Solvothermal method for preparing three-dimensional nanometer layered structure WS2 and electrochemical application thereof

A layered structure, three-dimensional nanotechnology, applied in inorganic chemistry, nanotechnology, structural parts, etc., can solve the problems of ultra-high temperature hydrothermal danger, high reaction energy consumption, harsh conditions, etc., to achieve uniform morphology and no phase. Impurities, effects of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

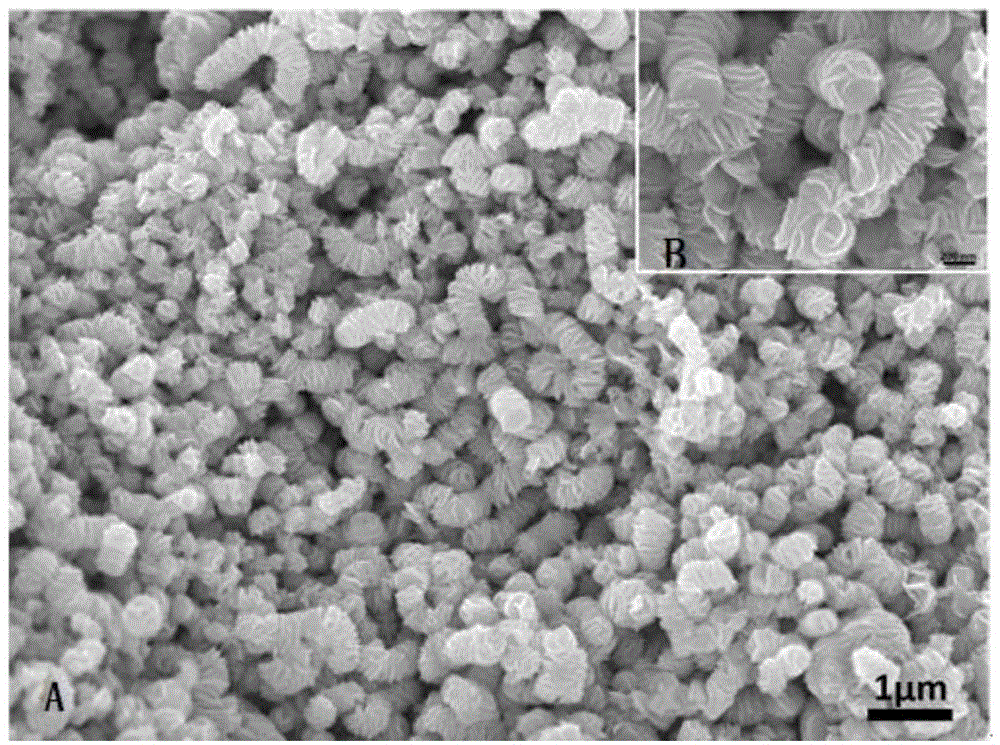

[0029] Example 1 Preparation of three-dimensional nano-layered structure WS 2

[0030] The three-dimensional nanolayer structure prepared by solvothermal synthesis is as follows:

[0031] (1) Weigh 125mg of tungstic acid and 70mg of S powder and disperse in the mixed solution of octylamine and n-hexanol, stir vigorously at room temperature for 30min, and the mixing ratio of octylamine and n-hexanol is 7:1;

[0032] (2) Transfer the above solution into the liner of a polytetrafluoroethylene reactor, put it into a stainless steel shell, tighten it, and react in a constant temperature oven at 200°C for 24 hours;

[0033] (3) After cooling to room temperature, the product was collected by filtration, washed three times with ethanol and deionized water, and the obtained powder was vacuum-dried at 80°C for 12 hours;

