Processing method of copper alloy target material

A processing method, copper alloy target technology, applied in metal material coating process, ion implantation plating, coating, etc., to achieve the effect of inhibiting electromigration, improving stability and uniformity, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

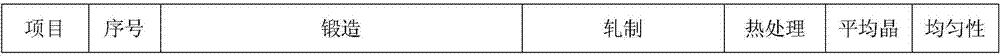

[0021] The specification of the copper alloy ingot is φ150×130t, hot forging is carried out at 350-600°C, the forging method is X / Y / Z three-direction upsetting and drawing, the upsetting and drawing ratio is 2:1, and the final forging temperature is 450°C , the deformation of the cold rolling pass is 15%, and the rolling is φ400×18t after cold rolling;

[0022] Then recrystallization heat treatment is carried out under the condition of 400℃ / 2h, and the target blank is rapidly cooled to make a target material, which is processed into a φ380×15t target blank by machining, and then it is bonded to the copper alloy back plate by diffusion welding Welded to make a sputtering target.

[0023] The results obtained are shown in Table 1. It can be seen that the average grain size of the sputtering target obtained after hot forging in the range of 350°C to 600°C and then cold rolling heat treatment is below 30 μm. As the forging temperature increases, The average grain size increases g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com