Efficient production method of gamma-aminobutyric acid

A double arginine and glutamic acid decarboxylase technology, which is applied in the field of efficient production of γ-aminobutyric acid, can solve problems such as the difficulty of correct folding and effectively carry out, and achieve the effect of reducing the cost of separation and purification and simplifying the separation and purification procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The construction of embodiment 1 recombinant bacteria

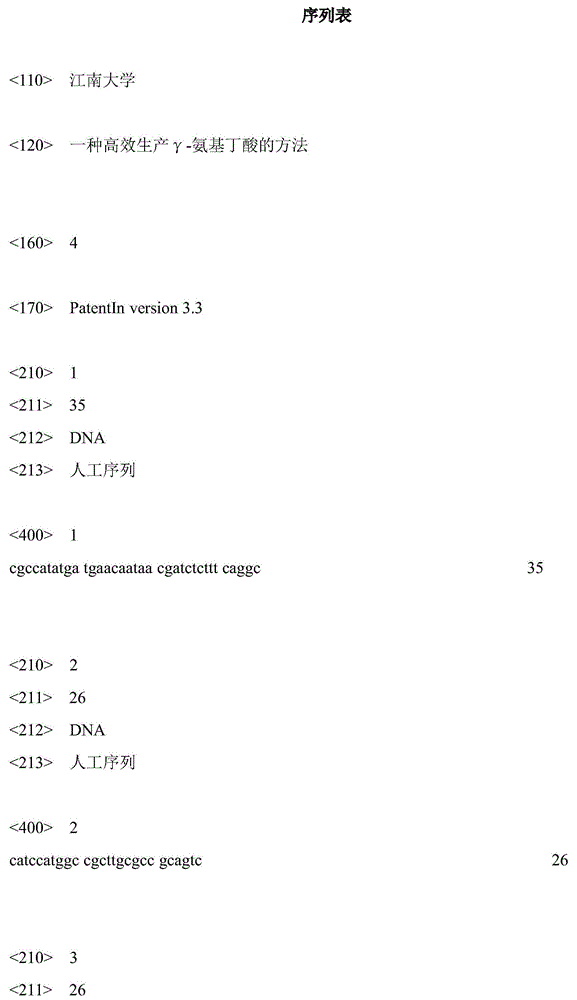

[0022] 1) Genomic DNA was extracted from Escherichia coli E.coli w3110 as a template for PCR amplification, and the primer for amplifying the signal peptide torA gene was: 5'-CGC CATATG ATGAACAATAACGATCTCTTTCAGGC-3' and 5'-CAT CCATGG CCGCTTGCGCCGCAGTC-3', the primer for amplifying the glutamic acid decarboxylase gene gadB is: 5'-CAT CCATGG ATAAGAAGCAAGTAACG-3' and 5'-CC CTCGAG TCAGGTATGTTTAAAAGCTGTT-3'.

[0023] 2) Digest the PCR product of the torA gene with restriction endonucleases NdeI and NcoI, digest the PCR product of the gadB gene with restriction endonucleases NcoI and XhoI, and treat the vector pET20b(+) with NdeI and XhoI. After the digestion product was purified, T4 ligase was ligated overnight at 22 degrees Celsius, transformed into E.coli JM109, and the correct transformant was screened. For the obtained correct transformant, extract the plasmid and transform E.coli BL21(DE3)

Embodiment 2

[0024] Example 2 The extracellular glutamic acid decarboxylase SDS-PAGE and glutamic acid decarboxylase enzyme activity detection of recombinant bacteria at shake flask level

[0025] 1) Shake flask horizontal fermentation of recombinant bacteria

[0026] a) Medium: The seed medium is LB medium (1L): tryptone 10g, yeast extract 5g, NaCl10g, pH adjusted to 7.0; fermentation medium is TB medium (1L): tryptone 12g, yeast extract Extract 24g, Glycerin 5g, K 2 HPO 4 14.6g, NaH 2 PO 4 2H 2 O3.6g, glycine 7.5g, NaCl5g.

[0027] b) Cultivation method: The seeds cultured overnight at 37° C. and 200 rpm were transferred to TB medium at an inoculum size of 5%, and cultivated at 37° C. and 200 rpm for 36 hours.

[0028] c) Induction condition: Induce OD 600 The value is 1.0 and the IPTG concentration is 0.7 mM.

[0029] 2) SDS-PAGE checks the expression of glutamic acid decarboxylase in the cell and outside the cell, with empty load as the control ( figure 1 Among them, 1 and 2 ...

Embodiment 3

[0031] Embodiment 3 Recombinant bacteria fermenter horizontal fermentation

[0032]1) The seed medium is LB medium (1L): tryptone 10g, yeast extract 5g, NaCl10g, pH adjusted to 7.0; fermentation medium is TB medium (1L): tryptone 30g, yeast extract 20g , glycerol 8g, Na 2 SO 4 2.0g, (NH 4 ) 2 SO 4 2.5g, (NH 4 ) 2 -H-citrate1.0g,K 2 HPO 4 14.6g,NaH 2 PO 4 2H 2 O3.6g, MgSO 4 ·7H 2 O2.0g, thiamine100mg; feed medium (1L): yeast extract 50g, yeast extract 50g, glycerin 500g, MgSO 4 ·7H 2 O3.4g; induction (1L): lactose 200g.

[0033] 2) Culture method: when the initial glycerol in the medium is exhausted, that is, when the dissolved oxygen in the fermenter rises, grow at a specific growth rate of 0.12h -1 Exponential flow plus feed medium; to be OD 600 When it reached 50, the feeding medium was changed from exponential feeding to constant feeding, with a flow acceleration rate of 12mL / h, and lactose was fed at a speed of 0.8g / L / h for induction, and the induction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com