Method for preparing nitrogen aluminum co-doping p type zinc oxide thin film

A zinc oxide film, co-doping technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problem of reducing film hole carrier concentration and mobility, unfavorable p-type zinc oxide film Application, poor crystallinity of the precursor film, etc., to achieve the effect of good crystalline state and optical properties of the film, increasing concentration and mobility, and optimizing sputtering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

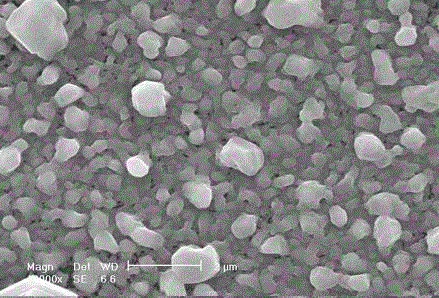

[0031] In this embodiment, an aluminum-nitrogen co-doped p-type zinc oxide thin film is prepared on a quartz glass substrate.

[0032] S1. Prepare the precursor: the substrate is made of quartz glass, soaked in acetone, absolute ethanol and deionized water in sequence, cleaned by ultrasonic waves, and dried with compressed air for later use; high-purity zinc with a purity of 99.999% is used as the target material. Place high-purity aluminum sheets of different areas on the target surface, control the content of aluminum in the sample to 2%, place a substrate above the target, and the distance between the substrate and the target is 5 cm, and the reaction chamber is vacuum pumped to 10 -4 Pa, the substrate temperature is set to 100°C, the RF source frequency is 12.56MHz, the input power is 160W, the working gas is nitrogen (99.999%) and argon (99.999%); before reactive sputtering, rotate the baffle to cover the substrate Bottom, use argon plasma to clean the pollutants on the ...

Embodiment 2

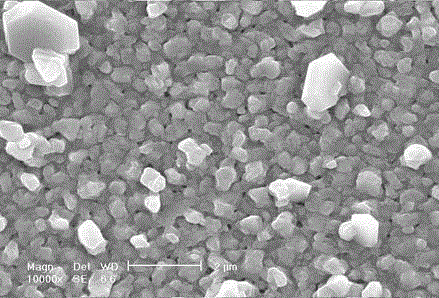

[0036] In this embodiment, an aluminum-nitrogen co-doped p-type zinc oxide thin film is prepared on a single crystal silicon wafer substrate.

[0037] S1. Preparation of precursor: the substrate is made of single crystal silicon wafer, which is soaked in acetone, absolute ethanol and deionized water in sequence, cleaned by ultrasonic waves, and dried with compressed air for later use; high-purity zinc with a purity of 99.999% is used as the target material, Place high-purity aluminum sheets of different areas on the target surface, control the content of aluminum in the sample to 2.5%, place a substrate above the target, and the distance between the substrate and the target is 7cm, and the reaction chamber has a background vacuum draw up to 10 -4 Pa, the substrate temperature is set to 150°C, the RF source frequency is 12.56MHz, the input power is 120W, the working gas is nitrogen (99.999%) and argon (99.999%); before reactive sputtering, rotate the baffle to cover the substr...

Embodiment 3

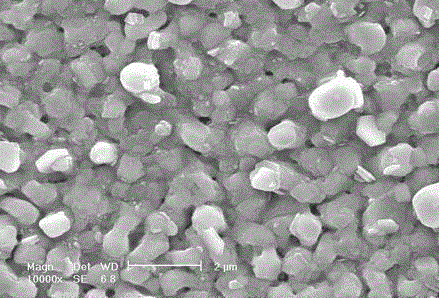

[0041] In this embodiment, an aluminum-nitrogen co-doped p-type zinc oxide thin film is prepared on a single crystal zinc oxide substrate.

[0042] S1. Preparation of precursor: the substrate is made of single crystal zinc oxide, soaked in acetone, absolute ethanol and deionized water in sequence, cleaned by ultrasonic waves, and dried with compressed air for later use; high-purity zinc with a purity of 99.999% is used as the target material , place high-purity aluminum sheets of different areas on the target surface, control the content of aluminum in the sample to be 3%, place a substrate above the target, the distance between the substrate and the target is 6cm, and the background of the reaction chamber Vacuum down to 10 -4 Pa, the substrate temperature is set to 200°C, the RF source frequency is 12.56MHz, the input power is 140W, the working gas is nitrogen (99.999%) and argon (99.999%); before reactive sputtering, rotate the baffle to cover the substrate Bottom, use ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Optical bandgap | aaaaa | aaaaa |

| Optical bandgap | aaaaa | aaaaa |

| Optical bandgap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com