Manufacturing method of welding type cylinder block of marine diesel engine

A technology of marine diesel engine and manufacturing method, which is applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of the influence of fatigue life of welding seam, large plate thickness drop, large welding stress, etc., and achieves easy repair and reduction of defects The effect of cold cracking and reducing production and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The manufacturing method of the welded cylinder block of the marine diesel engine of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention cannot be limited by this.

[0033] Step 1. Platform marking

[0034] 1.1. Before marking the line, the levelness of the platform should be checked first (to ensure that the width of the platform is within 6 meters and the length of 12 meters, the levelness error is ≤ 2mm,), because the levelness of the platform will directly affect the verticality of the parts and the bottom and panel machining allowance.

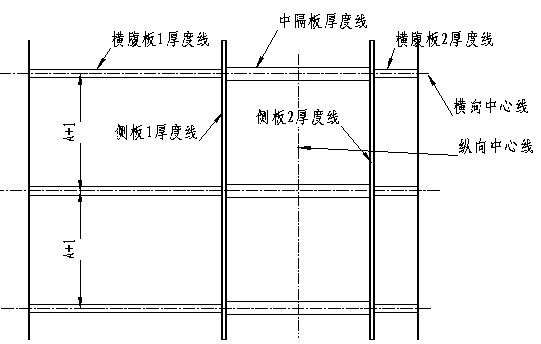

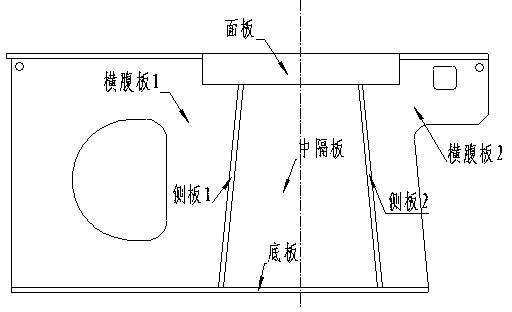

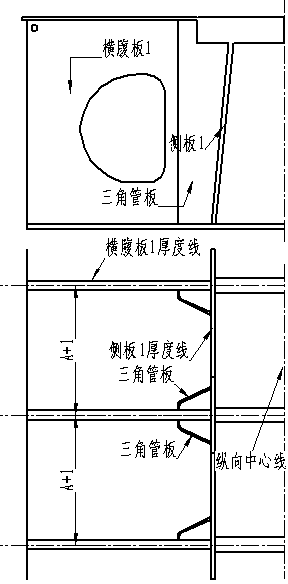

[0035] 1.2 Determine the datum plane for assembling the cylinder block on the platform, that is, take the bottom plate of the cylinder block as the datum plane, and then determine the installation marking line of the cylinder block on the platform, see figure 1 : Longitudinal centerline, transverse centerlin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com