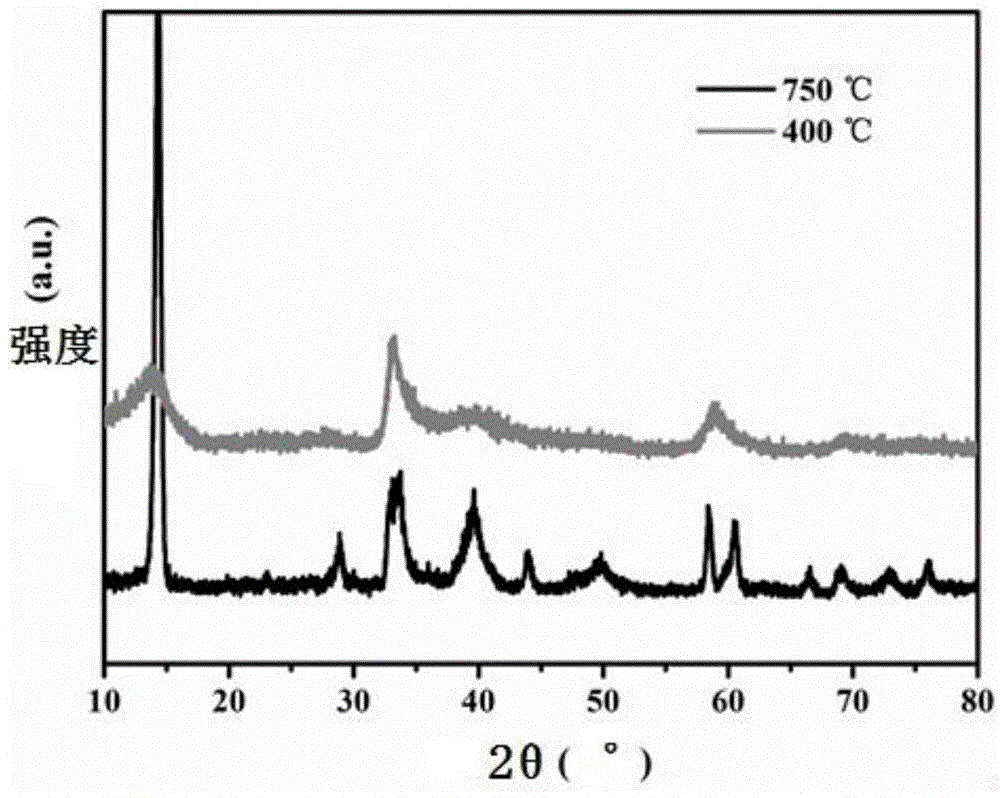

[0034] (4) The dried samples were heat-treated at 400°C and 750°C for 2 hours in a nitrogen atmosphere, and cooled to obtain a three-dimensional nano-layered structu...

Embodiment 2 3

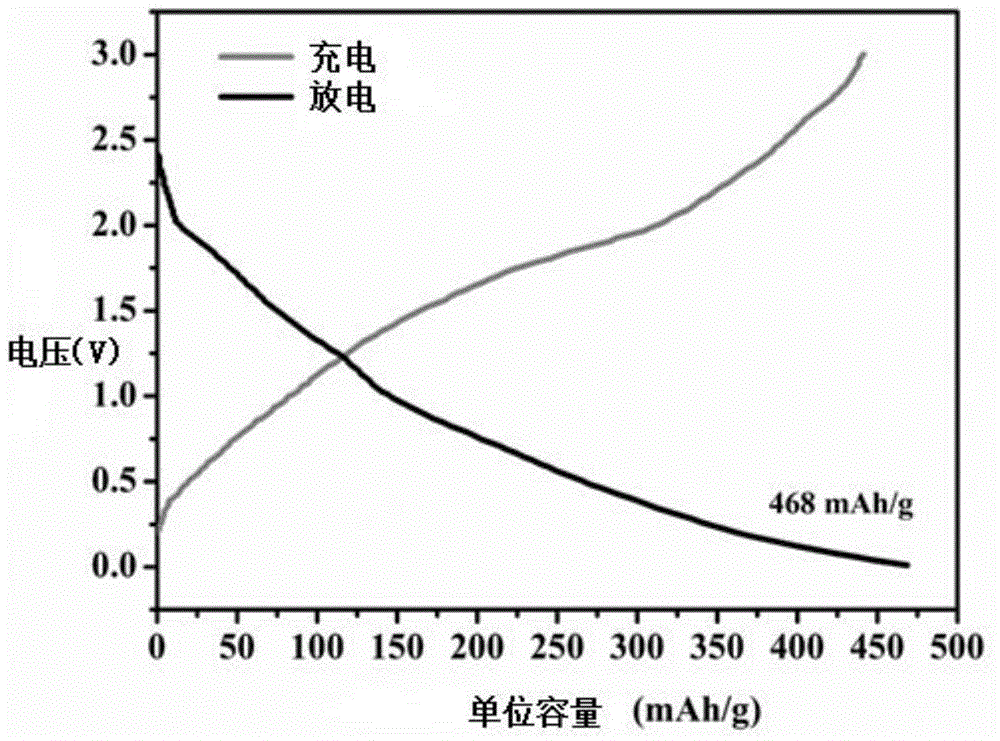

[0037] Example 2 Three-dimensional nano-layered structure WS 2 Applied to Li-ion battery and performance testing

[0038] Li-ion battery assembly and performance testing:

[0039] (1) Positive electrode preparation: The resulting product is mixed with conductive acetylene black and binder PVDF (polyvinylidene fluoride) in a mass ratio (70:20:10), and a certain amount of 1-methyl-2-pyrrolidone ( NMP), fully ground into a paste, evenly spread it on a copper foil with a diameter of 14 mm and a thickness of about 9 μm, then vacuum-dry at 120 ° C for 12 hours, after cooling, take it out for use;

[0040] (2) Battery assembly: Transfer the electrode sheet from the previous step to a glove box filled with argon gas, use a CR2025 button battery case, a metal lithium sheet with a diameter of 16mm as the negative electrode of the counter electrode, and a Celgard 2325 polypropylene film as a diaphragm, dissolve the 1mol / LLiPF 6 A mixture of ethylene carbonate (EC) and diethyl carbonat...

Embodiment 3

[0044] Example 3 Three-dimensional nano-layered structure WS 2 Application in electrocatalytic hydrogen evolution reaction

[0045] Electrode preparation and performance test for electrocatalytic hydrogen evolution reaction:

[0046] (1) Electrode preparation: take 1 mg of WS obtained in Example 1 2 The product, 0.5mg conductive carbon black, and 5ug Nafion aqueous solution (5wt%) are dispersed in 0.2ml water and ethanol mixture (volume ratio 1:1), and ultrasonicated for at least 30min until dispersed into a homogeneous solution. Then, 5 μg of the above solution was dropped on a glassy carbon electrode with a diameter of 3 mm, and dried in the air for measurement.

[0047] Hydrogen evolution reaction test: the polarization curve was carried out on the electrochemical workstation (CHI) test system using a three-electrode system. Step (1) prepare electrode, saturated calomel electrode and platinum wire as working electrode, reference electrode and counter electrode respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com