°C for 24 hours to obtain nitrogen-doped graphene / molybdenum disulfide / calcium oxalate composite thing. Dissolve the prepared nitrogen-doped graphene / molybdenum disulfide / calcium oxalate in 5mol L -1 Hydrochloric acid aqueous solution, ultr...

Embodiment 3

[0053] After preparing graphene oxide (GO) with the same method as in Example 1, get 100 mg of pre-prepared GO and disperse it in 100 mL of aqueous solution (mass volume ratio is 1:1), after ultrasonic stirring for 30 min, add 0.5 g of calcium chloride and 0.41g of oxalic acid powder, 1.0g of thioacetamide and 0.96g of sodium molybdate were dissolved in 50ml of secondary water at the same time, sonicated for 30min, and the two solutions were mixed and sonicated for 2h. When transferred to a 1300W induction cooker and heated to 80°C, ammonia solution (0.1mol L -1 ) adjust the pH of the solution to 10, while continuing to heat, after reacting for 6 hours, take the precipitate, wash it several times with secondary water, and freeze-dry it at -30°C for 24 hours to obtain nitrogen-doped graphene / molybdenum disulfide / calcium oxalate Complex. Dissolve the prepared nitrogen-doped graphene / molybdenum disulfide / calcium oxalate in 5mol L -1 Hydrochloric acid aqueous solution, ultrasoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com