A connection method of integrated prefabrication of concrete shear wall and filling wall

A technology of concrete shear wall and connection method, applied in the field of construction, can solve the problems of damage to the quality of the house, unable to resist cracking, affecting the wall, etc., and achieve the effects of excellent quality of finished products, saving material consumption, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

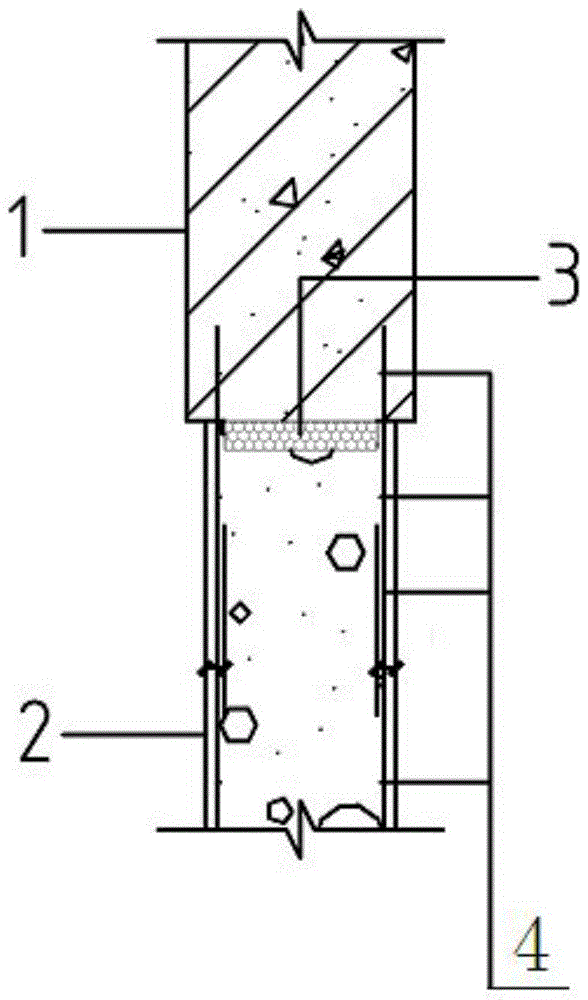

[0028] The integrated prefabricated connection method of the concrete shear wall and the filling wall comprises the following steps:

[0029] Step 1. Formwork is performed on the prefabricated concrete shear wall 1 and the prefabricated infill wall 2 according to the construction design requirements.

[0030] Step 2: After the form work is completed, enter the program of binding steel bars.

[0031] Bind the steel bars of the prefabricated concrete shear wall 1 and the steel wires 4 of the prefabricated filling wall, and extend the steel wires 4 of the prefabricated filling wall 50mm into the interior of the prefabricated concrete shear wall 1 .

[0032] Step 3, if the prefabricated concrete shear wall 1 or the prefabricated infill wall 2 is a hollow structure, insert the mold corresponding to it;

[0033] If the prefabricated concrete shear wall 1 or the prefabricated infill wall 2 is a solid structure, go directly to step 4.

[0034] Step 4: Place and fix the soft material...

Embodiment 2

[0039] The integrated prefabricated connection method of the concrete shear wall and the filling wall comprises the following steps:

[0040] Step 1. Formwork is performed on the prefabricated concrete shear wall 1 and the prefabricated infill wall 2 according to the construction design requirements.

[0041] Step 2: After the form work is completed, enter the program of binding steel bars.

[0042] The steel bars of the prefabricated concrete shear wall 1 and the steel wires 4 of the prefabricated filling wall are bound, and the steel wires 4 of the prefabricated filling wall are extended into the interior of the prefabricated concrete shear wall 1 by 100 mm.

[0043] Step 3, if the prefabricated concrete shear wall 1 or the prefabricated infill wall 2 is a hollow structure, insert the mold corresponding to it;

[0044] If the prefabricated concrete shear wall 1 or the prefabricated infill wall 2 is a solid structure, go directly to step 4.

[0045] Step 4: Place and fix th...

Embodiment 3

[0050] The integrated prefabricated connection method of the concrete shear wall and the filling wall comprises the following steps:

[0051] Step 1. Formwork is performed on the prefabricated concrete shear wall 1 and the prefabricated infill wall 2 according to the construction design requirements.

[0052] Step 2: After the form work is completed, enter the program of binding steel bars.

[0053] Bind the steel bars of the prefabricated concrete shear wall 1 and the steel wires 4 of the prefabricated filling wall, and extend the steel wires 4 of the prefabricated filling wall 200mm into the interior of the prefabricated concrete shear wall 1 .

[0054] Step 3, if the prefabricated concrete shear wall 1 or the prefabricated infill wall 2 is a hollow structure, insert the mold corresponding to it;

[0055] If the prefabricated concrete shear wall 1 or the prefabricated infill wall 2 is a solid structure, go directly to step 4.

[0056] Step 4: Place and fix the soft material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com