Nanocellulose surface-modified core-shell structure fire retardant, and preparation method and application of fire retardant

A nanocellulose and surface modification technology, applied in the field of flame retardant materials, can solve the problems of weakening the flame retardant performance of intumescent flame retardants, insufficient carbon source of intumescent flame retardants, and great influence on the mechanical properties of materials, etc. Good flame retardant properties, increased contact area, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

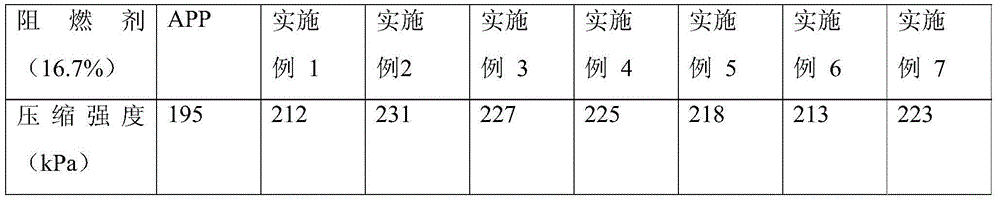

Embodiment 1

[0028] Prepare the nanocellulose surface modified core-shell structure flame retardant according to the following steps:

[0029] (1) Add 5.00 g of melamine and 9.00 mL of 37% formaldehyde solution at room temperature to a three-necked flask containing 50.00 mL of deionized water, dropwise add potassium hydroxide solution to adjust the pH to 8-9, stir and heat up After reaching 70°C, keep stirring and heat-preserve for 40 minutes. After the reaction is complete, an emulsified liquid is obtained, which is cooled to room temperature; the cooled emulsified liquid is added to a flask containing 60.00 g of APP, and 80.00 mL of ethanol solution is added to stir, drop Add acetic acid solution to adjust the pH value to 3-4, slowly heat to 60°C, keep warm at this temperature for 1 hour, then stir to cool down, filter with suction, wash, dry, and finally get a white powder;

