Preparation method of titanium dioxide

A technology of titanium dioxide and titanium tetrafluoride, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of difficult research and development, large environmental pollution, and high consumption of sulfuric acid, achieve green environmental protection technology, reduce production costs, and solve Flammable and explosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of titanium dioxide in this embodiment is specifically: 1.42kg of titanium tetrafluoride gas is hydrolyzed with 0.41kg of water vapor at 600°C for 0.5 hours to generate 1.0kg of gas-phase titanium dioxide primary particles and 0.95kg of hydrogen fluoride; 1.0kg of titanium dioxide is produced once The particles are aggregated into aggregated particles through the concentrator, and then separated by cyclone, deacidified by two-stage air jet, and screened by ebullating bed to obtain 0.85kg of titanium dioxide. Wherein titanium tetrafluoride is commercially available.

Embodiment 2

[0027] The preparation method of titanium dioxide in this embodiment is specifically: 1.35kg of titanium tetrafluoride gas is hydrolyzed with 0.39kg of water vapor at 200°C for 2 hours to generate 0.95kg of gas-phase titanium dioxide primary particles and 0.9kg of hydrogen fluoride; 0.95kg of titanium dioxide once The particles are aggregated into aggregated particles through the concentrator, and then separated by cyclone, deacidified by two-stage air jet, and screened by ebullating bed to obtain 0.8kg of titanium dioxide. Wherein titanium tetrafluoride is commercially available.

Embodiment 3

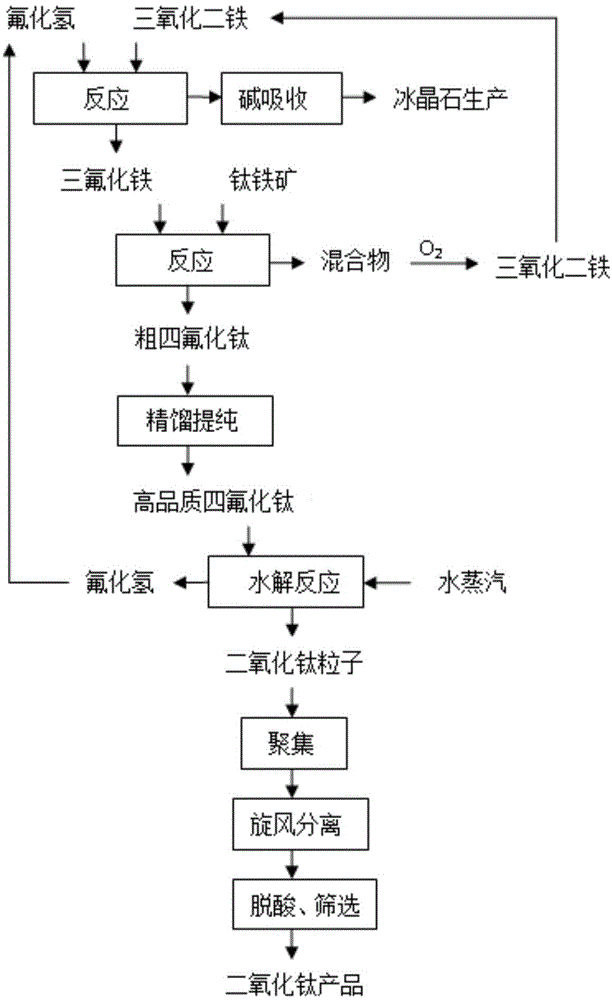

[0029] The preparation method of present embodiment titanium dioxide, specific technological process is as follows figure 1 As shown, the specific operation steps are as follows:

[0030] 1) React 50 mol of anhydrous hydrogen fluoride with 8 mol of ferric oxide in a fluidized bed at 500°C for 0.2 hours to obtain 2.2 kg of ferric trifluoride solid, and produce 0.55 kg of fluorine-containing water vapor as a by-product after being absorbed by sodium hydroxide solution cryolite;

[0031] 2) 2.2kg of ferric trifluoride obtained in step 1) is mixed with ilmenite, wherein the molar ratio of ferric trifluoride and ferric titanate in ilmenite is 4.5:3.0, and placed in a rotary kiln at 1500°C for 5 hour, generate 1.55Kg titanium tetrafluoride crude gas, and obtain 1.42kg high-quality titanium tetrafluoride gas after rectification and purification; wherein the by-product ferric oxide and ferrous oxide mixture reacts with oxygen to produce ferric oxide return to step 1);

[0032] 3) 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com