Preparation method for wheat bran dietary fiber

A technology for dietary fiber and wheat bran, which is applied in the field of food processing, can solve problems such as low phytic acid content, and achieve the effects of avoiding environmental pollution, increasing content and improving comprehensive utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

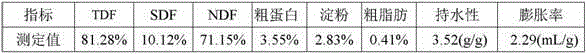

Embodiment 1

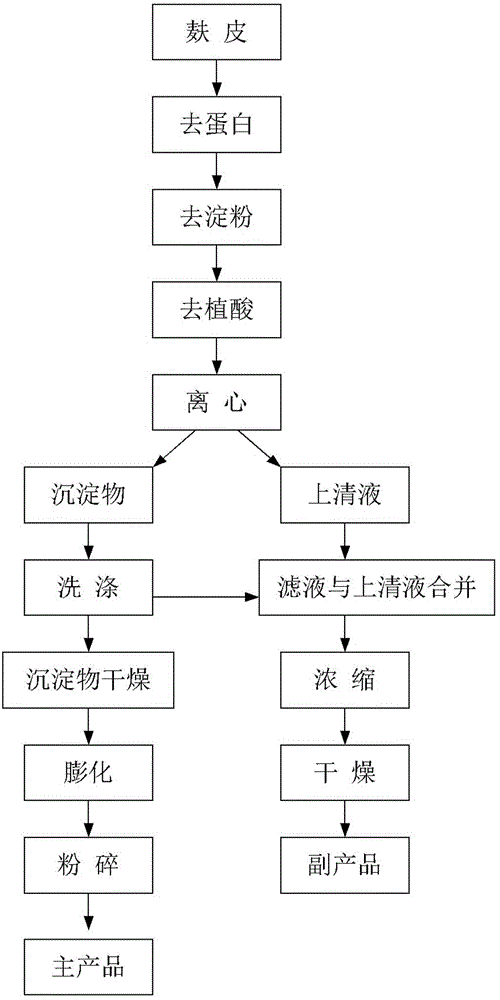

[0026] A preparation method of wheat bran dietary fiber, comprising the following steps:

[0027] (1) Crush (no impurities, no mildew, no oxidative rancidity) bran (see Table 1) and pass through a 40-mesh sieve, add water at 50°C according to the weight ratio of material to water 1:10, soak for 45 minutes, and use a colloid mill Refining so that the material can pass through a 70-mesh sieve;

[0028] (2) Use 1mol / L NaOH solution to adjust the pH of the material to 8.0, then add alkaline protease at 0.6% of the dry weight of the bran, and react for 2.5 hours under stirring conditions;

[0029] (3) Heat the material to 70°C, add medium-temperature α-amylase at 0.1% of the dry weight of the bran under stirring conditions, and react for 50 minutes;

[0030] (4) Cool the material to 50°C, add phytase at 0.6% of the dry weight of the bran, and react for 2.5 hours under stirring;

[0031] (5) The material is vacuum filtered, and the filter residue is filtered and washed with water ...

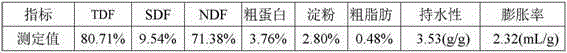

Embodiment 2

[0041] A preparation method of wheat bran dietary fiber, comprising the following steps:

[0042] (1) Grind (no impurities, no mildew, no oxidative rancidity) bran (see Table 1) and pass through a 40-mesh sieve, add water at 55°C according to the weight ratio of material to water 1:6, soak for 60 minutes, and use a colloid mill Refining so that the material can pass through an 80-mesh sieve;

[0043] (2) Use 1mol / L NaOH solution to adjust the pH of the material to 7.5, then add alkaline protease at 0.1% of the dry weight of the bran, and react for 3.0 hours under stirring conditions;

[0044](3) Heat the material to 65°C, add medium-temperature α-amylase at 0.01% of the dry weight of the bran under stirring conditions, and react for 80 minutes;

[0045] (4) Cool the material to 55°C, add phytase at 0.2% of the dry weight of the bran, and react for 3.0 hours under stirring;

[0046] (5) The material is vacuum filtered, and the filter residue is filtered and washed with clear ...

Embodiment 3

[0053] A preparation method of wheat bran dietary fiber, comprising the following steps:

[0054] (1) Crush (no impurities, no mildew, no oxidative rancidity) bran (see Table 1) and pass through a 40-mesh sieve, add water at 45°C according to the weight ratio of material to water 1:15, soak for 30 minutes, and use a colloid mill Refining so that the material can pass through a 60-mesh sieve;

[0055] (2) Use 1mol / L NaOH solution to adjust the pH of the material to 9.0, then add alkaline protease according to 1.0% of the dry weight of the bran, and react for 2.0h under stirring conditions;

[0056] (3) Heat the material to 75°C, add medium-temperature α-amylase at 0.2% of the dry weight of the bran under stirring conditions, and react for 30 minutes;

[0057] (4) Cool the material to 45°C, add phytase at 1.0% of the dry weight of the bran, and react for 2.0 hours under stirring;

[0058] (5) The material is vacuum filtered, and the filter residue is filtered and washed with c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com