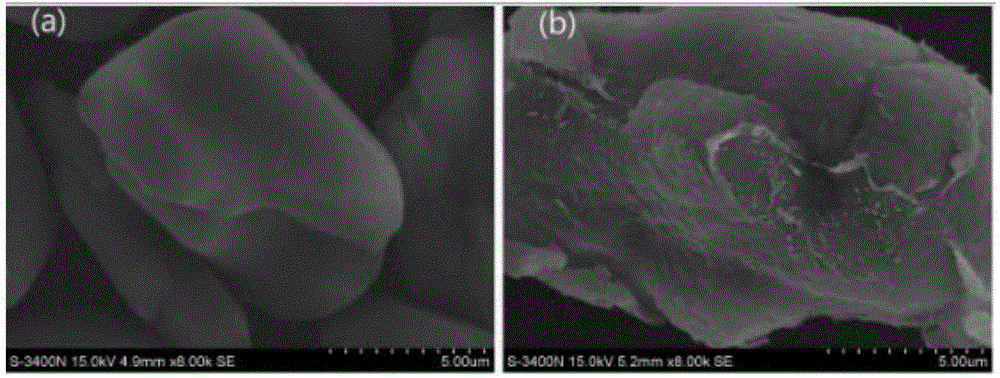

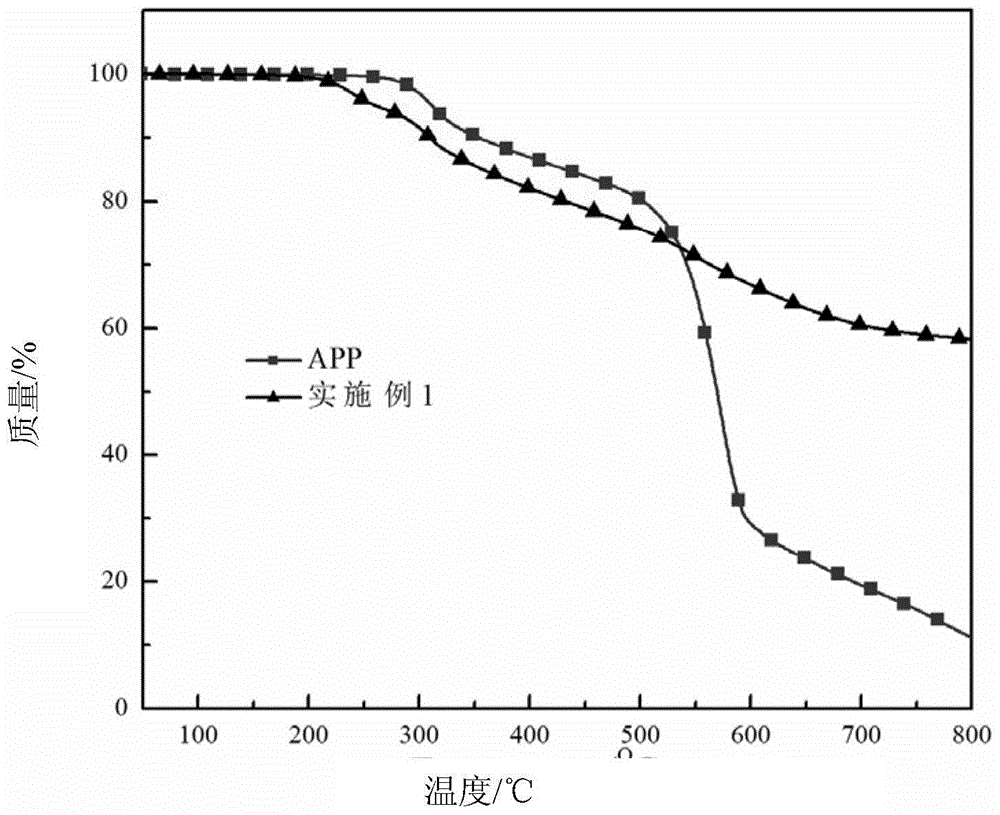

[0030] (2) Take 7.00g of microcrystalline cellulose, dissolve it in 61.25g of 64% concentrated sulfuric acid, st...

Embodiment 2

[0032] Prepare the nanocellulose surface modified core-shell structure flame retardant according to the following steps:

[0033] (1) At room temperature, add 5.00 g of melamine and 9.00 mL of formaldehyde solution with a mass concentration of 37% to a three-necked flask containing 50.00 mL of deionized water, add dropwise sodium hydroxide solution to adjust the pH value to 8-9, stir and heat up After reaching 70°C, keep stirring and heat-preserve for 40 minutes. After the reaction is complete, an emulsified liquid is obtained, which is cooled to room temperature; the cooled emulsified liquid is added to a flask containing 60.00 g of APP, and 80.00 mL of ethanol solution is added to stir, drop Add formic acid solution to adjust the pH value to 3-4, slowly heat to 60°C, keep warm at this temperature for 1 hour, then stir to cool down, filter with suction, wash, dry, and finally get a white powder;

[0034] (2) Take 12.00g of microcrystalline cellulose, dissolve it in 105.00g of...

Embodiment 3

[0036] Prepare the nanocellulose surface modified core-shell structure flame retardant according to the following steps:

[0037] (1) Add 5.00g of melamine and 9.00mL of mass concentration of 37% formaldehyde solution at room temperature to a three-necked flask containing 50.00mL of deionized water, add dropwise sodium carbonate solution to adjust the pH value to 8~9, stir and heat up to After 70°C, keep stirring and keep warm for 40 minutes. After the reaction is complete, an emulsified liquid is obtained and cooled to room temperature; add the cooled emulsified liquid to a flask containing 60.00g of APP, add 150.00mL of ethanol solution to stir, add dropwise Adjust the pH value of the formic acid solution to 3-4, slowly heat to 80°C, keep warm at this temperature for 2 hours, then stir to cool down, filter with suction, wash and dry, and finally get a white powder;

[0038] (2) Take 16.00g of microcrystalline cellulose, dissolve it in 140.00g of 64% concentrated sulfuric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com