Automobile bumper

A technology for automobile bumpers and bumpers, which is applied in the field of auto parts materials, can solve the problems of small elongation at break, insufficient impact strength, and low thermal deformation temperature, and achieve hardness and melt flow rate improvement, resistance Effects of improved chemical properties and high heat deflection temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

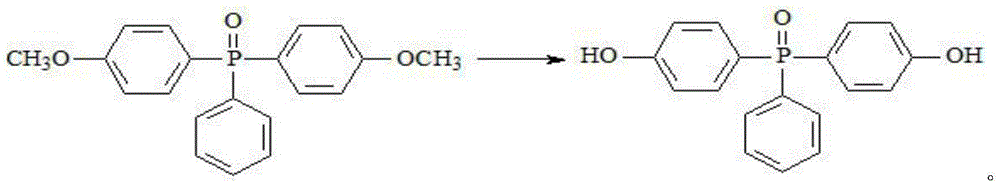

[0015] The bumper material includes the following components in parts by weight: 45 parts polypropylene, 8 parts bis(p-hydroxyphenyl)phenyl phosphine oxide, 10 parts thermoplastic polyurethane, 7 parts ultrafine magnesium hydroxide, 8 parts polyamide , 1-6 parts of acrylonitrile-butadiene-styrene, 6 parts of ethylene propylene rubber, 6 parts of polyethylene, 7 parts of shear thickening fluid, 14 parts of polymetaphenylene isophthalamide fiber, 3 parts Antistatic agent, 3 parts antioxidant, 6 parts dispersant, 3 parts plasticizer, 3 parts UV absorber.

[0016] In this embodiment, the antistatic agent is ethoxylauramide in ethoxylated alkylamine.

[0017] In this embodiment, the antioxidant is a mixture of dilauryl thiodipropionate and tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester. In the example, replace dilauryl thiodipropionate with one of dilauryl thiodipropionate, lauryl thiodipropionate, and didodecyl thiodipropionate in equal parts by weigh...

Embodiment 2

[0024] The bumper material includes the following components in parts by weight: 35 parts polypropylene, 2 parts bis(p-hydroxyphenyl)phenyl phosphine oxide, 5 parts thermoplastic polyurethane, 2 parts ultrafine magnesium hydroxide, 4 parts polyamide , 1 part of acrylonitrile-butadiene-styrene, 3 parts of ethylene propylene rubber, 3 parts of polyethylene, 4 parts of shear thickening fluid, 10 parts of poly(metaphenylene isophthalamide) fiber, 1 part of antistatic Agent, 1 part antioxidant, 4 parts dispersant, 1 part plasticizer, 1-5 parts stabilizer;

[0025] In this embodiment, the antistatic agent is glycerol monostearate (GMS).

[0026] In this embodiment, the antioxidant is a mixture of dilauryl thiodipropionate and tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester. In the example, replace dilauryl thiodipropionate with one of dilauryl thiodipropionate, lauryl thiodipropionate, and didodecyl thiodipropionate in equal parts by weight. Species, or...

Embodiment 3

[0033] The bumper material includes the following components in parts by weight: 55 parts of polypropylene, 10 parts of bis(p-hydroxyphenyl)phenyl phosphine oxide, 15 parts of thermoplastic polyurethane, 10 parts of ultrafine magnesium hydroxide, 12 parts of polyamide , 6 parts of acrylonitrile-butadiene-styrene, 11 parts of ethylene propylene rubber, 11 parts of polyethylene, 10 parts of shear thickening fluid, 16 parts of polymetaphenylene isophthalamide fiber, 6 parts of antistatic Agent, 4 parts antioxidant, 10 parts dispersant, 5 parts plasticizer, 5 parts stabilizer.

[0034] In this embodiment, the antistatic agent is an ethoxylated alkylamine.

[0035] In this embodiment, the antioxidant is a mixture of didodecyl thiodipropionate and tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol, In this example, according to the same parts by weight, the dilauryl thiodipropionate was replaced with dilauryl thiodipropionate, dilauryl thiodipropionate, and lauryl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com