Steel wire rod for furniture spring and production method thereof

A steel wire rod and furniture technology, applied in the direction of improving process efficiency, etc., can solve the problems of reducing plastic toughness, deteriorating the fatigue resistance of spring steel, and easily forming inclusions, etc., to reduce production and processing costs, save heat treatment costs, comprehensive good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

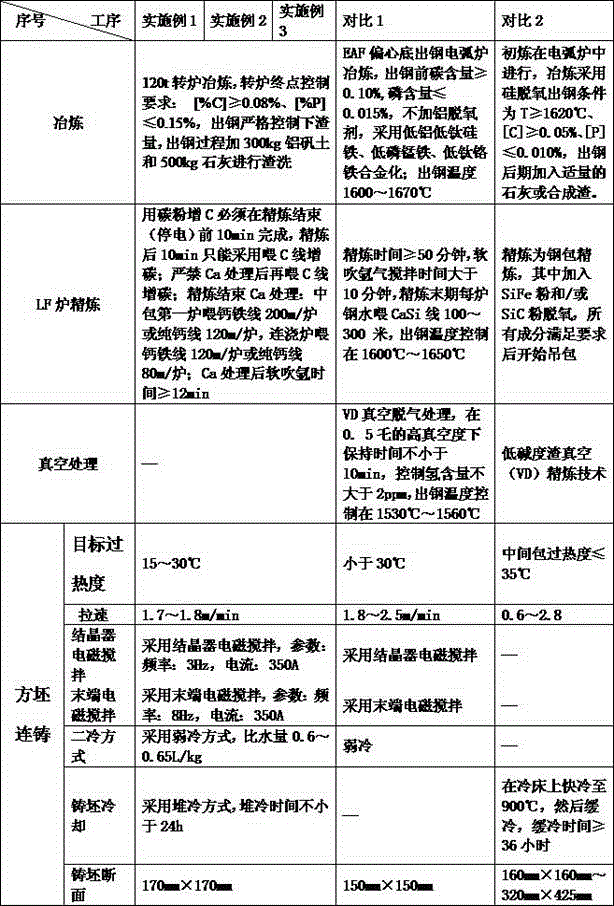

[0022] The method for preparing the steel wire rod for furniture springs includes the following steps:

[0023] A. 120t converter smelting: According to the weight percentage of the above main components, the converter end point control requirement is [C]≥0.08%, [P]≤0.15%, and the amount of slag is strictly controlled during the tapping process. 300kg bauxite and 500kg are added during the tapping process. Lime for slag washing;

[0024] B. LF furnace refining: add silicon carbide or ferrosilicon powder for diffusion deoxidation in the early stage to ensure rapid white slag production; add lime, bauxite, fluorite (ball) during the refining process to adjust the amount of slag and slag fluidity; use carbon powder The C increase must be completed 10 minutes before the end of refining (power failure), and the C line can only be used to increase carbon 10 minutes after refining; it is strictly forbidden to feed the C line to increase carbon after the Ca treatment; after the refining, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com